Patents

Literature

35results about How to "Good corrosion resistance and aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-power high-stability cable material and preparation method thereof

InactiveCN104559203AStable chemical propertiesGood physical and mechanical propertiesRubber insulatorsFiberPolyvinyl chloride

The invention discloses a high-power high-stability cable material which is prepared from the following raw materials in parts by weight: 6-8 parts of oxidized polyethylene wax, 15-25 parts of PVC (polyvinyl chloride) resin, 3-4 parts of epoxy soybean oil, 3-5 parts of soluble polytetrafluoroethylene, 2-4 parts of nano titanium dioxide, 5-7 parts of ethylene-octylene copolymer, 3-4 parts of carbon fiber, 2-3 parts of benzotriazole, 4-5 parts of red phosphorus, 2-3 parts of nano graphite, 1-2 parts of accelerator CZ, 45-55 parts of nitrile silicone rubber, 6-7 parts of nano calcium carbonate, 2-5 parts of maleic anhydride grafted polypropylene and 8-12 parts of filler. The cable material has favorable chemical property stability, physical and mechanical properties, electrical insulation properties, aging resistance and flame retardancy, and can satisfy the demands for cable manufacturing industry.

Owner:HUAINAN WENFENG AEROSPACE CABLE CO LTD

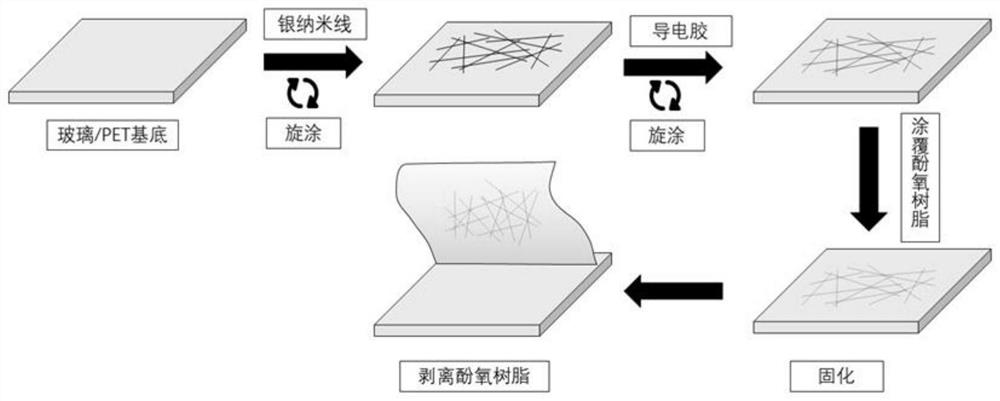

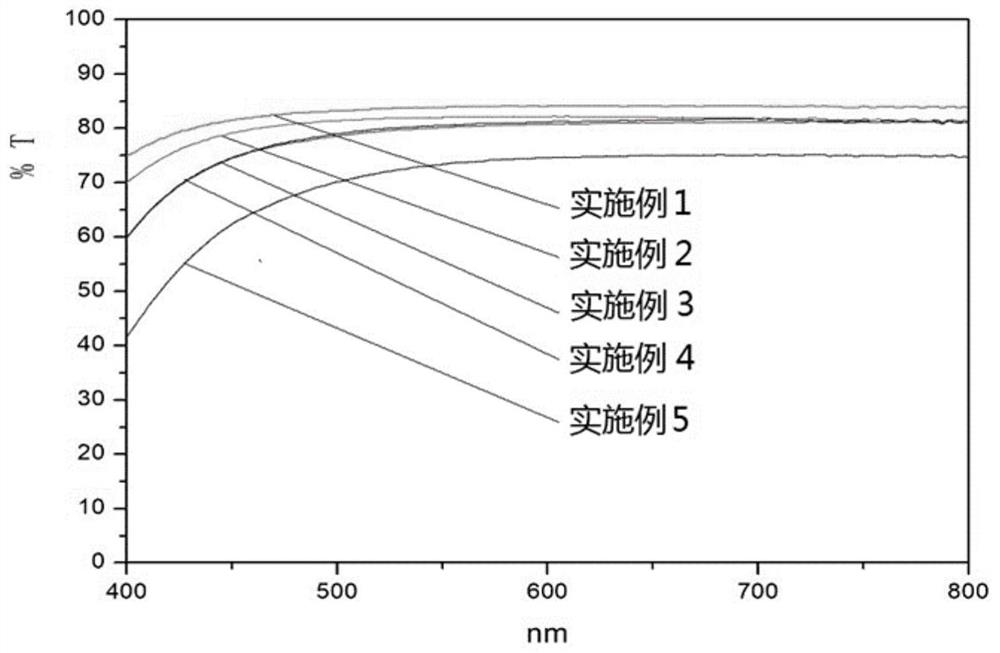

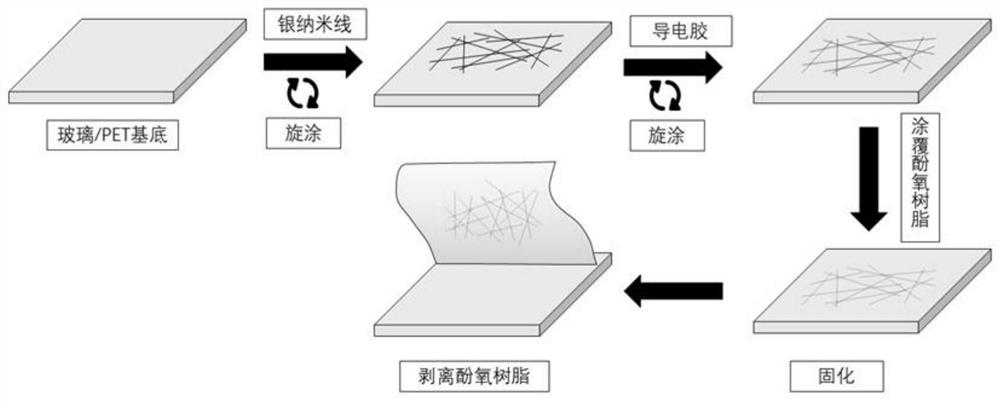

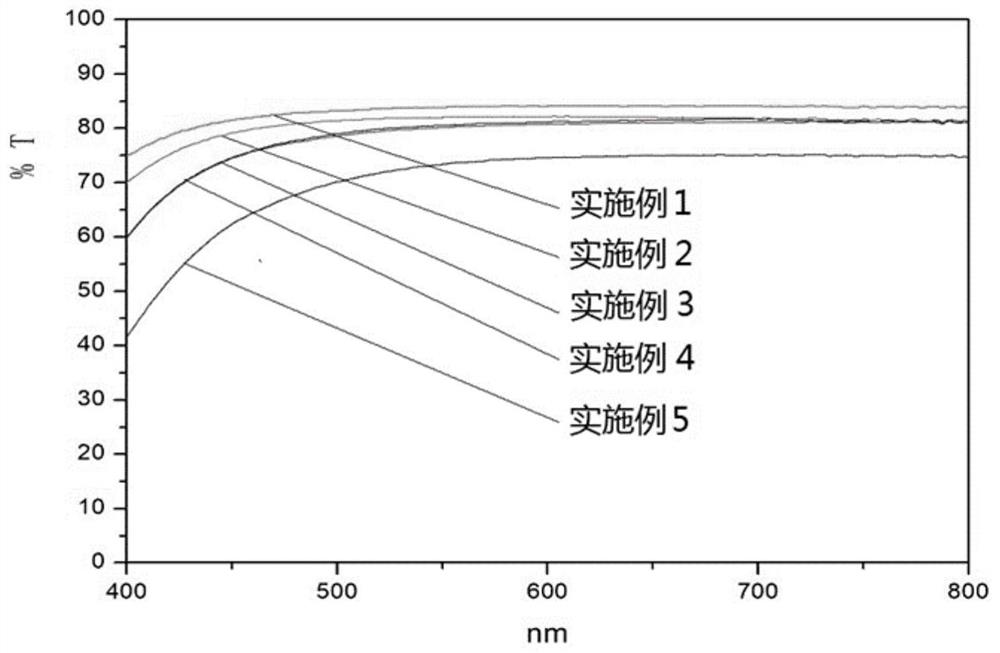

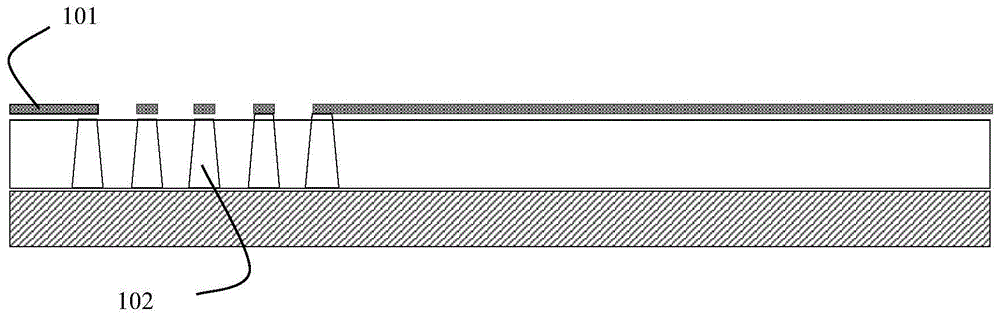

Preparation method of silver nanowire flexible transparent conductive film based on phenoxy resin

ActiveCN111627613AHigh transparencyGood light transmissionConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersFilm baseHigh surface

The invention provides a preparation method of a silver nanowire flexible transparent conductive film based on phenoxy resin. The method comprises the following steps: coating a cleaning substrate with a dispersion liquid containing silver nanowires, and drying the dispersion liquid to obtain a silver nanowire conductive network layer on the substrate; coating a layer of transparent conductive adhesive on the silver nanowire layer to serve as a protective layer; drying the conductive adhesive, coating a layer of phenoxy resin solution on the conductive adhesive, and carrying out drying again to remove a solvent; and stripping the dried composite conductive film from the substrate to obtain the flexible transparent conductive film with low resistance and high flatness. According to the invention, the phenoxy resin is used as the flexible base material, and the transparent conductive adhesive layer is introduced between the phenoxy resin and the silver nanowire layer, so that the effectsof increasing the adhesion between the flexible base material and the silver nanowire layer and protecting the silver nanowire layer from oxidation are achieved. The problems of poor adhesion betweenthe silver nanowire conductive layer and other flexible substrates and high surface roughness and resistance value of the flexible conductive film in the existing preparation method are solved, and the preparation method has practical application value.

Owner:WUHAN UNIV OF TECH

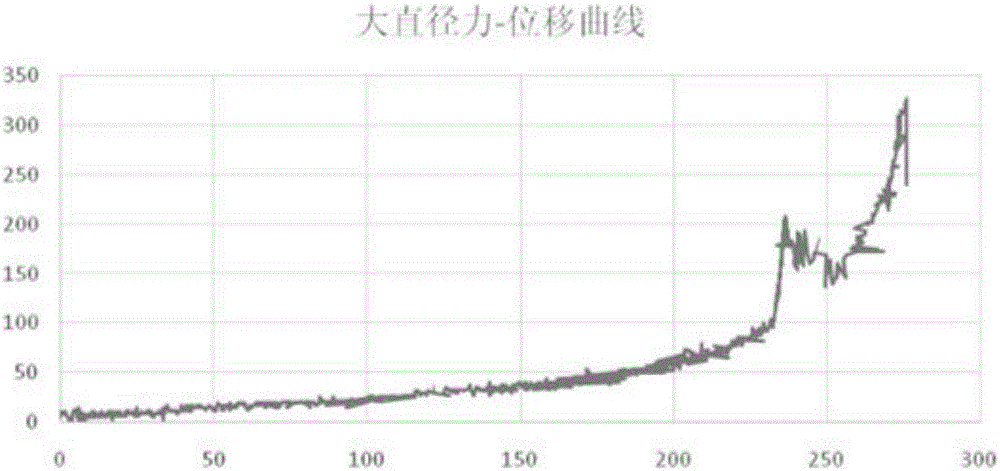

High-strength composite elastic energy-absorption anti-collision device and production method thereof

InactiveCN106426974ALarge compression deformationSmall reaction forceClimate change adaptationDomestic articlesFiberAbsorption capacity

The invention relate to a high-strength composite elastic energy-absorption anti-collision device and a production method thereof. The anti-collision device comprises a steel tube, a macromolecular close-cell type foam material core, a high-strength fiber material layer, a composite fiber strengthening layer and an SPUA casting coating, which are arranged from inside to outside in sequence, wherein the axial peripheral surface of the steel tube is coated with the macromolecular close-cell type foam material core; and the axial peripheral surface of the macromolecular close-cell type foam material core is coated with the high-strength fiber material layer. The production method comprises the following steps: manufacturing a macromolecular close-cell foam material through a mould, and placing the steel tube in the macromolecular close-cell foam material as a strengthening structure, with an overall size meeting an actual requirement; performing mould-free 3D casting with a rotary casting machine, including casting bottom-layer high-strength fiber with a 3D flat nozzle; performing mould-free 3D casting with the rotary casting machine, including casting the composite fiber strengthening layer with a round nozzle; and finally, manually casting the SPUA surface coating, and forming the SPUA surface coating through natural-temperature curing. The high-strength composite elastic energy-absorption anti-collision device has the advantages of large compressive deformation, small counter force, high energy-absorption capacity, excellent anti-corrosion and anti-aging properties, self-floating property, easiness in mounting, no maintenance, long service life and the like.

Owner:南京正隆顺达高分子材料有限公司

High-strength corrosion-resistant wood-plastic composite material and method for preparing same

The invention discloses a high-strength corrosion-resistant wood-plastic composite material and a method for preparing the same. The high-strength corrosion-resistant wood-plastic composite material comprises, by weight, 25-30 parts of wood powder, 30-35 parts of ABS (acrylonitrile butadiene styrene), 20-25 parts of PVC (polyvinyl chloride), 3-5 parts of maleic anhydride grafted polyethylene, 1-2 parts of ACR (acrylic ester), 10-15 parts of 800-mesh feldspar powder, 0.3-0.7 part of stearate, 0.8-1.5 parts of terpene resin and 1-3 parts of auxiliaries. The high-strength corrosion-resistant wood-plastic composite material and the method have the advantages that the wood-plastic composite material prepared by the aid of the method is good in strength, corrosion resistance and aging resistance and excellent in processability and long in service life, and accordingly the high-strength corrosion-resistant wood-plastic composite material and the method have excellent application prospects.

Owner:苏州雅晟建筑装饰工程有限公司

High-fire-resistance cable material for high power and preparation method thereof

InactiveCN105001562AEasy to processExcellent electrical propertiesRubber insulatorsInsulated cablesTert-butyl peroxybenzoateDibenzoyl Peroxide

The invention discloses a high-fire-resistance cable material for high power. The high-fire-resistance cable material comprises, by weight, 3-5 parts of calcium carbonate, 6-8 parts of ethylene-octene copolymer, 25-35 parts of powder acrylonitrile-butadiene rubber, 20-30 parts of ethylene-octene copolymer resin, 30-40 parts of fluoride rubber, 4-5 parts of polyethylene glycol, 3-5 parts of ethylene-ethyl acrylate copolymer, 2-4 parts of kaolin, 2-3 parts of hydrazide, 3-4 parts of dibenzoyl peroxide, 1-3 parts of 2-methyl methacrylate, 2-3 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 1-2 parts of zinc oxide, 2-4 parts of tert-butyl peroxybenzoate and 8-12 parts of filler. The cable material has the good machining performance, and the added tetrafluoroethylene-hexafluoropropylene copolymer enables the product to have excellent electrical characteristics, excellent fire resistance and excellent high temperature and low temperature resistance.

Owner:安徽电信器材贸易工业有限责任公司

Solvent-resistant cable material for large power and preparation method thereof

InactiveCN105017580AReasonable designIncrease profitRubber insulatorsDiisodecyl phthalatePOLYETHYLENE WAX

The invention discloses a solvent-resistant cable material for large power and a preparation method thereof. The solvent-resistant cable material comprises, by weight, 1-2 parts of an antiager MB, 3-5 parts of epoxidized soybean oil, 4-6 parts of ethylene dimethacrylate, 30-50 parts of nitrile rubber, 2-4 parts of an ethene-propylene-butylene ternary copolymer, 2-4 parts of light calcium carbonate, 3-5 parts of zinc stearate, 2-5 parts of magnesium hydroxide, 3-4 parts of tetra[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol, 2-4 parts of calcined clay, 3-6 parts of polyethylene wax, 5-8 parts of diisodecyl phthalate, 2-4 parts of sodium pyrosulfite, 15-25 parts of isoprene rubber and a filler. The preparation method has a reasonable design, can be operated simply, and has a high raw material utilization rate. The solvent-resistant cable material has the characteristics of heat resistance, weatherability and solvent resistance and excellent wear resistance and can be widely used in the field of power cables.

Owner:ANHUI TELI SCI & TECH

Large-power rat-ant-resisting cable material and preparation method thereof

The invention discloses a large-power rat-ant-resisting cable material. The cable material is prepared from the following raw materials, by weight part: 15-20 of carbon black, 2-3 of zinc stearate, 1-3 of magnesium hydroxide, 3-5 of soda ash, 4-5 of dioctyl adipate, 40-50 of fluorubber, 4-6 of zinc borate, 3-5 of clay, 4-6 of lindane, 2-4 of hexachlorocyclotriphosphazene, 3-5 of ferrocene, 2-4 of a cross-linking agent of 3-aminopropyltrimethoxy silane, 3-5 of polyethylene wax, 10-12 of fumed silica, and 8-12 of a filler. The cable material causes no pollution to the environment, and has excellent abrasive resistance and mechanical properties. The added lindane can kill termites through contact and can prevent rats from gnawing the cable material.

Owner:安徽电信器材贸易工业有限责任公司

Easily processable cable material for large power and preparation method thereof

The invention discloses an easily processable cable material for large power and a preparation method thereof. The easily processable cable material is prepared from 3-4 parts by weight of paraffin, 2-4 parts by weight of nanometer barium sulfate, 6-8 parts by weight of an ethene / vinyl acetate copolymer, 3-5 parts by weight of bis(P,P-bis-ethylhexyldiphosphato)ethanediolatotitanate, 2-4 parts by weight of expandable graphite, 2-3 parts by weight of active aluminum hydroxide, 40-50 parts by weight of high strength polyethylene resin, 4-5 parts by weight of benzoyl peroxide, 2-3 parts by weight of an antistatic agent SN, 3-5 parts by weight of limestone, 4-6 parts by weight of fatty acid amide, 4-5 parts by weight of wicker fibers, 2-3 parts by weight of nanometer bentonite, 1-2 parts by weight of an antiager DNP and 8-12 parts by weight of a filler. The easily processable cable material has good processing performances and no peculiar smell. Through use of the bis(P,P-bis-ethylhexyldiphosphato)ethanediolatotitanate, cable material impact resistance and fluidity are improved.

Owner:ANHUI TELI CABLE

High-mechanical-performance cable material for high power and preparation method thereof

InactiveCN105001527AGood corrosion resistance and aging resistanceExcellent heat sublimation resistanceLinear low-density polyethylenePhosphate

The invention discloses a high-mechanical-performance cable material for high power and a preparation method thereof. The high-mechanical-performance cable material comprises, by weight, 2-3 parts of stearic acid, 2-4 parts of activated magnesium hydrate, 3-5 parts of silicon dioxide powder, 2-3 parts of pyrophyllite powder, 3-5 parts of tris(2-ethylhexyl) phosphate, 2-4 parts of talcum powder, 45-65 parts of ethylene propylene diene monomer, 1-3 parts of 2-(2H-benzotriazol-2-yl)-4,6-di-tert-pentylphenol, 1-2 parts of antioxidant TPP, 15-20 parts of linear low-density polyethylene, 3-5 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 2-4 parts of sodium sulfonate, 2-4 parts of polycarbonate, 2-3 parts of m-xylylenediamine and 8-12 parts of filler. The high-mechanical-performance cable material has the excellent heat-resisting sublimability, launderability, gas fading resistance, mechanical performance retainability, and the added2-(2H-benzotriazol-2-yl)-4,6-di-tert-pentylphenol and antioxidant TPP are used together to achieve a remarkable synergistic effect.

Owner:安徽电信器材贸易工业有限责任公司

Wear-resistant cable material for large power and preparation method thereof

InactiveCN105061875AImprove mechanical propertiesGood chemical resistancePlastic/resin/waxes insulatorsBenzenePOLYETHYLENE WAX

The invention discloses a wear-resistant cable material for large power and a preparation method thereof. The wear-resistant cable material is prepared from 15-20 parts by weight of a waste ball material, 35-45 parts by weight of EVA resin, 3-4 parts by weight of zinc stearate, 2-4 parts by weight of oligomer ester, 3-5 parts by weight of dioctyl terephthalate, 4-6 parts by weight of polyethylene wax, 10-16 parts by weight of acrylic acid-grafted polyethylene, 5-6 parts by weight of vinyl benzene, 4-6 parts by weight of polyether-ether-ketone, 4-6 parts by weight of lauryl diethanolamide, 3-4 parts by weight of quartz sand, 4-5 parts by weight of disalicylideneethylenediamine, 15-25 parts by weight of precipitated white carbon and 8-12 parts by weight of a filler. The wear-resistant cable material has good mechanical properties, wear resistance, chemical resistance and hydrolysis resistance. Through use of polyether-ether-ketone, the wear-resistant cable material does not shrink at a high temperature under high pressure.

Owner:安徽电信器材贸易工业有限责任公司

Novel environmental-protection cable material for high power and preparation method thereof

InactiveCN105061934AEasy to prepareExcellent pull and tensionPlastic/resin/waxes insulatorsAmmonium polyphosphatePolypropylene

The invention discloses a novel environmental-protection cable material for high power; the cable material is prepared from the following raw materials in parts by weight: 45-65 parts of PVC resin, 8-10 parts of pottery clay, 3-4 parts of ammonium polyphosphate, 2-4 parts of diatomite, 3-5 parts of polyethylene wax, 15-25 parts of carbon black N550, 3-4 parts of an anti-aging agent MB, 2-3 parts of polypropylene, 5-6 parts of amine polyphosphate, 2-4 parts of calcium stearate, 2-3 parts of tert-butyl peroxyacetate, 4-5 parts of thermoplastic polyurethane, 2-4 parts of calcium ferrite, 1-2 parts of 1,4-bis(tert-butyldioxyisopropyl)benzene, and 8-12 parts of a filling agent. The cable material is simple in preparation method, has excellent tension and tensile force, and has relatively strong toughness and aging resistance properties; and the selected raw materials are all the environmental protection materials, so that the cable material has no pollution to the environment.

Owner:安徽电信器材贸易工业有限责任公司

Water-resistant cold-resistant cable material for large power and preparation method thereof

The invention discloses a water-resistant cold-resistant cable material for large power. The water-resistant cold-resistant cable material is prepared from 3-5 parts of nanometer calcium carbonate, 40-60 parts of butadiene styrene rubber, 10-15 parts of high wear resistant carbon black, 3-5 parts of pentaerythritol, 10-13 parts of N330 carbon black, 1-2 parts of an antiager ODA, 3-4 parts of an ethene-methacrylate copolymer, 2-3 parts of melamine, 2-4 parts of zinc stearate, 4-6 parts of tert-butyl peroxybenzoate, 3-5 parts of sodium polyacrylate, 2-5 parts of butyl acrylate, 1-3 parts of zinc phosphate, 3-4 parts of ferrocene and 8-12 parts of a filler. The water-resistant cold-resistant cable material has excellent performances. Through use of butyl acrylate, product water resistance is improved, cable material internal plasticity is improved, a brittleness temperature is reduced and good cold resistance is obtained.

Owner:ANHUI TELI SCI & TECH

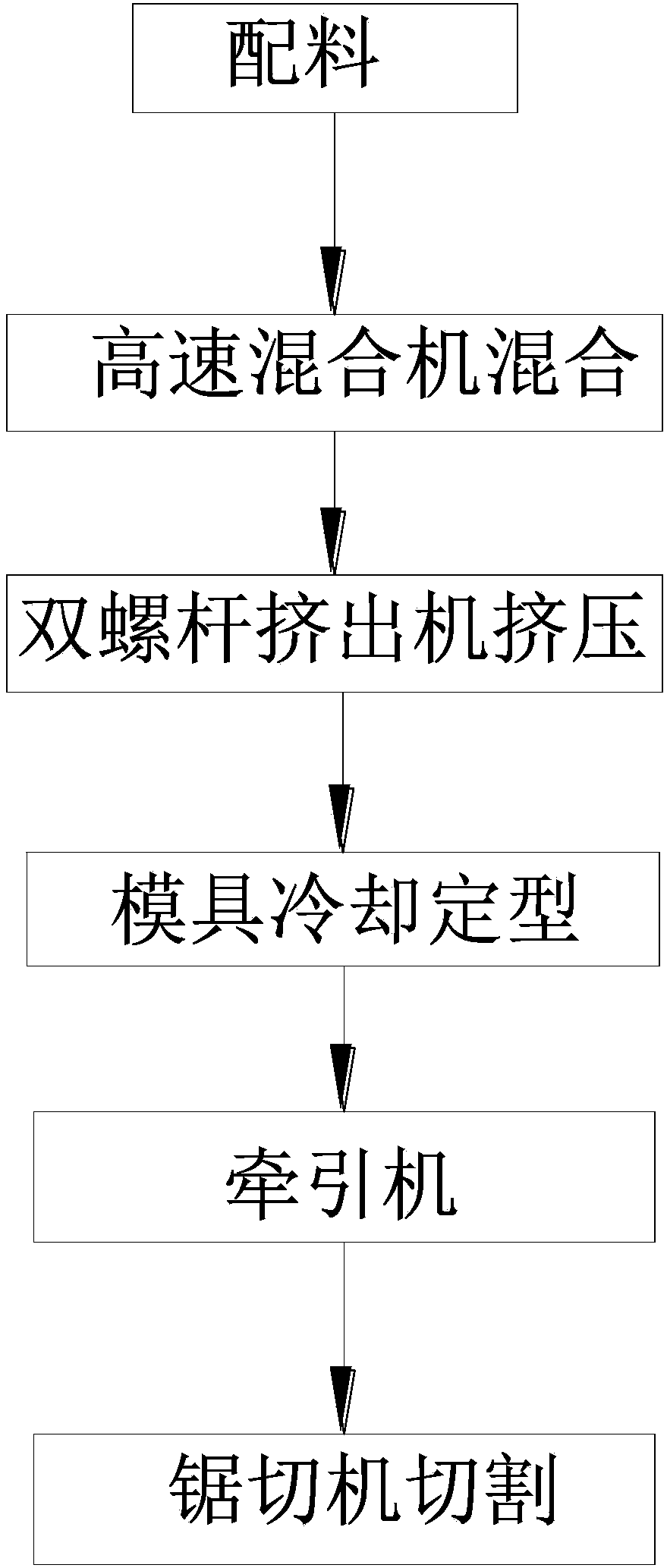

High-temperature-resistant CPVC plastic wood composite material

InactiveCN108129781AImprove high temperature resistanceGood corrosion resistance and aging resistanceFiberProcedure Agents

The invention provides a high-temperature-resistant CPVC (chlorinated polyvinyl chloride) plastic wood composite material. The composite material is prepared from the following components in percentages by weight: 30% of CPVC resin, 20% of PVCSG-8 resin, 20% of bamboo wood fiber powder, 10% of a light active calcium carbonate inorganic filler, 10% of a modifier, and 5% of a processing auxiliary agent; and the above components are mixed uniformly by utilizing a high-speed mixing machine, the mixing time is 1-2h, then the mixed components are extruded by using a twin-screw extruder, cooling shaping is performed by utilizing a mold matched with the twin-screw extruder, and after treatment is performed by utilizing a tractor, cutting is performed by utilizing a wood plate cutting machine to form composite material wood plates with different length specifications. According to the composite material provided by the invention, CPVC which is a engineering plastic with good high-temperature resistance and excellent aging resistance and corrosion resistance is specifically introduced, the high-temperature-resistant CPVC plastic wood composite material is prepared, and the use deformation temperature of the product is improved by 10 DEG C or more on the basis of conventional plastic wood.

Owner:GUANGZHOU HEFENG ENVIRONMENT FRIENDLY BUILDING MATERIALS CO LTD

High-flexibility cable material for high power and preparation method thereof

The invention discloses a high-flexibility cable material for high power. The high-flexibility cable material is prepared from, by weight, 1-2 parts of antiager D, 2-4 parts of nano calcium carbonate, 3-6 parts of polypropylene, 2-4 parts of petroleum wax, 2-3 parts of zinc oxide, 1-2 parts of antiager 4010, 1-2 parts of lead oxide phosphite hydrate, 3-5 parts of zinc borate, 4-5 parts of dilauryl thiodipropionate, 4-6 parts of ethylene bis stearamide, 6-8 parts of trioctyl trimellitate, 3-5 parts of sorbitan fatty acid ester, 40-50 parts of acrylic rubber, 2-4 parts of nanometer magnesia, and 8-12 parts of filler. According to the cable material, antiager D and antiager 4010 are adopted simultaneously, so that the heat resisting, antioxidation and bending, winding and fracturing resisting capacity of products are remarkably improved; meanwhile, sorbitan fatty acid ester and other materials are added, so that the cable material is high in flexibility and wide in market prospect.

Owner:安徽电信器材贸易工业有限责任公司

Low energy consumption cable material for large power and preparation method thereof

InactiveCN105061874AIncrease the degree of plasticizationEasy to processLinear low-density polyethyleneDioctyl terephthalate

The invention discloses a low energy consumption cable material for large power and a preparation method thereof. The low energy consumption cable material is prepared from 4-6 parts by weight of linear low density polyethylene, 20-30 parts by weight of polyvinyl chloride resin, 4-7 parts by weight of molybdenum disulfide, 3-5 parts by weight of boehmite, 10-15 parts by weight of methyl vinyl silicone rubber, 3-5 parts by weight of dioctyl terephthalate, 2-3 parts by weight of oxalyl dihydrazide, 2-4 parts by weight of nanometer magnesium-lanthanum alloy powder, 25-35 parts by weight of silicone rubber, 3-5 parts by weight of ethyoxy lauramide, 2-4 parts by weight of oil DOP, 4-5 parts by weight of purified dioctyl terephthalate, 3-6 parts by weight of an ethylene-vinyl acetate copolymer, 1-2 parts by weight of an antiager OD and 8-12 parts by weight of a filler. Through a reasonable formula and improved processes, the preparation method reduces production energy consumption. The low energy consumption cable material has a high plastification degree and excellent processing properties and is suitable for popularization application.

Owner:安徽电信器材贸易工业有限责任公司

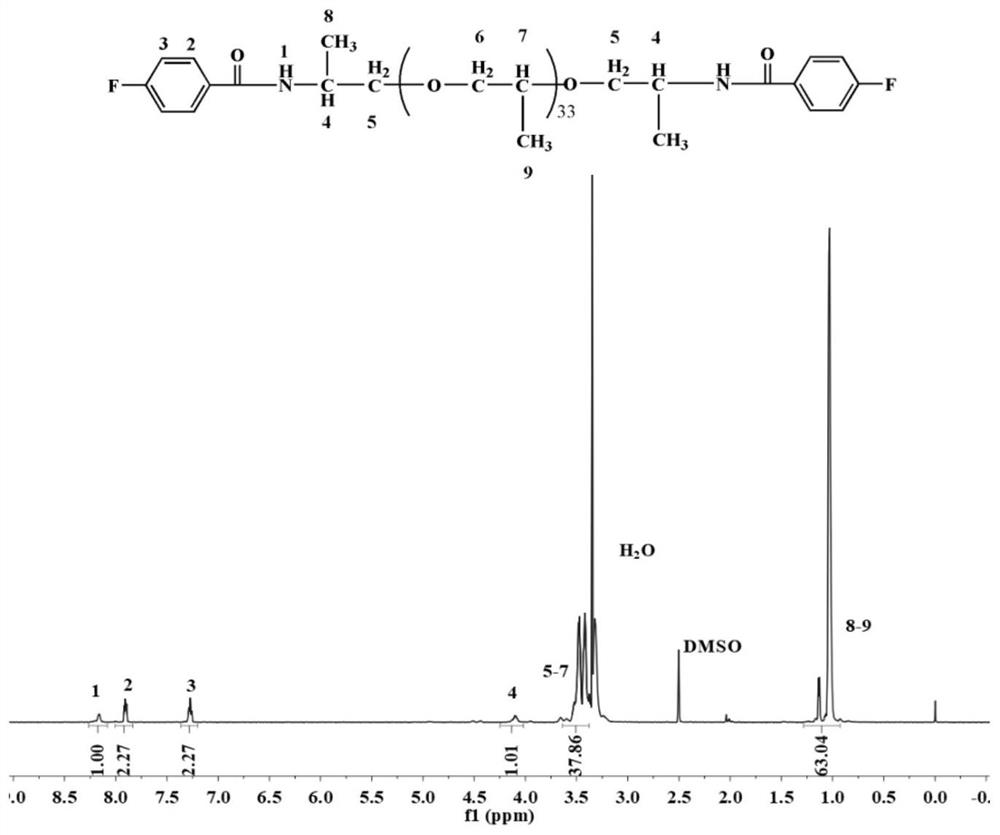

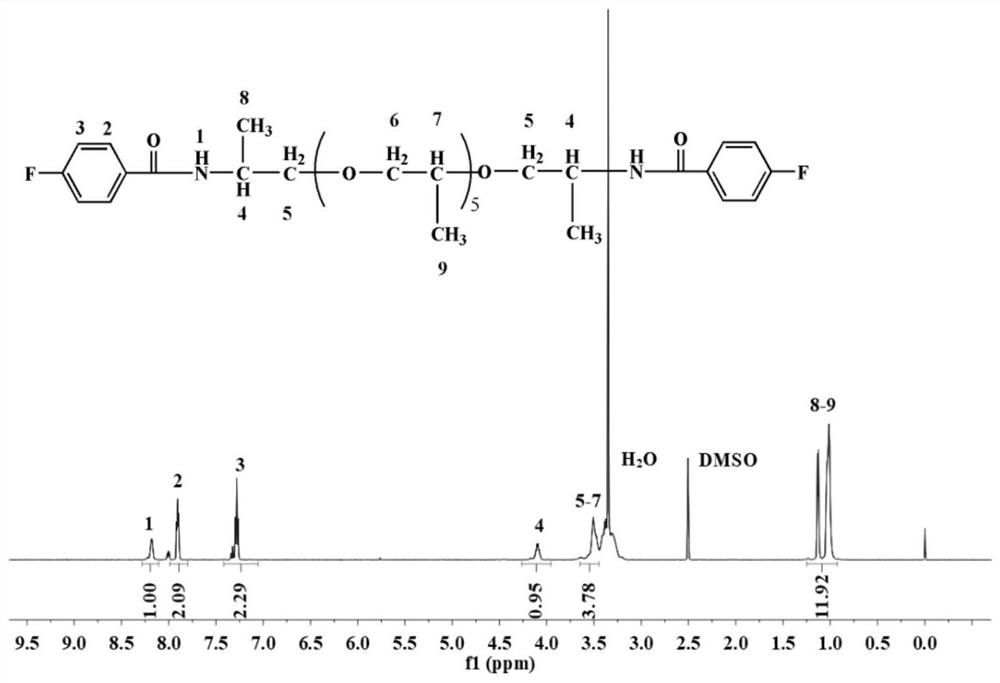

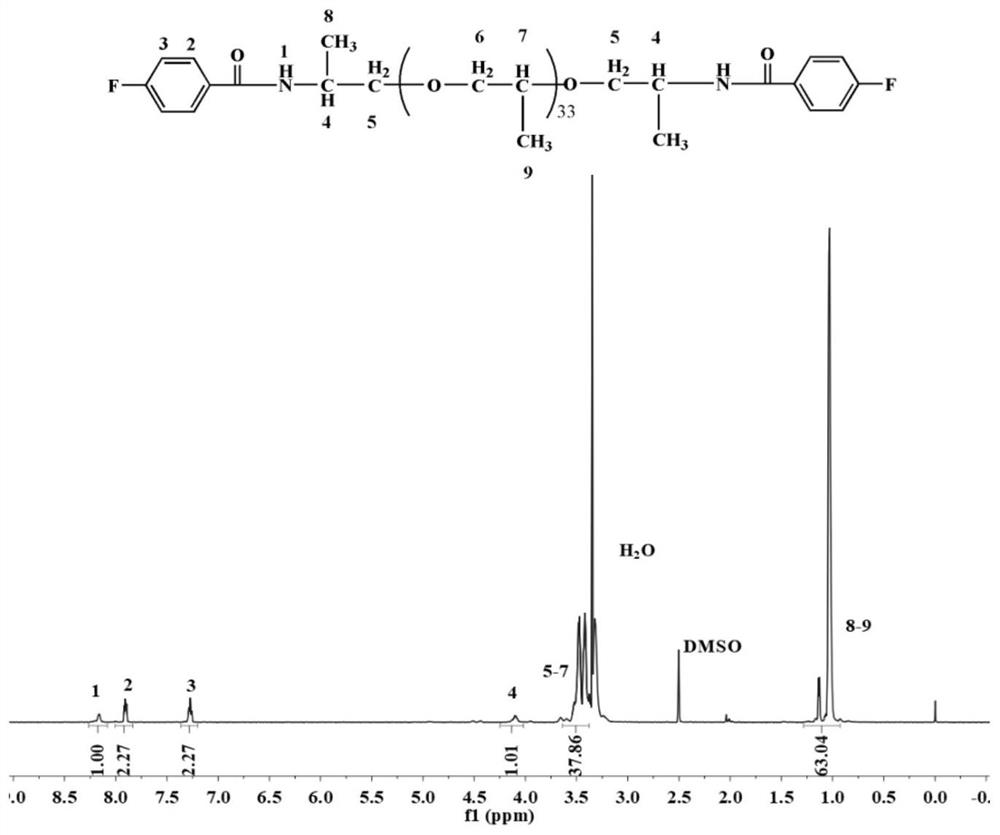

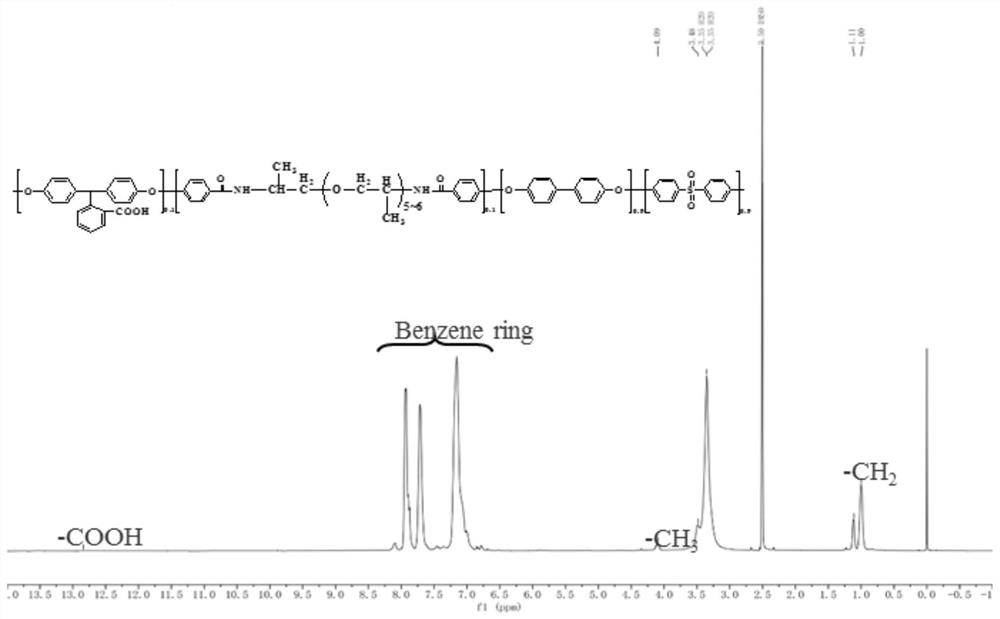

Fluorine-containing terminal group active hydroxyl friction-resistant high-shear-resistant composite rubber material

ActiveCN113416336AImprove thermal performanceImprove machinabilityCoatingsRubber materialPolymer science

The invention relates to a fluorine-containing terminal group active hydroxyl friction-resistant high-shear-resistant composite rubber material, and belongs to the field of friction-resistant materials. The invention provides a friction-resistant and high-shear-resistant composite rubber material. The friction-resistant and high-shear-resistant composite rubber material comprises the following raw materials in parts by weight: 0.1-10 parts of fluorine-containing terminal group active hydroxyl friction-resistant active surface modified resin and 50-90 parts of semi-vulcanized rubber, the structural formula of the fluorine-containing terminal group active hydroxyl friction-resistant active surface modified resin is as shown in formula I, m is more than 0 and less than or equal to 200, n is more than 0 and less than or equal to 200, and M is any one of perfluorohexyl sulfonyl, perfluorohexyl, perfluorohexyl sulfonyl, perfluorooctyl sulfonyl or perfluorooctyl. According to the invention, high-performance semi-aromatic polyether amide containing a fluorine-containing end group and an active hydroxyl grafting group is prepared, and the semi-aromatic polyether amide and traditional rubber are subjected to coating compounding by utilizing the excellent comprehensive performance of the semi-aromatic polyether amide, so that the friction performance of a rubber sealing element is improved.

Owner:SICHUAN UNIV +1

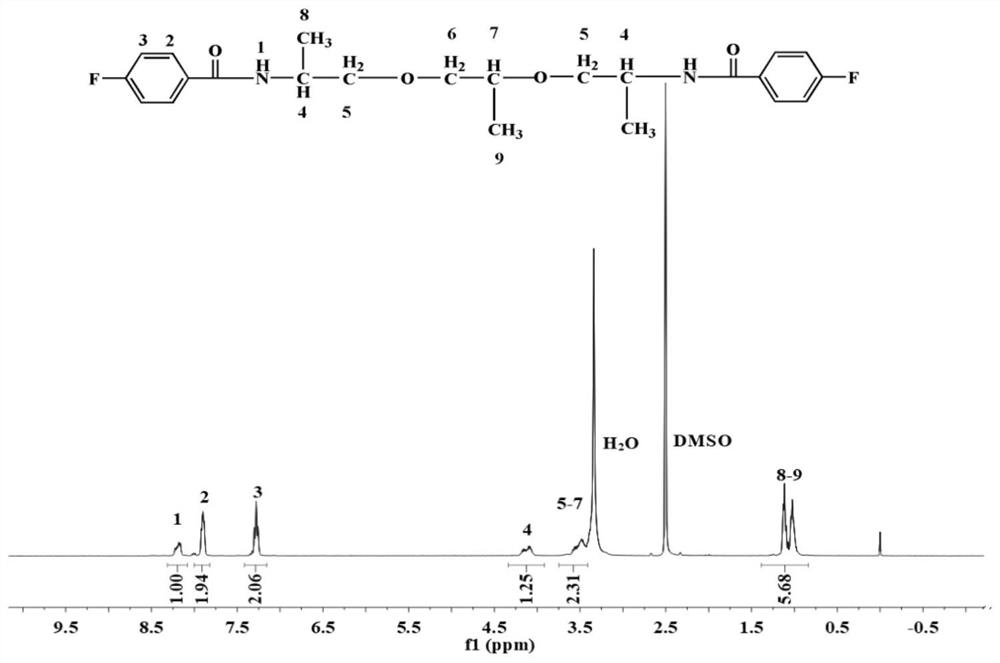

Preparation method of silver nanowire flexible transparent conductive film based on phenolic resin

ActiveCN111627613BHigh transparencyGood light transmissionConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersFilm baseThin membrane

The invention provides a method for preparing a flexible transparent conductive film of silver nanowires based on phenolic resin. A dispersion liquid containing silver nanowires is coated on a clean substrate, and after drying, a conductive network of silver nanowires is obtained on the substrate. layer; and then coating a layer of transparent conductive glue on the silver nanowire layer as a protective layer. After drying the conductive adhesive, coat a layer of phenolic resin solution on the conductive adhesive, and dry again to remove the solvent. The dried composite conductive film is peeled off from the substrate to obtain a flexible transparent conductive film with low resistance and high flatness. The present invention uses phenolic resin as the flexible substrate, and introduces a transparent conductive adhesive layer between it and the silver nanowire layer, so as to increase the bonding between the flexible substrate and the silver nanowire layer and protect the silver nanowire layer from oxidation . The method solves the problems of poor adhesion between the silver nanowire conductive layer and other flexible substrates and the large surface roughness and large resistance value of the flexible conductive film in the existing preparation method, and has practical application value.

Owner:WUHAN UNIV OF TECH

Corrosion-resistant printed circuit board and its preparation method

InactiveCN103687336BGood corrosion resistance and aging resistanceImprove corrosion resistanceElectrical connection printed elementsPrinted element electric connection formationSolder maskAging resistance

The invention discloses a manufacturing method of a corrosion-resistant printed wiring board. An outer layer of the printed wiring board comprises a golden finger area and a wiring area. The manufacturing method includes the following steps of (1) electroplating the whole board, (2) manufacturing the golden finger area, (3) attaching a dry film to cover the golden finger area and then manufacturing the wiring area and carrying out post-process manufacturing to obtain the corrosion-resistant printed wiring board. Resin is adopted to replace ink in the prior art to serve as a solder mask bridge to be filled between golden fingers. Because the resin has good corrosion resistance and ageing resistance, corrosion-resistant performance of the printed wiring board is greatly improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

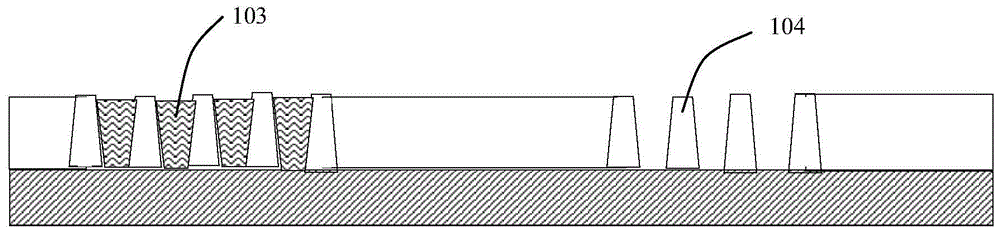

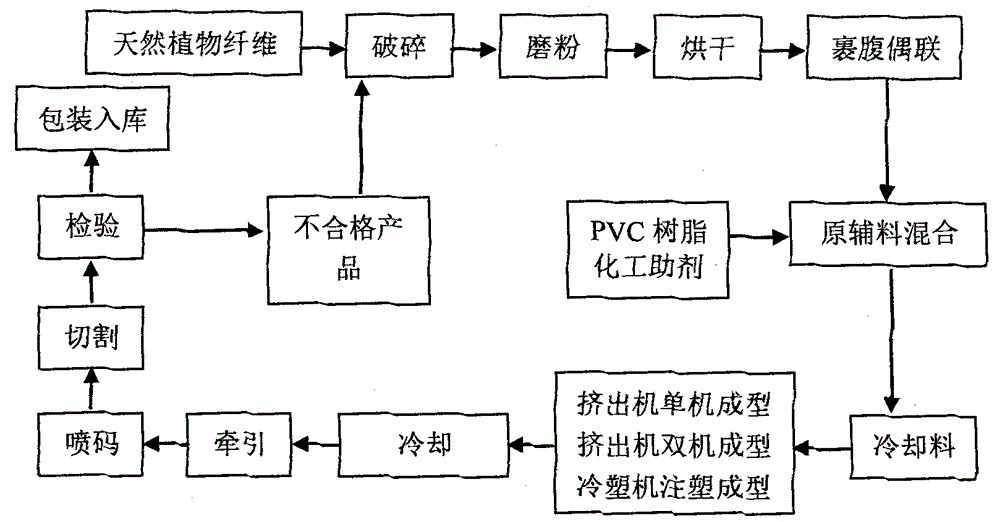

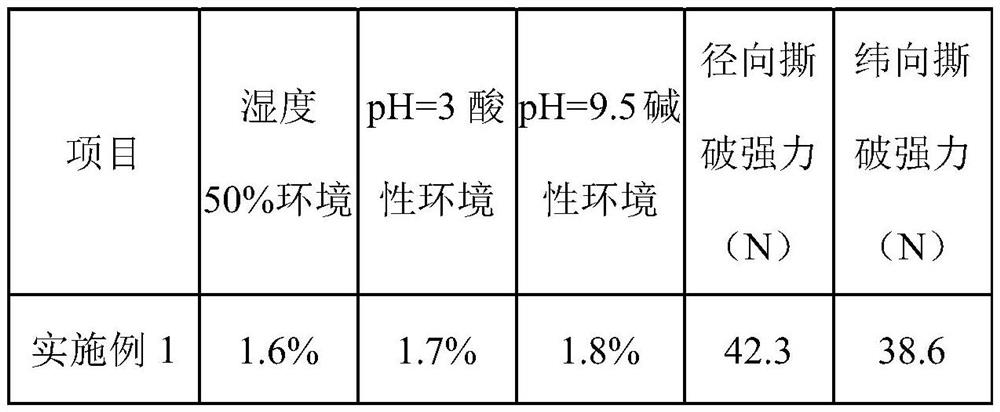

Method for producing wood plastic composite pipes and pipe fittings

ActiveCN102850692BSound reduction effect is goodIncrease profitSynthetic resin layered productsRigid pipesParaffin waxSodium bicarbonate

The invention relates to a method for producing wood plastic composite pipes and pipe fittings. The method comprises the following steps of breaking and crushing natural vegetable fibers into powder of 200 to 300 meshes, drying, adding an appropriate amount of a titanate coupling agent into the powder, carrying out wrapping coupling at a coupling temperature of 50 to 60 DEG C, adding 100 parts of a PVC resin, 20 parts of a filler calcium carbonate, 4 parts of a TK-238 composite lead stabilizer, 3 parts of 135A chlorinated polyethylene, 0.2 parts of 60# paraffin wax, 0.3 parts of stearic acid, 0.4 parts of lead stearate, 1 part of sodium bicarbonate, 0.8 parts of an azodicarbonamide foaming agent and 4 parts of an acrylate modifier into coupling products, mixing at a high speed of 2400 r / min at a mixing temperature of 100 to 110 DEG C, adding the mixture into a cold mixing machine, carrying out cold mixing at a cold mixing temperature of 40 to 50 DEG C, putting the cooled mixture obtained by cold mixing into a conical double-screw extruder or an injection molding machine, carrying out molding to obtain different types and specifications of the wood plastic composite pipes, pipe fittings or three-layer wood plastic silencing drain-pipes.

Owner:贵州国塑科技管业有限责任公司

Peculiar-smell-free heatproof cable material for large power and preparation method thereof

The invention discloses a peculiar-smell-free heatproof cable material for large power. The material is prepared from the following raw materials by weight: 50 to 60 parts of PVC resin type SG3, 2 to 4 parts of dolomite dust, 3 to 5 parts of (glycidyloxypropyl)trimethoxysilane, 5 to 6 parts of pentaerythritol, 3 to 5 parts of dicumyl peroxide, 4 to 5 parts of N,N'-di(beta-naphthyl)p-phenylenediamine, 2 to 4 parts of wollastonite, 3 to 4 parts of heavy calcium, 2 to 4 parts of silicone, 4 to 5 parts of ethylene-octylene copolymer, 2 to 3 parts of bis(t-butylperoxide)diisopropylbenzene, 3 to 5 parts of diphenylmethane bimaleimide, 2 to 4 parts of polyisobutylene, 2 to 3 parts of barium chromate and 8 to 12 parts of a filler. The cable material provided by the invention employs simple raw materials, is free of irritant stink, has excellent heat resistance and much lower smoke density compared with a common cable material, and is suitable for large-scale application.

Owner:ANHUI TELI CABLE

Corrosion-resistant anti-aging tarpaulin and preparation process thereof

PendingCN114541152AGood corrosion resistance and aging resistanceImprove product qualityTextiles and paperCorrosion resistantAcrylic fibre

The invention belongs to the technical field of tarpaulin, and particularly relates to corrosion-resistant anti-aging tarpaulin and a preparation process thereof. The tarpaulin comprises a base cloth layer, the base cloth layer is sequentially coated with a corrosion-resistant layer and a PVC fabric layer from the surface to the outside, and the base cloth layer is prepared from, by weight, acrylic fibers, nylon fibers and glass fibers; the corrosion-resistant layer is prepared from the following raw materials in parts by weight: carbon fibers, charcoal fibers, polyester, an antioxidant and an anti-ultraviolet agent; the raw materials of the PVC fabric layer comprise the following components in parts by weight: PVC paste resin, hydrotalcite, nano titanium dioxide, a plasticizer and a flame retardant. The tarpaulin has good corrosion resistance and aging resistance, the product quality is improved, and the market competitiveness of the product is improved.

Owner:山东永利新材料有限公司

Acid-modified potassium silicate-fluorocarbon modified styrene-acrylic emulsion composite coating and preparation method thereof

ActiveCN105504904BLow moisture absorptionImprove water resistanceAlkali metal silicate coatingsAnti-corrosive paintsEmulsionAging resistance

The invention discloses an acid-modified potash water glass-fluorocarbon-modified styrene-acrylic emulsion composite coating and a preparation method thereof. The composite coating comprises a matrix component, an assistant component and filler. The matrix component is prepared from, by weight, 20-30 parts of acid-modified potash water glass and 5-12 parts of fluorocarbon-modified styrene-acrylic emulsion. The acid-modified potash water glass is adopted, the moisture absorption of a matrix is effectively reduced, and the water resistance of the coating is improved; meanwhile, the fluorocarbon-modified styrene-acrylic emulsion has the advantages of being high in chemical corrosion resistance and artificial aging resistance and the like, and the overall use performance of the coating is greatly improved.

Owner:CHINA SHENHUA ENERGY CO LTD +1

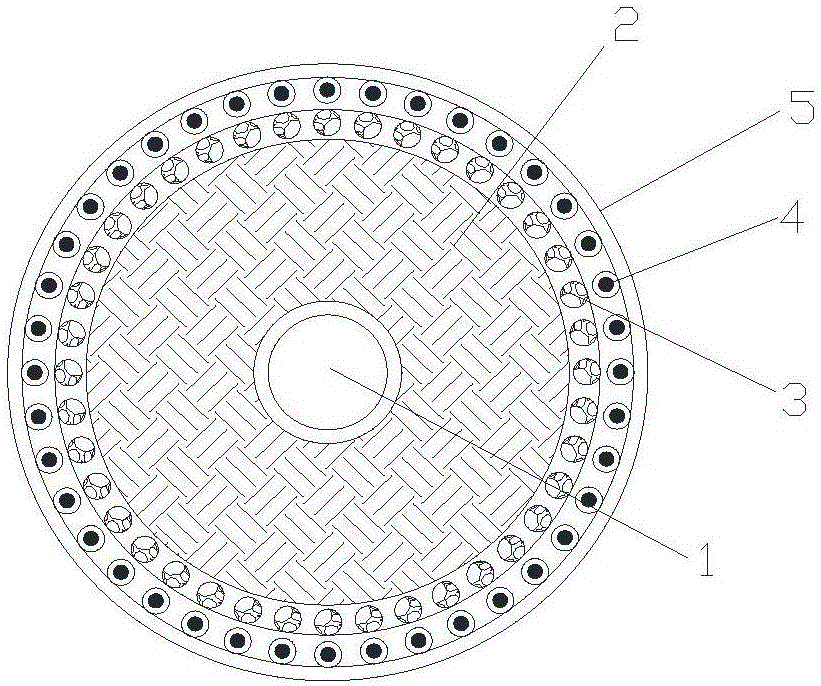

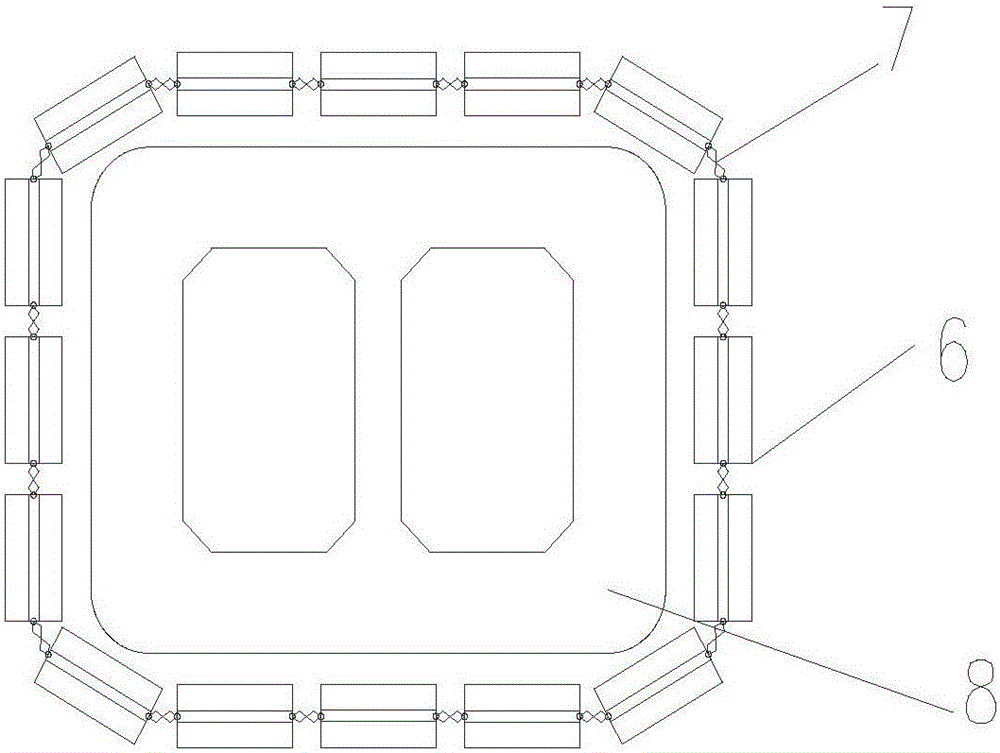

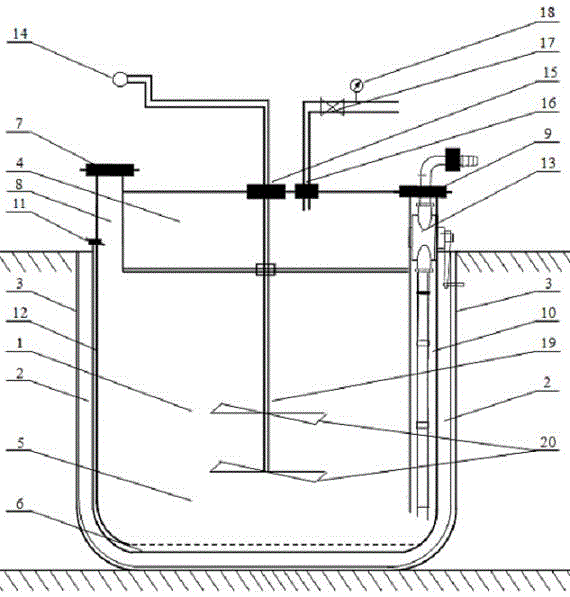

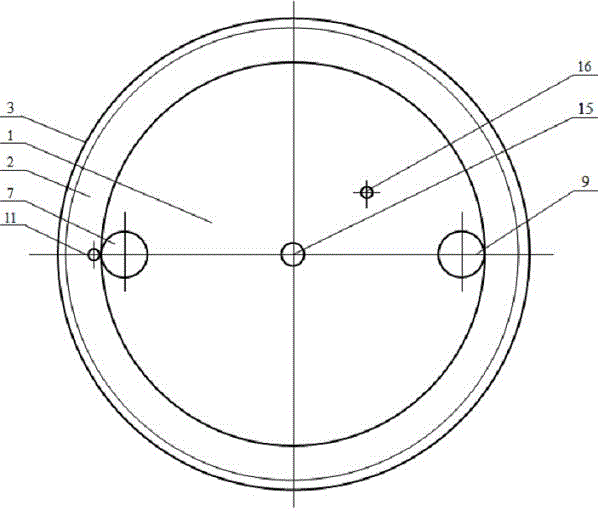

Low temperature anaerobic biogas fermentation tank

ActiveCN104031825BSolve the problem of incapable of anaerobic fermentationImprove insulation effectApparatus sterilizationGas production bioreactorsExternal energyThermal insulation

The invention relates to a low-temperature anaerobic biogas fermentation tank. The low-temperature anaerobic biogas fermentation tank comprises a tank body, and a gas storage chamber and a fermentation chamber which are arranged in the tank body. A feeding pipeline is arranged at one side in the tank body, and a discharging pipeline is arranged at the other side; the top of the tank body between the feeding pipeline and the discharging pipeline is provided with the gas storage chamber, the top of gas storage chamber is provided with a center hole and a gas outlet; a manual stirring device is arranged in the center hole, the tail end of the manual stirring device goes through the gas storage chamber and stretches into the fermentation chamber; a gas outlet pipeline is arranged in the gas outlet; an inoculation pipeline is arranged between the feeding pipeline and the inner wall of the tank body; the outer wall of the tank body is sequentially provided with a thermal insulation layer and a protective layer from inside to outside, a low temperature strain activation chamber is arranged between the fermentation chamber and the bottom of the tank body, and the low temperature strain activation chamber is connected with the inoculation pipeline; and a manual discharging pump is arranged in the discharging pipeline. The tank has the advantages of simple structure, convenient use, good sealing performance, good thermal insulation performance, long service life and the like, and can realize the normal biogas fermentation of the north in winter without an external energy supply.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

Good-toughness plastic particle based on production of automobile parts and preparation method thereof

The invention discloses a good-toughness plastic particle based on the production of automobile parts. Raw materials include (by weight): 70%-80% of a nylon material, 8%-12% of a toughening agent, 3%-7% of short glass fiber, 2%-5% of methyl phenyl vinyl silicone rubber, 2%-5% of cis-1,4-polybutadiene rubber, 2%-5% of a binder, 0.5%-1.5% of a toner and 0.5%-1.5% of a light stabilizer. The inventionrelates to the field of plastic processing technology. According to the good-toughness plastic particle based on the production of automobile parts and a preparation method thereof, the nylon material is used as a main material, short glass fiber is added to increase the strength, and methyl phenyl vinyl silicone rubber and cis-1,4-polybutadiene rubber are added to endow the product with excellent low temperature resistance. Meanwhile, cis-1,4-polybutadiene rubber endows the product with a certain elasticity. With the cooperation of the toughening agent, toughness of the plastic particle is greatly enhanced, and the plastic particle is not easy to crack. With the methyl phenyl vinyl silicone rubber combined with the light stabilizer, the plastic particle has excellent corrosion resistanceand ageing resistance and its service life is long.

Owner:宁波峻源复合材料科技有限公司

Acid-modified potash water glass-fluorocarbon-modified styrene-acrylic emulsion composite coating and preparation method thereof

ActiveCN105504904AReduce moisture absorptionImprove water resistanceAlkali metal silicate coatingsAnti-corrosive paintsEmulsionFluorocarbon

The invention discloses an acid-modified potash water glass-fluorocarbon-modified styrene-acrylic emulsion composite coating and a preparation method thereof. The composite coating comprises a matrix component, an assistant component and filler. The matrix component is prepared from, by weight, 20-30 parts of acid-modified potash water glass and 5-12 parts of fluorocarbon-modified styrene-acrylic emulsion. The acid-modified potash water glass is adopted, the moisture absorption of a matrix is effectively reduced, and the water resistance of the coating is improved; meanwhile, the fluorocarbon-modified styrene-acrylic emulsion has the advantages of being high in chemical corrosion resistance and artificial aging resistance and the like, and the overall use performance of the coating is greatly improved.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Friction-resistant and high-shear-resistant composite rubber material containing fluorine-terminated active hydroxyl groups

The invention relates to a friction-resistant and high-shear-resistant composite rubber material containing fluorine-containing terminal active hydroxyl groups, which belongs to the field of friction-resistant materials. The invention provides a friction-resistant high-shear-resistant composite rubber material, the raw materials of which include: 0.1-10 parts by weight of a fluorine-containing terminal active hydroxyl friction-resistant active surface modified resin, 50-90 parts by weight of semi-vulcanized rubber; the fluorine-containing terminal The structural formula of the radical active hydroxyl anti-friction active surface modification resin is shown in formula I, wherein, 0<m≤200, 0<n≤200, M is perfluorohexylsulfonyl, perfluorohexyl, perfluorohexylsulfonyl , perfluorooctylsulfonyl or perfluorooctanoyl. The invention prepares the semi-aromatic polyether amide with high-performance fluorine-containing end groups and active hydroxyl graft groups, and uses its excellent comprehensive performance to coat and compound the semi-aromatic polyetheramide with traditional rubber to improve the friction performance of rubber seals.

Owner:SICHUAN UNIV +1

Tension-resistant impact-resistant cable material for large power and preparation method thereof

InactiveCN105062075AImprove tensile propertiesHigh tear strengthRubber insulatorsElastomerPolyolefin

The invention discloses a tension-resistant impact-resistant cable material for large power. The tension-resistant impact-resistant cable material is prepared from 3-4 parts by weight of nanometer barium sulfate, 1-2 parts by weight of a promoter ZDC, 3-5 parts by weight of an acrylate copolymer elastomer, 4-6 parts by weight of a silane cross-linking agent, 20-30 parts by weight of broken waste and old cable, 35-55 parts by weight of silicone rubber, 3-5 parts by weight of sulphur, 2-4 parts by weight of a maleic anhydride-grafted polyolefin elastomer, 4-5 parts by weight of triallyl isocyanurate, 3-4 parts by weight of silicone oil, 3-4 parts by weight of diphenyl methane-4,4'-diisocyanate, 4-6 parts by weight of polyurethane, 2-4 parts by weight of potassium nitrate, 3-5 parts by weight of benzoyl peroxide and 8-12 parts by weight of a filler. The tension-resistant impact-resistant cable material has excellent tensile strength and tearing strength. Through use of polyurethane, impact resistance, hydrolysis resistance and oil resistance of the product are improved. The tension-resistant impact-resistant cable material is a novel cable material with a high economic value.

Owner:安徽电信器材贸易工业有限责任公司

Nontoxic and odorless cable material for large power and preparation method thereof

InactiveCN105017660AEasily biodegradableImprove mechanical propertiesPlastic/resin/waxes insulatorsLow-density polyethyleneAlkylphenol

The invention discloses a nontoxic and odorless cable material for large power. The nontoxic and odorless cable material is prepared from 3-5 parts by weight of paraffin, 2-4 parts by weight of high density polyethylene, 6-8 parts by weight of low density polyethylene, 12-18 parts by weight of high strength polypropylene resin, 2-3 parts by weight of stearic acid, 4-5 parts by weight of alkylphenol polyoxyethylene, 35-55 parts by weight of butyl rubber, 3-5 parts by weight of zinc borate, 2-4 parts by weight of antimonous oxide, 3-5 parts by weight of tris[2,4-di-tert-butylphenyl]phosphite, 4-6 parts by weight of dicumyl peroxide, 4-7 parts by weight of ethyl acrylate, 2-3 parts by weight of poly(diallyldimethylammonium chloride), 3-4 parts by weight of barium sulfate and 8-12 parts by weight of fillers. The nontoxic and odorless cable material utilizes nontoxic and odorless raw materials and is biodegradable easily. Through use of multiple fillers such as alkylphenol polyoxyethylene and poly(diallyldimethylammonium chloride), the nontoxic and odorless cable material has excellent mechanical properties and chemical resistance and is suitable for being used under multiple conditions.

Owner:ANHUI TELI SCI & TECH

Friction-resistant and high-shear composite rubber sealing material

ActiveCN113214524BImprove thermal performanceImprove machinabilityPolyether coatingsPolymer sciencePolyamide

The invention relates to a friction-resistant and high-shear-resistant composite rubber sealing material, which belongs to the field of friction-resistant materials. The invention provides a friction-resistant and high-shear-resistant composite rubber sealing material. The raw materials include: 0.1-10 parts by weight of a friction-resistant active surface-modified resin, 50-90 parts by weight of semi-vulcanized rubber; the structural formula of the friction-resistant active surface-modified resin As shown in formula I, wherein, 0<m≤200, 0<n≤200. The present invention introduces soft segments of different carbon chain lengths containing polyether amine into the molecular main chain of semi-aromatic polyamide plastics, thereby endowing traditional semi-aromatic polyether amide with excellent flexibility and stress deformation while maintaining excellent friction performance. Restoration: The present invention introduces active carboxyl groups into the main chain of polymer molecules through copolymerization, and greatly improves the interfacial bonding force between materials and rubber products through the effects of intermolecular hydrogen bonds and van der Waals forces, thereby overcoming traditional rubber-plastic composite materials. The problem of poor interface bonding force and shear resistance.

Owner:SICHUAN UNIV +1

Low-smoke zero-halogen cable material for high power and preparation method thereof

InactiveCN105001528AStrong mechanical propertiesImprove heat resistanceLinear low-density polyethyleneEngineering

The invention discloses a low-smoke zero-halogen cable material for high power. The low-smoke zero-halogen cable material comprises, by weight, 2-4 parts of chlorcosane, 6-8 parts of calcium carbonate, 3-4 parts of linear low-density polyethylene, 2-4 parts of melamine cyanurate, 2-3 parts of sulphur, 1-2 parts of accelerant, 3-5 parts of dioctadecyl 3,3'-thiodipropionate, 2-3 parts of boric acid, 2-4 parts of diisooctyl sebacate, 1-3 parts of dimethyltin bis(isooctylmercaptoacetate), 2-4 parts of triallyl isocyanurate, 4-5 parts of low-molecular PE wax, 40-60 parts of ethylene propylene diene monomer, 2-5 parts of trimellitate and 8-12 parts of filling agent. The low-smoke zero-halogen cable material has the excellent mechanical performance, heat resistance and weather resistance, the added triallyl isocyanurate can remarkably shorten the vulcanizing time, and production cost is reduced.

Owner:安徽电信器材贸易工业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com