High-strength composite elastic energy-absorption anti-collision device and production method thereof

A technology of anti-collision devices and production methods, which can be applied to other household appliances, climate change adaptation, household components, etc., can solve the problems of damage to the hull, strong rigidity, and short service life, and achieve excellent anti-corrosion and aging resistance and large compression deformation , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

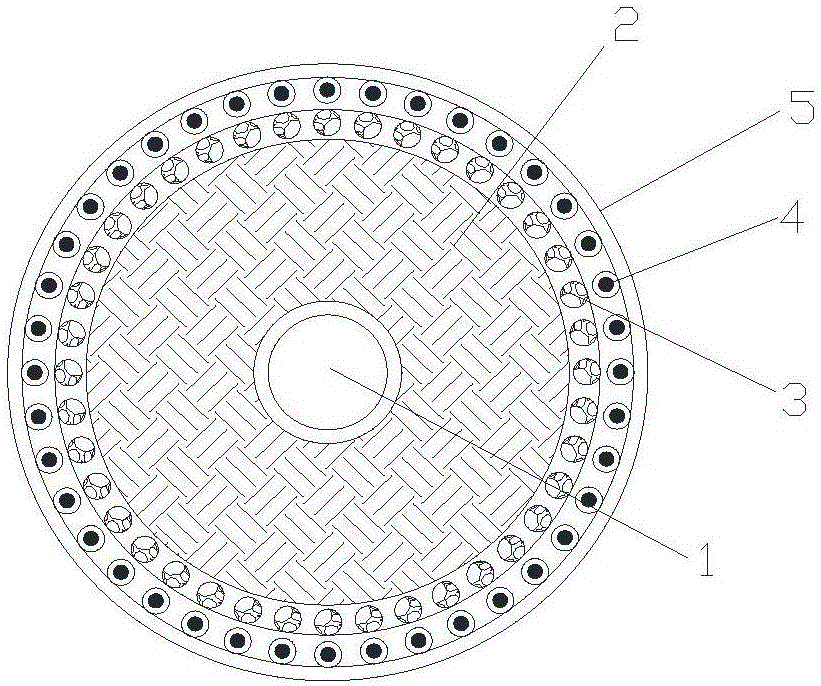

[0023] Production method of high-strength composite elastic energy-absorbing anti-collision device,

[0024] In the first step, the polymer closed-cell foam material is made into a mold (such as a cylindrical shape), and steel pipes with a size of 79mm, 140mm, and 170mm are placed in the middle as a reinforced structure. The overall size is made into diameters of 300mm, 500mm, and 1000mm, 1500mm, 2000mm;

[0025] The second step is to use a rotary casting machine to cast in 3D without a mold, and first cast the bottom layer of high-strength fibers with a 3D flat nozzle, with a thickness of 3mm;

[0026] Step 3: Use a rotary casting machine to pour in 3D without mold, and then pour the composite fiber strength layer with a 3D round nozzle, and the pouring thickness is 2mm;

[0027] Step 4: Finally, manually cast SPUA surface coating (SPUA is sprayed polyurea elastomer, sprayed polyurea elastomer is a new type of solvent-free, pollution-free green construction technology); the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com