Method for producing wood plastic composite pipes and pipe fittings

A production method and wood-plastic composite technology, applied in the direction of pipes/pipe joints/fittings, chemical instruments and methods, synthetic resin layered products, etc., can solve problems such as corrosion and peeling off of the cortex, pollution of the production environment, and difficulty in connecting pipe fittings, etc., to achieve Stable product quality, high strength, simple and reliable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

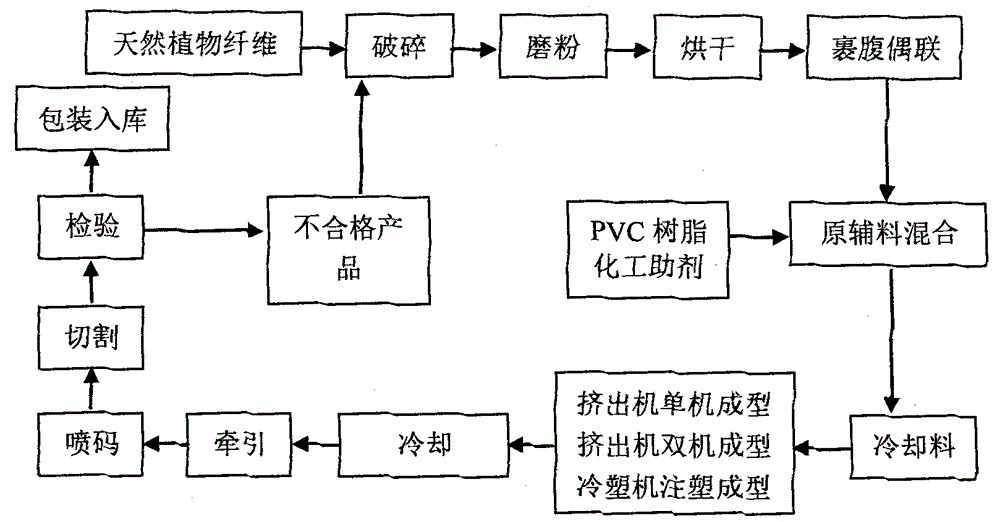

[0014] The following is attached figure 1 , further describe the production process and method of wood-plastic composite pipes and pipe fittings provided by the present invention: firstly, the plant fibers are crushed and ground into 200-300 meshes, and then dried; The bonding temperature is 50℃~60℃; then add 100 parts of PVC resin, 20 parts of filler calcium carbonate, 4 parts of TK-238 composite lead stabilizer, 3 parts of 135A chlorinated polyethylene, 0.2 parts of 60# paraffin, stearic acid 0.3 part, 0.4 part of lead stearate, 1 part of sodium bicarbonate, 0.8 part of azodicarbonamide foaming agent, 4 parts of acrylate modifier, the mixture after the above ratio is mixed is put into the mixer, and in High-speed hot mixing at a speed of 2400 rpm, the hot mixing temperature is 100°C to 110°C; the cooled ingredients are put into a cold mixer for cold mixing, and the cold mixing temperature is 40°C to 50°C; finally, the cold mixed ingredi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com