High-temperature-resistant CPVC plastic wood composite material

A wood-plastic composite material, high-temperature-resistant technology, applied in the field of composite wood boards, can solve problems such as shrinkage, board warping, deformation, etc., and achieve high-temperature resistance, increased deformation temperature, and excellent aging and corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

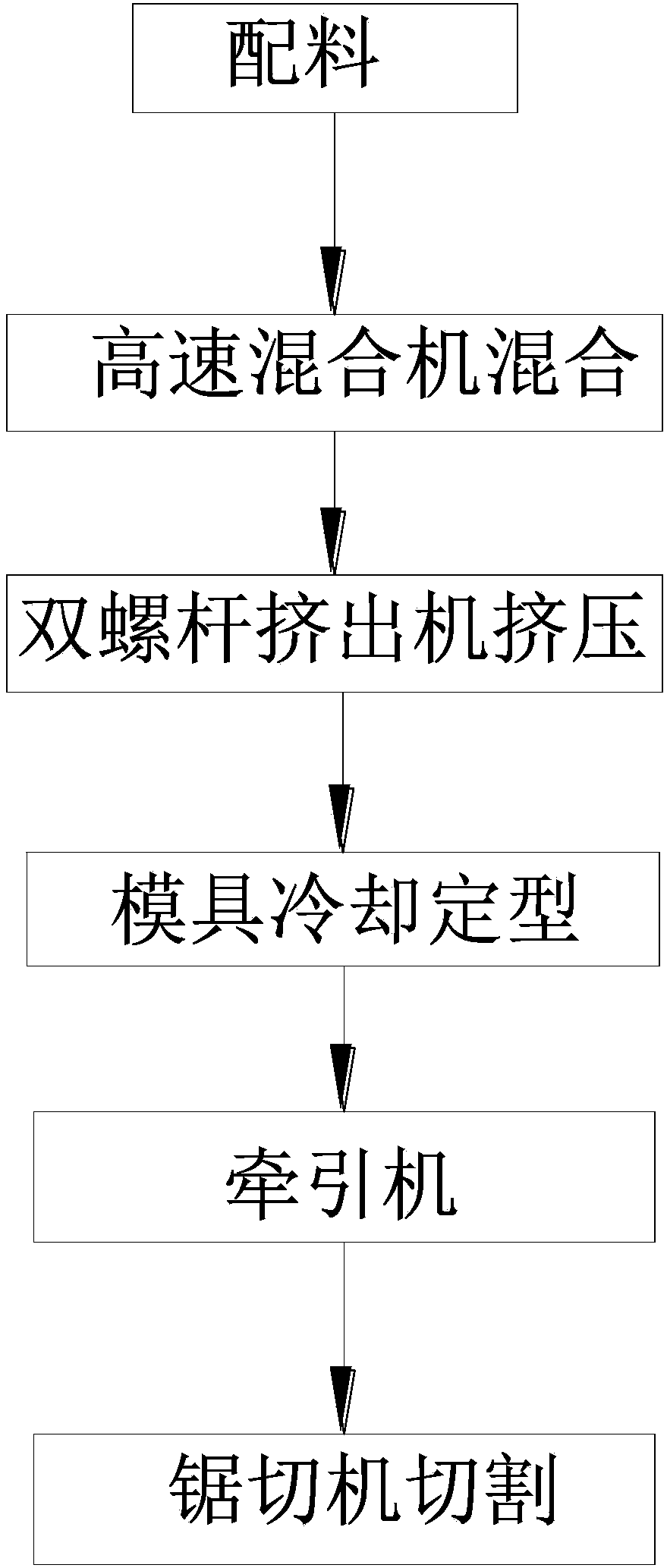

[0013] as attached figure 1 As shown, the present invention provides a high temperature resistant CPVC plastic wood composite material, which is prepared from the following components in weight percentage: 30% CPVC resin, 20% PVCSG-8 resin, 20% bamboo wood fiber powder, 10% % light active calcium carbonate inorganic filler, 10% modifier, 5% processing aid, mix the ingredients of the above components uniformly with a high-speed mixer, and the mixing time is 1-2h, and then the twin-screw extruder will mix the The ingredients are extruded, and the twin-screw extruder is used to cool and shape the mold. After being processed by the tractor, the composite wood boards of different lengths and specifications are cut by the board cutting machine. The head temperature of the twin-screw extruder is 176°C, the water temperature for cooling and shaping the mold is 18°C, and the extrusion temperature of the twin-screw extruder is 165-178°C. The high-temperature-resistant type of wood-plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com