Acid-modified potassium silicate-fluorocarbon modified styrene-acrylic emulsion composite coating and preparation method thereof

A technology of potassium silicate and styrene-acrylic emulsion, which is applied in the direction of alkali metal silicate coatings, anti-corrosion coatings, coatings, etc., can solve the problems of reduced water resistance of colloids, unsatisfactory corrosion resistance, etc., to reduce moisture absorption, The effect of improving the overall performance and increasing the water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

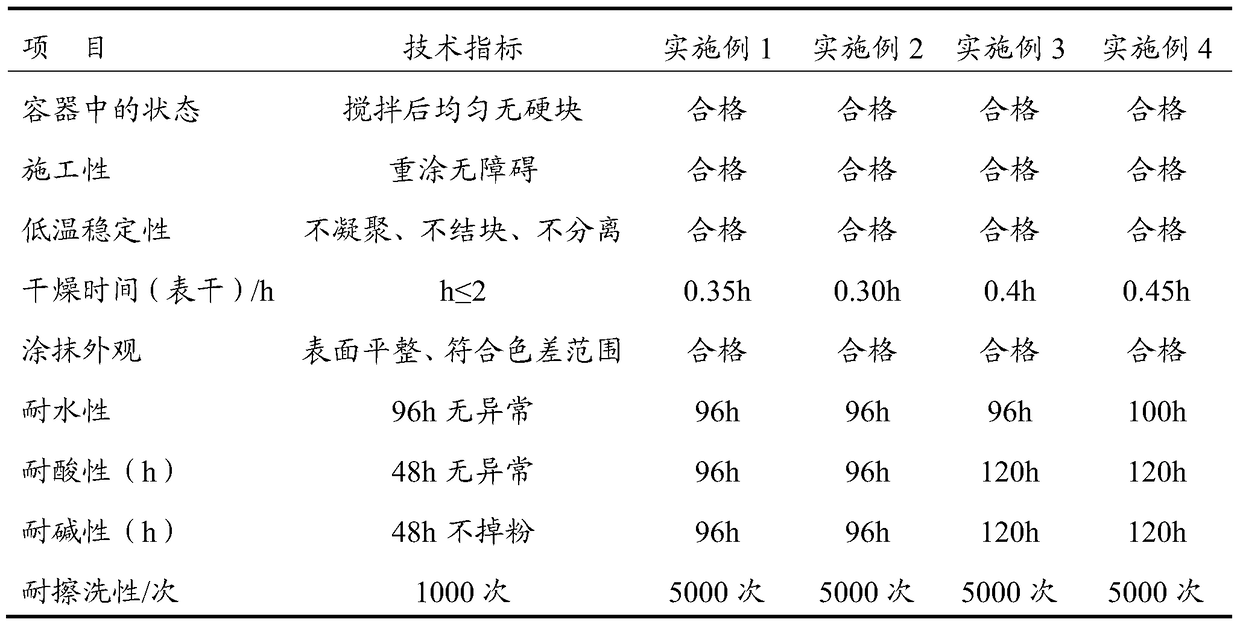

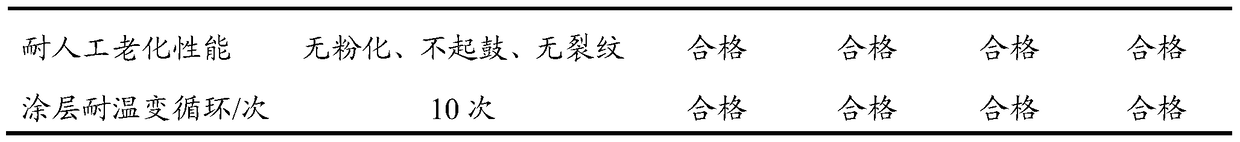

Examples

Embodiment 1

[0038] Embodiment 1 (for the exterior wall of the acid volatilization workshop)

[0039] Preparation of acid-modified potassium silicate: Weigh 76% of the modulus ratio as SiO 2 / K 2 O=4, concentration is 30% potassium water glass, put potassium water glass into the dispersing and stirring equipment, under 1300rpm high-speed stirring, slowly add 0.6% stabilizer tin mercaptide and pure water, stir evenly, Then add 1% hydrochloric acid to adjust the pH value of the potassium water glass to 11 to obtain acid-modified potassium water glass. Weigh 22 parts of acid-modified potassium water glass for use.

[0040] Preparation of fluorocarbon modified styrene-acrylic emulsion: Add 60% BC-01 styrene-acrylic emulsion into a four-necked bottle, stir at 300rpm, raise the temperature to 75°C, slowly add 8% fluorocarbon emulsion dropwise, and slowly Slowly add 0.9% aminoethylaminopropyl polydimethylsiloxane, then add 0.8% octylphenol polyoxyethylene ether, 0.01% polyether modified polys...

Embodiment 2

[0043] Embodiment 2 (for the exterior wall of the acid volatilization workshop)

[0044] Preparation of acid-modified potassium silicate: Weigh 78% of the modulus ratio as SiO 2 / K 2 O=4, concentration is 30% potassium water glass, potassium water glass is put into dispersion mixing equipment, under 1300rpm high-speed stirring, slowly add 0.7% stabilizer tin mercaptide and pure water, stir evenly, Then add 1.1% hydrochloric acid to adjust the pH of the potassium water glass to 11 to obtain acid-modified potassium water glass. Weigh 20 parts of acid-modified potassium water glass for use.

[0045] Preparation of fluorocarbon modified styrene-acrylic emulsion: Add 60% BC-01 styrene-acrylic emulsion into a four-necked bottle, stir at 400rpm, raise the temperature to 74°C, slowly add 7.5% fluorocarbon emulsion dropwise, and slowly Slowly add 0.8% aminoethylaminopropyl polydimethylsiloxane, then add 0.8% octylphenol polyoxyethylene ether, 0.01% polyether modified polysiloxane ...

Embodiment 3

[0048] Embodiment 3 (for the interior wall of the acid volatilization workshop)

[0049] Preparation of acid-modified potassium silicate: Weigh 80% of the modulus ratio as SiO 2 / K 2 O=4, concentration is 30% potassium water glass, put potassium water glass into the dispersing and stirring equipment, under 1500rpm high-speed stirring, slowly add 0.9% stabilizer tin mercaptide and pure water, stir evenly, Then add 1.2% hydrochloric acid to adjust the pH value of the potassium water glass to 11 to obtain acid-modified potassium water glass. Weigh 25 parts of acid-modified potassium water glass for use.

[0050] Preparation of fluorocarbon modified styrene-acrylic emulsion: Add 70% BC-01 styrene-acrylic emulsion into a four-necked bottle, stir at 400rpm, raise the temperature to 76°C, slowly add 9% fluorocarbon emulsion dropwise, and slowly Slowly add 1% aminoethylaminopropyl polydimethylsiloxane, then add 1% octylphenol polyoxyethylene ether, 0.02% polyether modified polysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com