Friction-resistant and high-shear composite rubber sealing material

A compound rubber and sealing material technology, applied in the field of friction-resistant materials, can solve the problems such as reports of friction-resistant and high-shear-resistant compound rubber sealing materials that have not been found, and achieve overcoming interface bonding force, low friction coefficient and wear and tear, and excellent friction resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] (1) Preparation and purification of dihalogenated monomers containing different soft segment lengths:

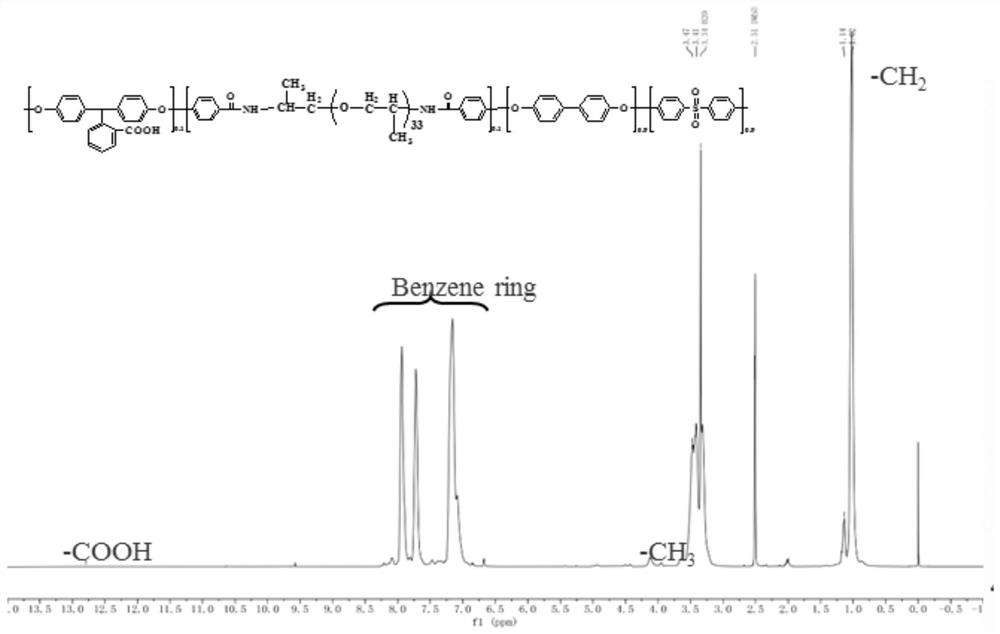

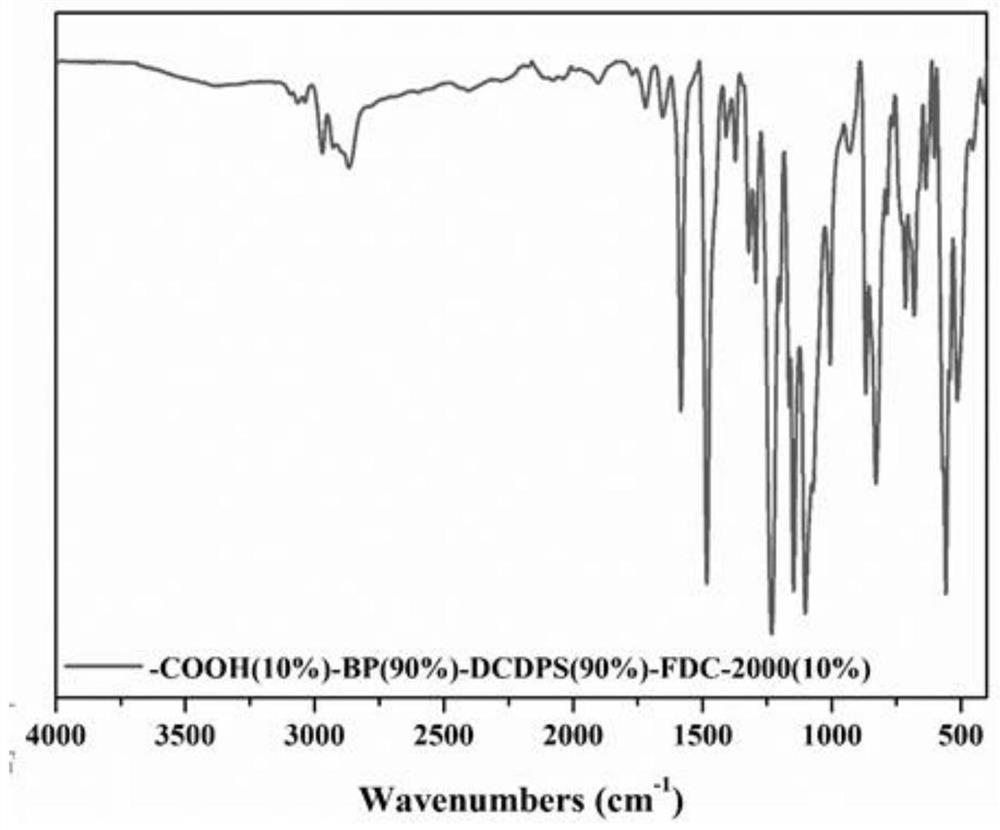

[0073] Add 2000 g of ether-containing diamine containing 33 alkyl carbons, 80 g of sodium hydroxide, and 3 g of sodium dodecyl benzene sulfonate to 5,000 g of deionized water in turn, and dissolve at room temperature to obtain ether-containing diamine solution; 317g of fluorobenzoyl chloride and 5000g of dichloromethane were mixed evenly and added to the container, and then the ether-containing diamine solution prepared above was added dropwise into the container. After the diamine solution was added dropwise, the reaction was continued at room temperature for 5h , to generate 33 alkylcarbodiamide difluorinated monomers; the organic solvent in the above monomers was distilled and recovered, the viscous crude product was collected, washed with water 4 times, removed the solvent, and dried at 110 °C for 6 h to obtain a purified 33 alkylcarbodiamide difluoro monomers, th...

Embodiment 2

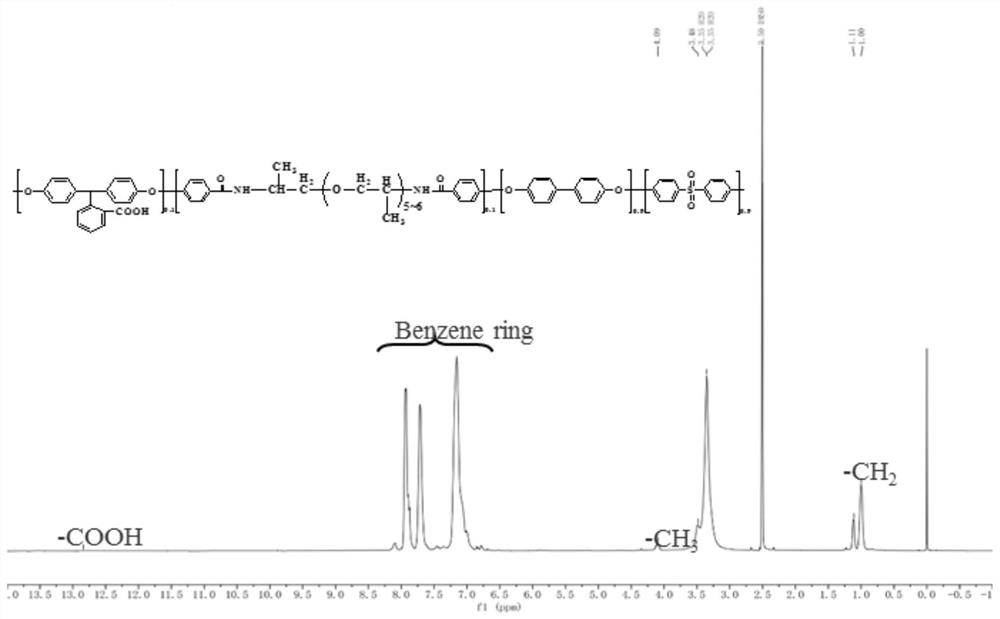

[0083] (1) Preparation and purification of dihalogenated monomers containing different soft segment lengths:

[0084] Add 400 g of ether-containing diamine containing 5 alkyl carbons, 90 g of lithium hydroxide, and 10 g of PEG-1000 to 4000 g of deionized water successively, and dissolve at room temperature to obtain ether-containing diamine solution; 317 g of p-fluorobenzoyl chloride Mix it with 4000g of chloroform and add it to the container, then add the ether-containing diamine solution prepared above dropwise into the container. After the diamine solution is added dropwise, continue to react at room temperature for 3h to generate 5 alkyl groups. Carbodiamide difluorinated monomer; the organic solvent in the above monomer is recovered by distillation, the viscous crude product is collected, washed with water for 4 times, the solvent is removed, and dried at 100°C for 24h to obtain a purified carbodiamide containing 5 alkyl groups Difluoro monomer, the structural formula is ...

Embodiment 3

[0094] (1) Preparation and purification of dihalogenated monomers containing different soft segment lengths:

[0095] 230 g of ether-containing diamine containing 2 alkyl carbons, 100 g of triethylamine, and 20 g of Tween 80 were successively added to 4,500 g of deionized water, and dissolved at room temperature to obtain ether-containing diamine solution; p-chlorobenzoyl chloride 348 g Mix it with 3500g of chlorobenzene and add it to the container. Then add the ether-containing diamine solution prepared above dropwise into the container. After the diamine solution is added dropwise, continue to react for 5h at room temperature to generate 2 alkanes. carbodiamide dihalogenated monomer; the organic solvent in the above monomer is recovered by distillation, the viscous crude product is collected, washed with water for 4 times, the solvent is removed, and dried at 100°C for 12h to obtain a purified product containing 2 alkyl carbodiamides. Amide dichlorinated monomer, the structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wear volume | aaaaa | aaaaa |

| wear volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com