Corrosion-resistant printed circuit board and its preparation method

A printed circuit board, corrosion-resistant technology, applied in the direction of printed circuit components, electrical connection printed components, printed components electrical connection formation, etc., to achieve good corrosion resistance and aging resistance, guaranteed pass rate, and improved corrosion resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The resin used in the embodiment of the present invention is epoxy resin, purchased from Sanei Chemical Co., Ltd.

[0032] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

[0033] A method for preparing a corrosion-resistant printed circuit board, the printed circuit board includes a gold finger area and a circuit area, and the preparation method includes the following steps:

[0034] (1) Whole board electroplating: The printed circuit board after the previous process is electroplated to make the copper thickness reach 20-75mm (according to the customer's design requirements);

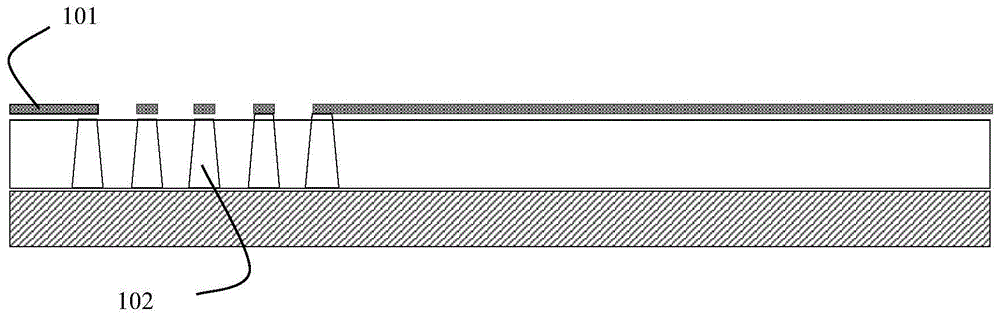

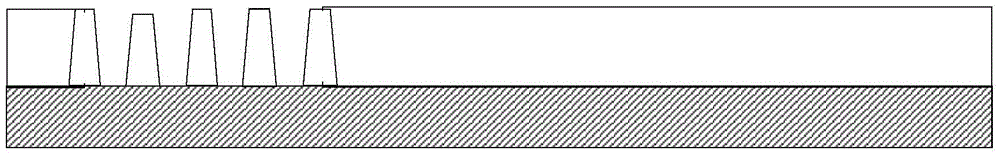

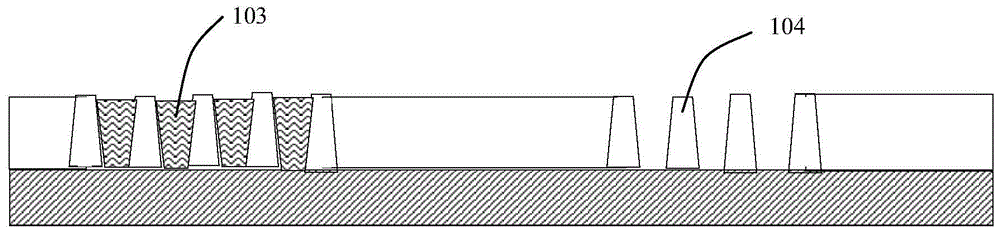

[0035] (2) Gold finger area production (refer to Figure 1-Figure 2 ):

[0036] ① Apply dry film 101, exposure and development, and etching to the printed circuit board obtained in step (1), and remove the copper between the gold fingers;

[0037] ②Fill epoxy resin 103 between the gold fingers, and grind the plate; first, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com