Manufacturing and mounting device and mounting method for super-long inclined steel frame column

A technology for installing devices and steel frames, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of inability to extend, inability to adjust angles, etc., and achieve the effect of fast extension installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

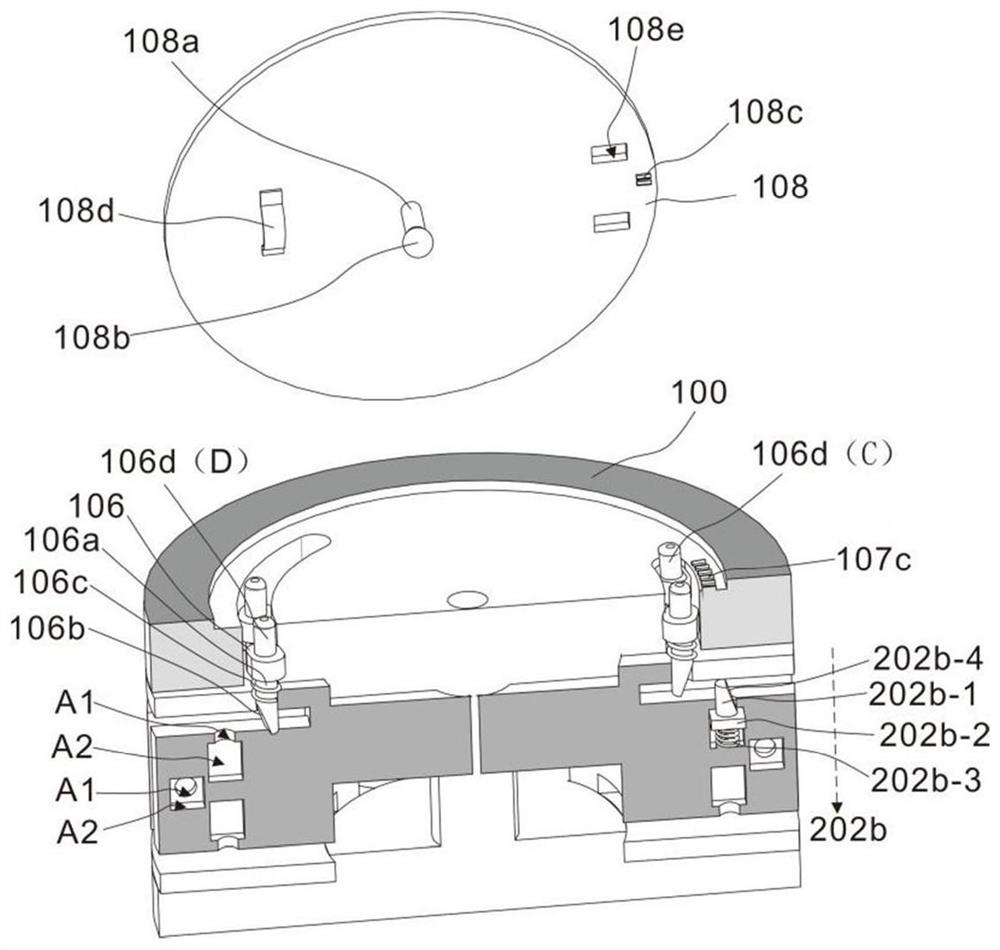

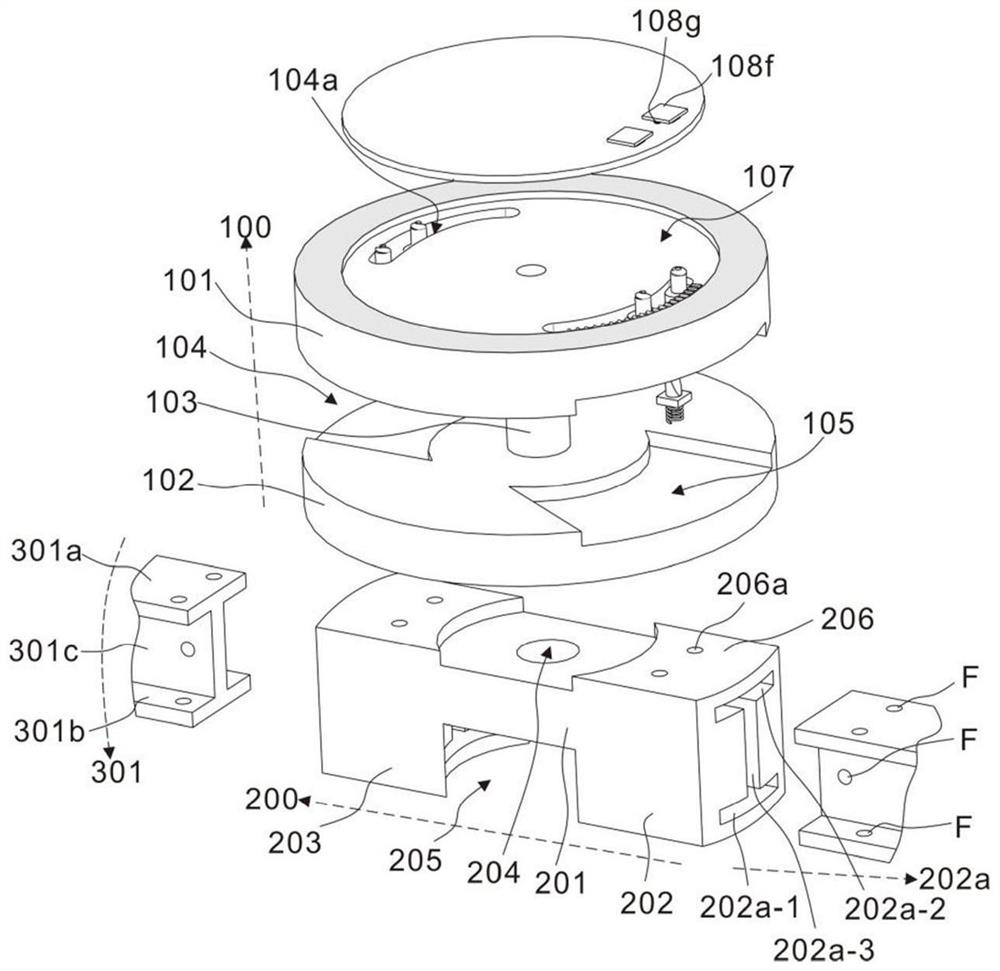

[0047] Reference Figure 1 、 2 , 4 and 5, the present embodiment provides an ultra-long oblique steel frame column production mounting device, comprising, a fixed disc 100, a fixed disc 100 comprising a first side disc 101, a second side disc 102 and an intermediate column connecting the first side disc 101, the second side disc 102 103, the first side disc 101 and the second side disc 102 is also provided with an intermediate slot 104, the first side disc 101 and the second side disc 102 are correspondingly provided with a fan-shaped slot 105; The adjustment frame 200 includes a coordination plate 201 and a first connection block 202 and a second connection block 203 are disposed at both ends of the coordination plate 201, the first connection block 202 and the second connection block 203 are located on the same side of the coordination plate 201, the first connection block 202 and the second connection block 203 is left with a circular groove 205, the coordination plate 201 is pr...

Embodiment 2

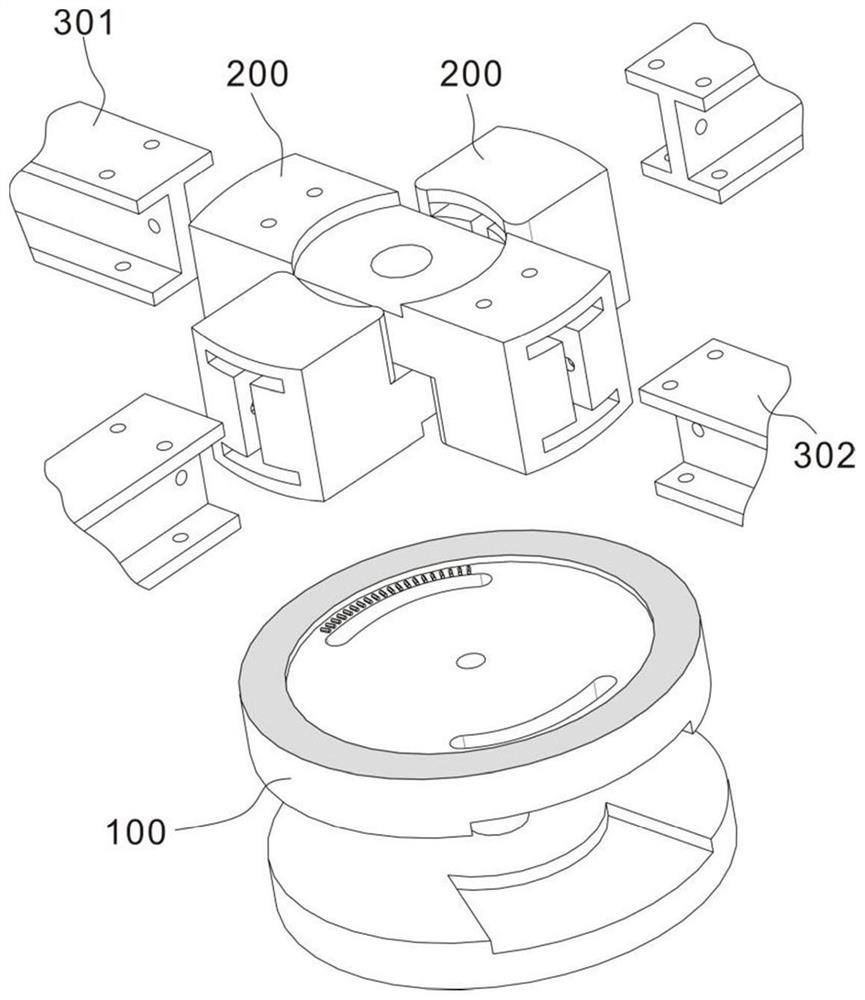

[0073] Reference Figures 1 to 6 , the present embodiment and the previous embodiment of the different residence is that, in the present embodiment, further comprises two pairs of oblique rod groups, each pair of inclined rod groups comprising the first inclined rod 301 and the second inclined rod 302, the first inclined rod 301 and the second inclined rod 302 of the same structure, the first inclined rod 301 includes the first horizontal plate 301a, the second horizontal plate 301b and the vertical plate 301c, the first horizontal plate 301a and the second horizontal plate 301b are compatible with the first horizontal groove 202a-1 and the second horizontal groove 202a-2 size, I.e., the first horizontal plate 301a and the second horizontal plate 301b may be embedded in the first horizontal slot 202a-1 and the second horizontal slot 202a-2, similarly, the vertical plate 301c and the vertical slot 202a-3 size match.

[0074] It should be noted that the first horizontal plate 301a, t...

Embodiment 3

[0077] The present embodiment provides an installation method for making a mounting device of an ultra-long oblique steel frame column, the first step, cutting the first incline rod 301 and the second incline rod 302 end to the slope is suitable, specifically according to the actual installation needs, calculate the incline angle at the bevel end E, the slope end E is required to be fixed with the bracket 400 welding or other ways to strengthen the overall strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com