Self-adaptive stress tunnel primary support steel support structure and construction method thereof

A steel-supported, self-adaptive technology, applied in tunnels, earthwork drilling, tunnel lining, etc., can solve problems such as damage, tunnel support damage, and passive force bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

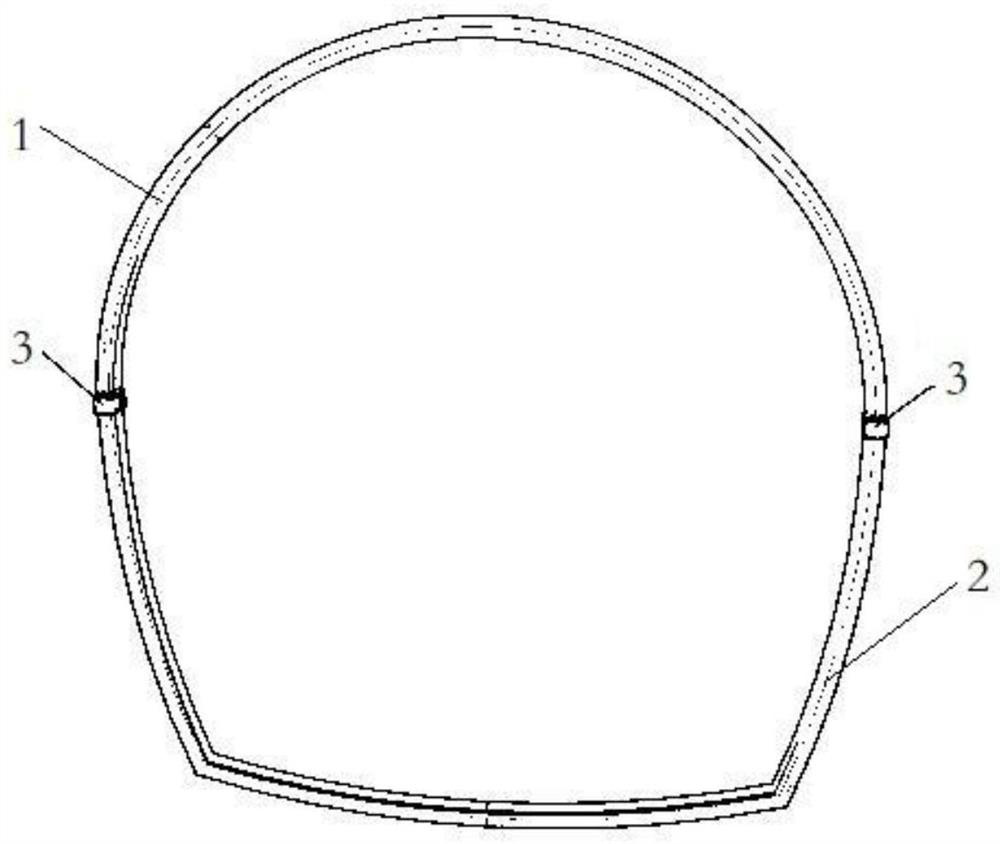

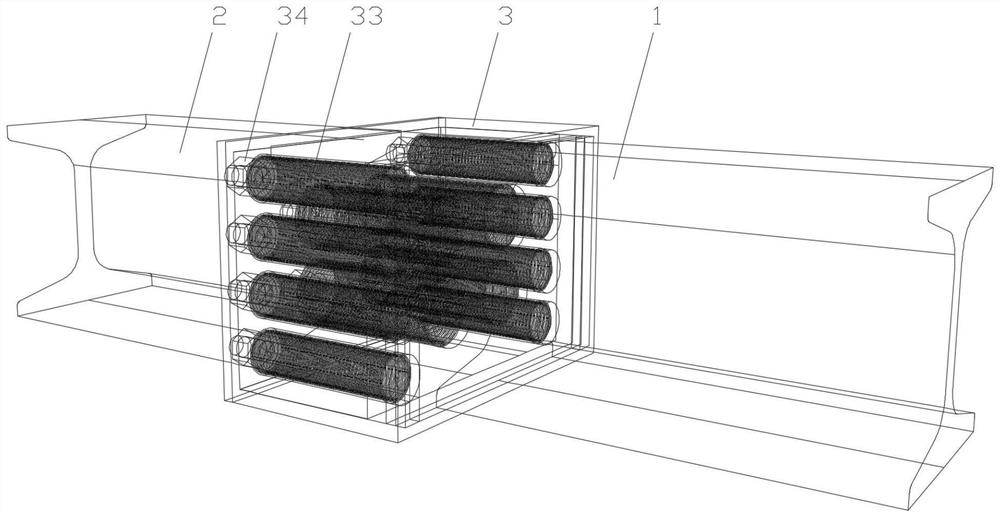

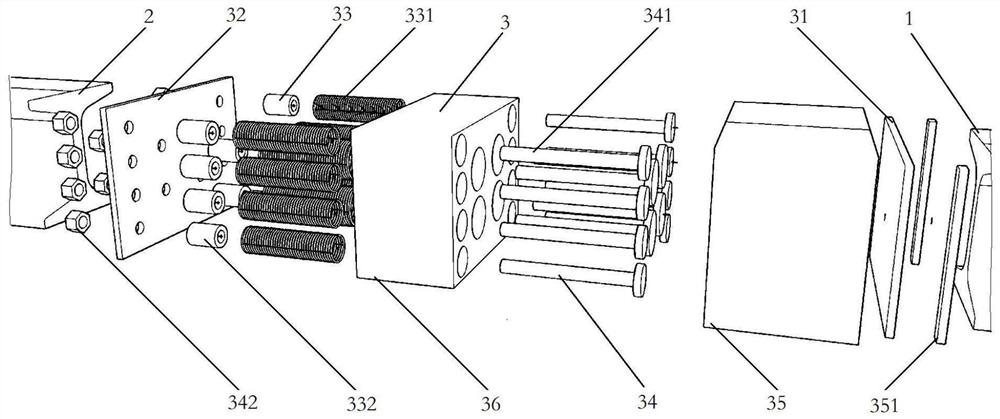

[0030] like figure 1 and figure 2 As shown in the figure, in the tunnel primary support steel support structure of the adaptive stress of this embodiment, the steel support is divided into two sections by the openings located at the side walls on both sides, which are the arch part 1 located at the upper part and the support part 2 located at the lower part. , each opening of the steel support is provided with a connecting device 3 connected between the arch part 1 and the support part 2, and the connecting device 3 elastically supports the arch part 1 and the support part 2 along the direction of the steel support sidewall part. , so that the overall steel support will have a vertical movement allowance, and the direction of this movement allowance is exactly the same as the deformation direction of the tunnel due to gravity.

[0031] When designing the steel support, even if the design section is inconsistent with the actual excavation end face structure, the steel support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com