Bearing assembly and air conditioner

A technology of bearing components and bearings, which is applied to bearing components, rigid supports of bearing components, air-conditioning systems, etc., can solve problems such as troubles and affect the efficiency of disassembly and assembly, and achieve the goal of ensuring the fixing effect, improving the fixing effect, and improving the disassembly and assembly efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

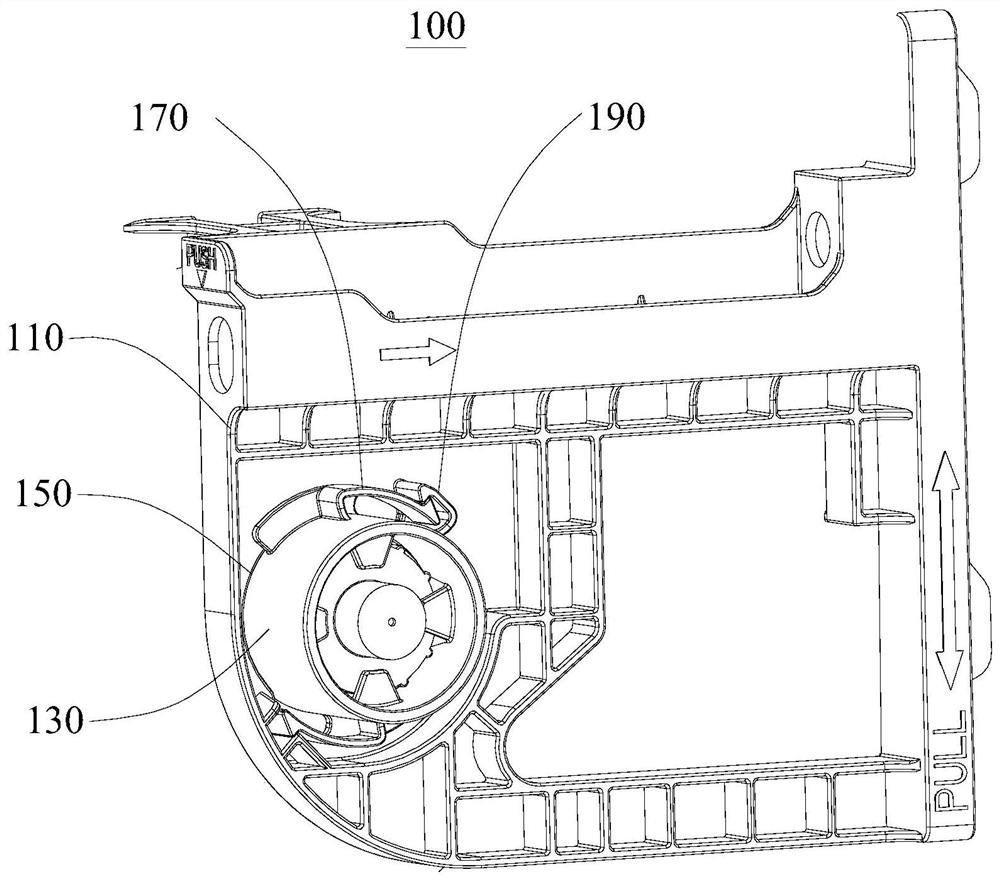

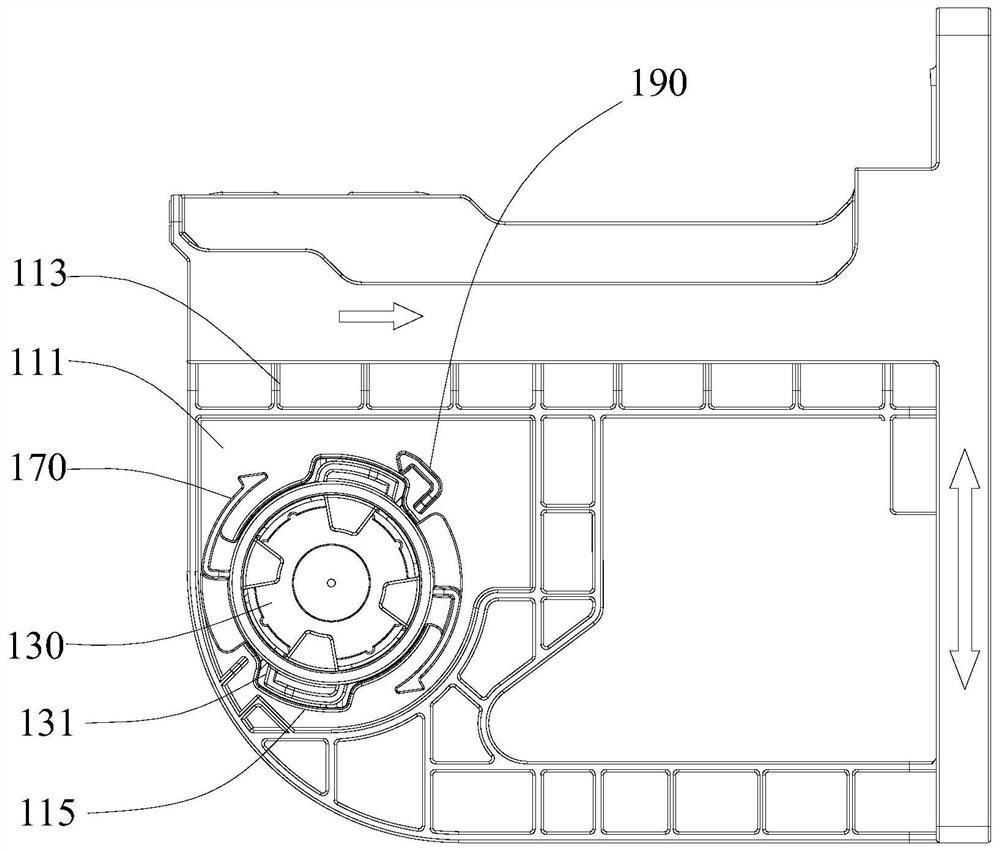

[0040] see in combination Figure 1 to Figure 6 , This embodiment provides a bearing assembly 100 , which is very convenient for disassembly and assembly, improves disassembly and assembly efficiency, and facilitates after-sales installation and maintenance of the complete machine.

[0041] The bearing assembly 100 provided in this embodiment includes a bearing bracket 110 and a mounting bearing 130 , the bearing bracket 110 is provided with a mounting through hole 150 , the mounting bearing 130 is rotatably assembled on the mounting through hole 150 , and the mounting bearing 130 is provided with a rotating clip The bearing bracket 110 is provided with a rotary hook 190, and the rotary hook 170 can rotate with the installation bearing 130 to hold the rotary hook 190 and lock the installation bearing 130 in the installation through hole 150, or to disengage the rotary hook hook 190 and unlock the mounting bearing 130 from the mounting through hole 150 .

[0042] In this embod...

no. 2 example

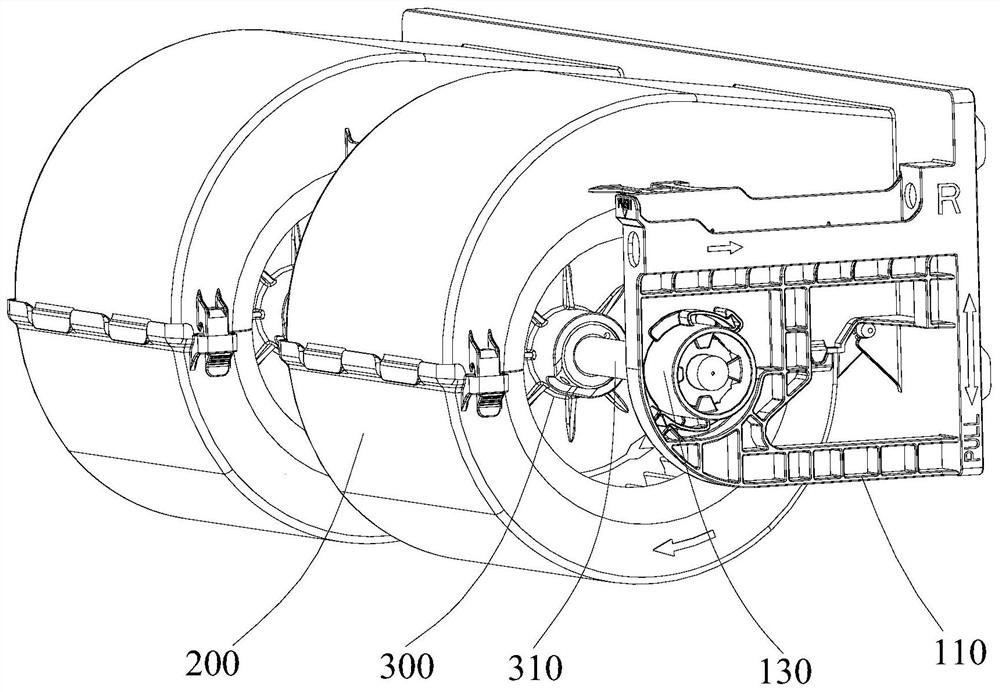

[0063] This embodiment provides an air conditioner, including a volute structure 200, a wind wheel assembly 300 and a bearing assembly 100, wherein the basic structure, principle and technical effect of the bearing assembly 100 are the same as those in the first embodiment. For brief description, For parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0064] The air conditioner provided in this embodiment includes a volute structure 200, a wind wheel assembly 300, and a bearing assembly 100. The bearing assembly 100 includes a bearing bracket 110 and a mounting bearing 130. The bearing bracket 110 is provided with a mounting through hole 150, and the mounting bearing 130 is rotatably assembled. The installation through hole 150 and the installation bearing 130 are provided with a rotary hook 170 , and the bearing bracket 110 is provided with a rotary hook 190 . The rotary hook 170 can rotate with the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com