Ultrasonic phased array high-efficiency phase shift imaging method for multilayer structure hole defects

An ultrasonic phased array, multi-layer structure technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and processing response signals of detection, etc. It can solve problems such as low efficiency and achieve The effect of high imaging resolution, improving imaging efficiency, and shortening computing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

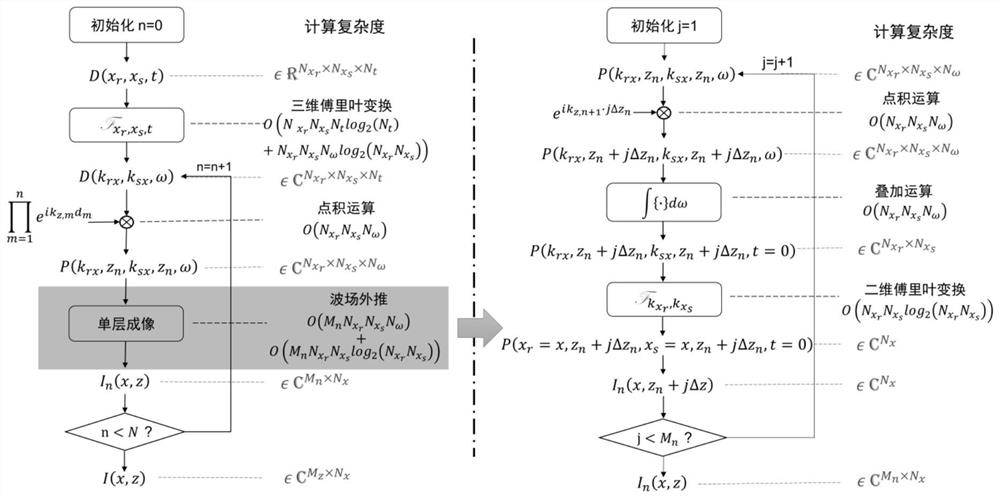

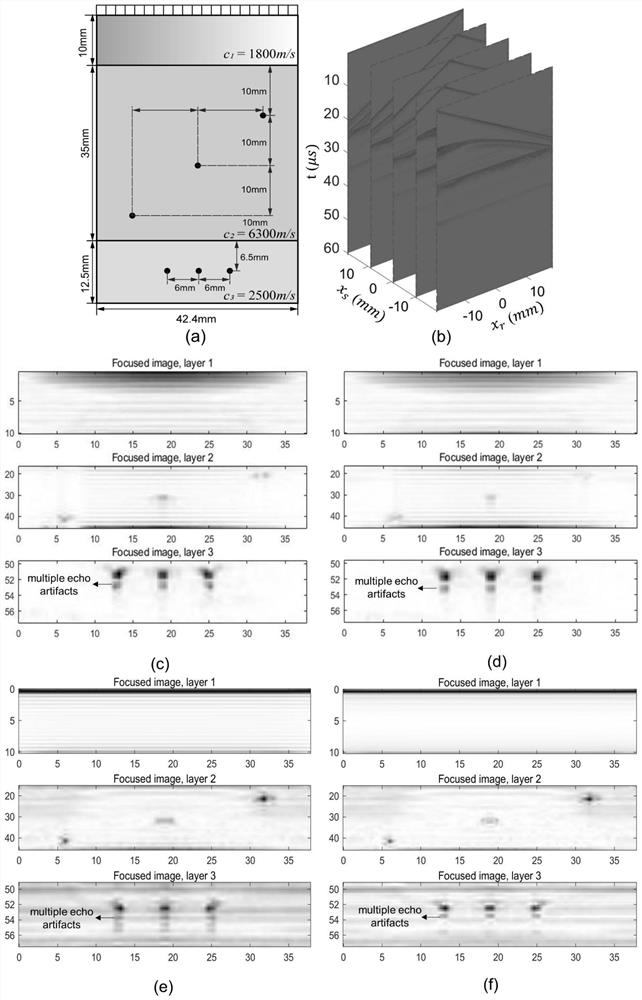

[0041] An ultrasonic phased array high-efficiency phase-shift imaging method for hole defects in a multilayer structure, comprising the following steps:

[0042] (1) Convert the full-matrix data of the multi-layer structure with hole defects into the frequency wavenumber domain through three-dimensional fast Fourier transform;

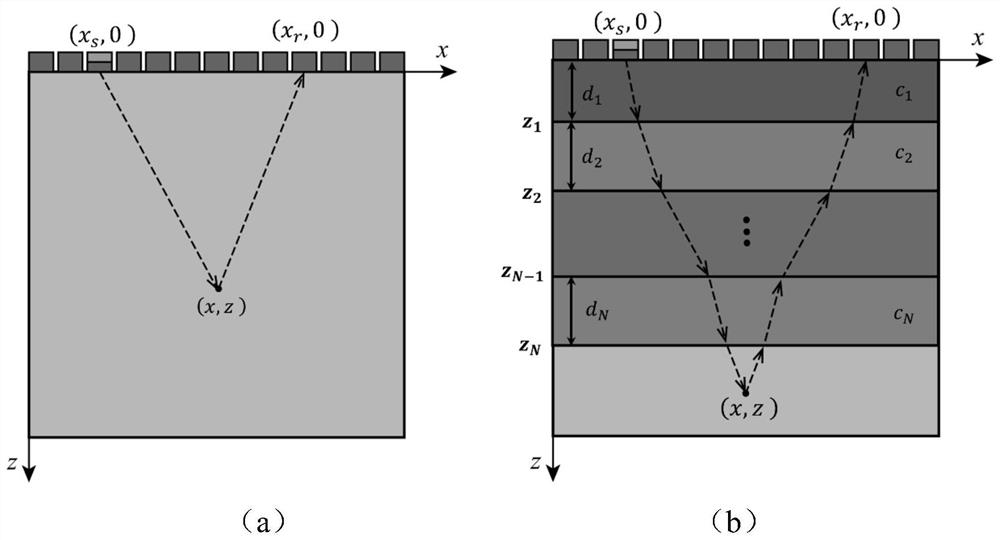

[0043] (2) For any non-traversed layer in the multi-layer structure, the surface wave field of the multi-layer structure is extrapolated downward to the upper interface of the non-traversed layer by using the double square root vertical wave number, and the wave field information of the non-traversed layer is obtained. ;

[0044] (3) According to the obtained wavefield information, in the frequency wavenumber domain, take t=0 as the imaging condition to perform focused imaging on the non-traversed layer;

[0045] The expression with time t=0 as the imaging condition is as follows:

[0046]

[0047] where k rx is the horizontal wave number of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com