Cable defect detection system and method based on pulse sine wave

A defect detection, sine wave technology, applied in information technology support systems, using optical methods to test, measure electricity, etc., can solve the problems of small changes in reflected signal amplitude, inability to detect small defects, change impedance, etc., to improve the signal The effect of detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment, the present invention is described in further detail:

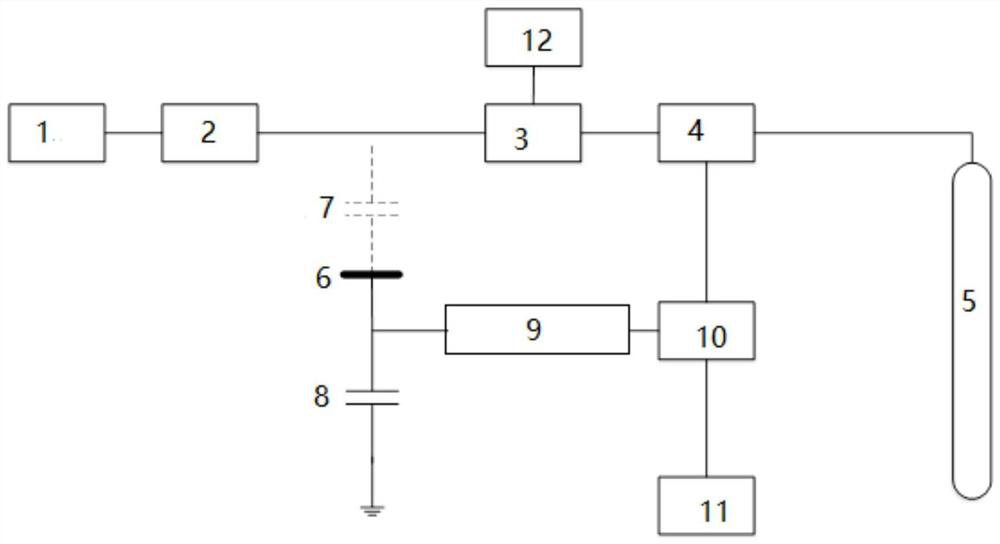

[0029] like figure 1 As shown, a cable defect detection system based on pulsed sine wave includes a sine wave generator 1 with a fixed frequency, and the output end of the sine wave generator 1 is connected to a high frequency voltage amplifier 2 to amplify the signal to several tens of kilovolts. The output end of the high-frequency voltage amplifier 2 is connected to the high-frequency switch 3, the output end of the high-frequency switch 3 is respectively connected to the coupler 4 and the controller 12, and the output end of the coupler 4 is respectively connected to the high-voltage cable 5 and the controller 12 to be detected. Three-way connector 10, a bare wire is formed between the high-frequency voltage amplifier 2 and the high-frequency switch 3, a space stray capacitance 7 is formed between the plate electrode 6 and the bare wire, and the plate electrode 6 is respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com