High-voltage power cable single-phase sheath double-end direct grounding method and system

A technology of high-voltage power and grounding method, which is applied in the direction of power cables, power cables for overhead applications, and information technology support systems, etc., and can solve problems such as hidden dangers of cable safe operation, reactor explosion, and large value of sheath circulation. Reduce the cost of engineering construction and, reduce the use, reduce the effect of induced voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The present application will be further described below with reference to the accompanying drawings. The following examples are only used to more clearly illustrate the technical solutions of the present invention, and cannot be used to limit the protection scope of the present application.

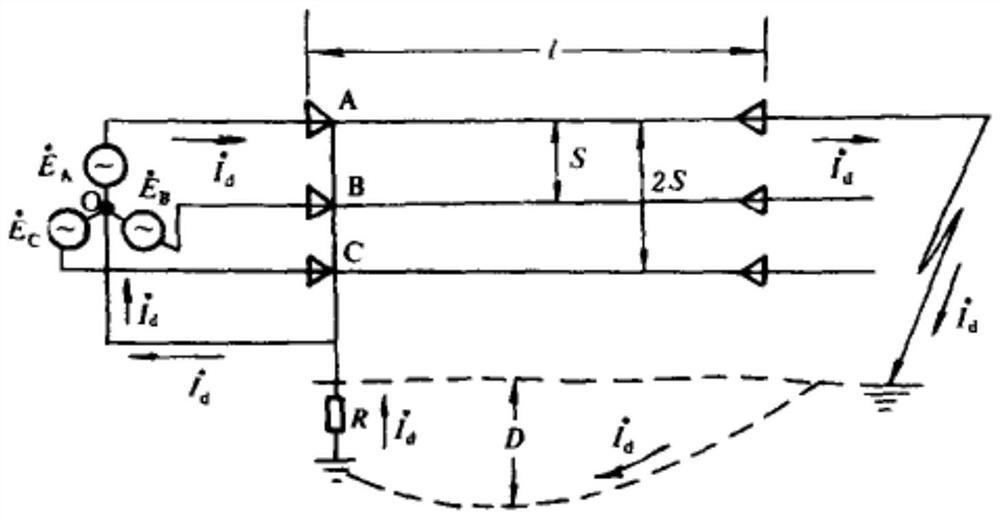

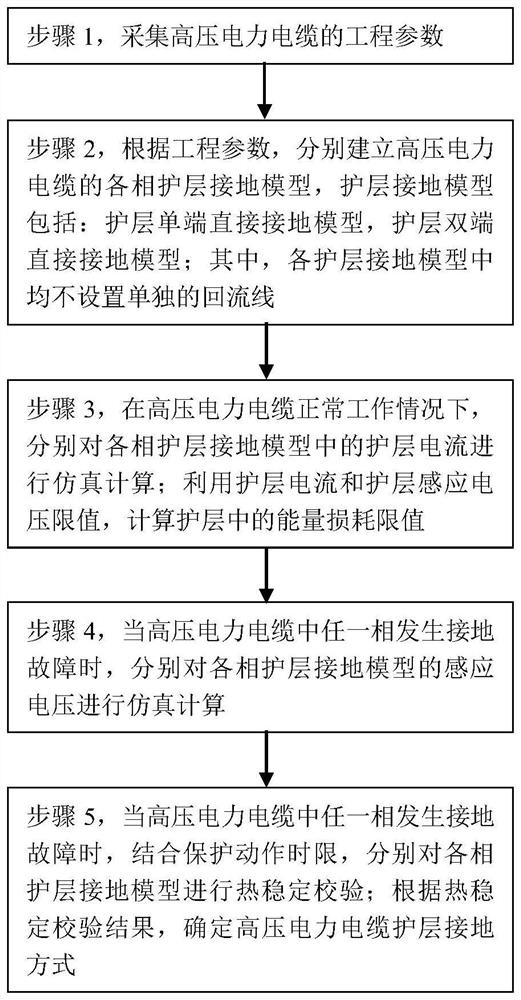

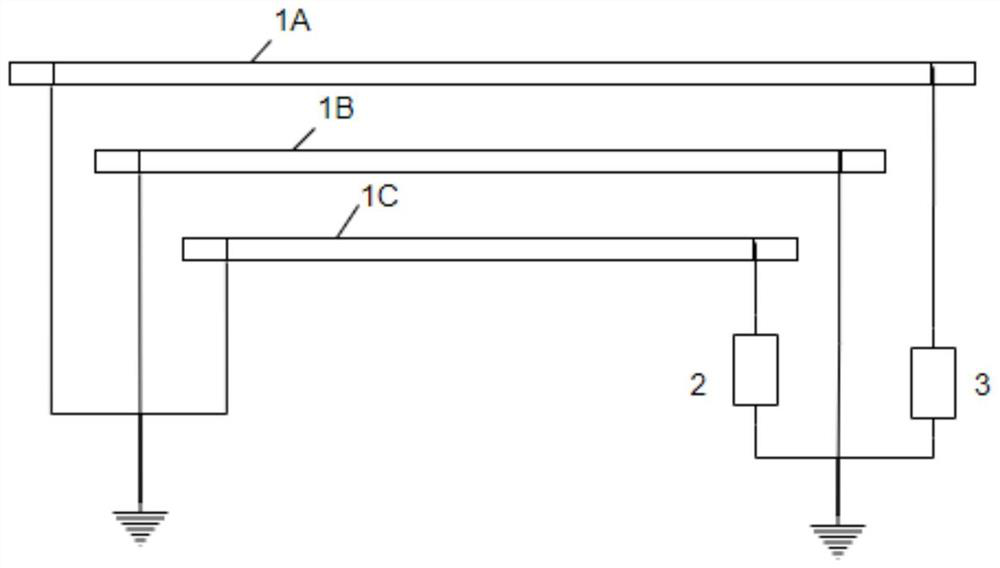

[0103] A high-voltage power cable single-phase sheath double-ended direct grounding method, wherein the high-voltage power cable is a three-phase single-core cable, and both ends of the one-phase single-core cable sheath are directly grounded; the other two-phase single-core cable sheaths are directly grounded; One end is directly grounded, and the other end is connected to the protective device and then grounded;

[0104] When an asymmetric ground fault occurs in the cable line, when one end of the faulty phase single-core cable sheath is directly grounded and the other end is connected to a protection device, part of the ground fault current takes the ground as a loop, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com