Resistance and noise reduction type insulator and high-speed train pantograph with same

A technology for high-speed trains and insulators, applied in the direction of insulators, circuits, current collectors, etc., can solve problems such as limited noise reduction effects, and achieve the effects of stable arrangement, reduced pulsating pressure, and simple structural manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

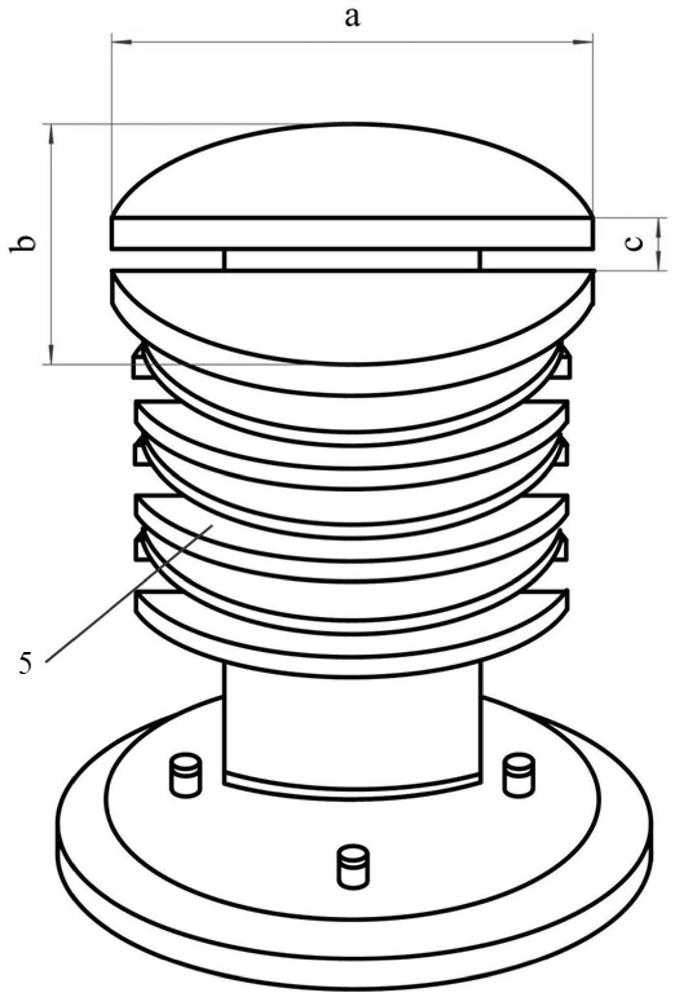

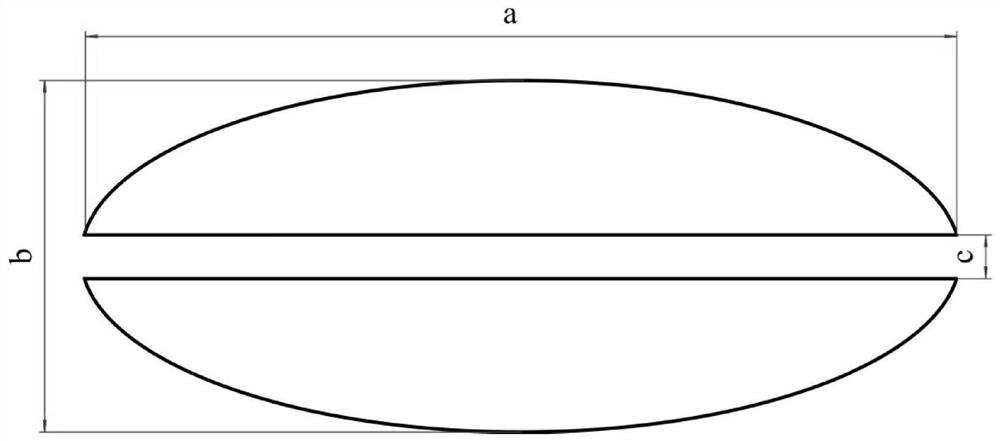

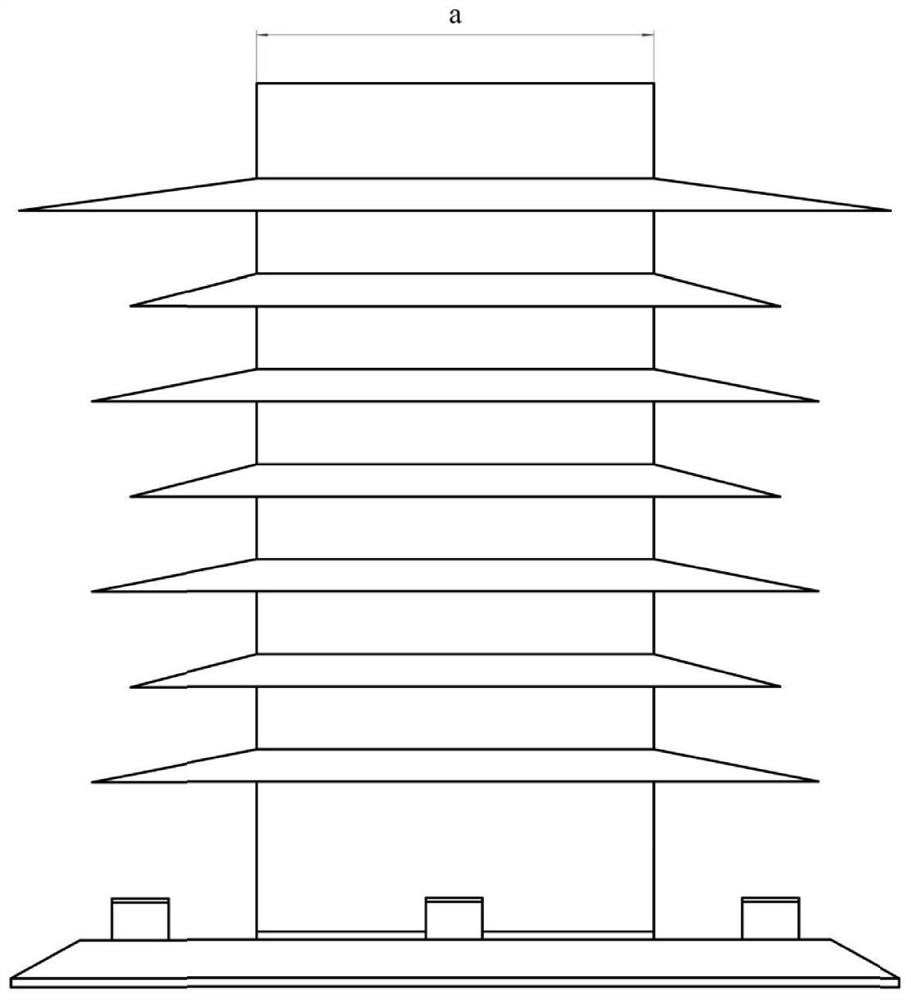

[0034] like Figure 1-4 As shown, a specific embodiment of the present invention is as follows: the ratio of the length of the long axis a to the short axis b of the elliptical cylinder section of the pantograph insulator 5 is 2, and the long axis facing the incoming flow direction is perpendicular to the incoming flow direction. for the short axis. The design width c of the central through hole is 10mm, which is symmetrically distributed along the central axis, and the through hole runs through the entire insulator 5 .

Embodiment 2

[0036] A specific embodiment of the present invention is: the ratio of the length of the long axis a to the short axis b of the elliptical cylinder section of the pantograph insulator 5 is 2.5, the long axis facing the incoming flow direction, and the short axis perpendicular to the incoming flow direction . The design width c of the central through hole is 12.5 mm, which is symmetrically distributed along the central axis, and the through hole runs through the entire insulator 5 .

Embodiment 3

[0038] A specific embodiment of the present invention is as follows: the ratio of the long axis a to the short axis length b of the elliptical cylinder section of the pantograph insulator 5 is 3, the long axis facing the incoming flow direction, and the short axis perpendicular to the incoming flow direction . The design width c of the central through hole is 15 mm, which is symmetrically distributed along the central axis, and the through hole runs through the entire insulator 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com