Waste heat battery heating system

A battery heating system, battery heater technology, applied in batteries, secondary batteries, circuits, etc., can solve problems such as power consumption and insecurity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purposes, technical solutions and advantages of the embodiments of the present disclosure more clear, the technical solutions of the embodiments of the present disclosure will be described clearly and completely below with reference to the accompanying drawings of the embodiments of the present disclosure, in order to maintain the following description of the embodiments of the present disclosure. For clarity and conciseness, the present disclosure omits detailed descriptions of well-known functions and well-known components to avoid unnecessarily obscuring the concepts of the present invention.

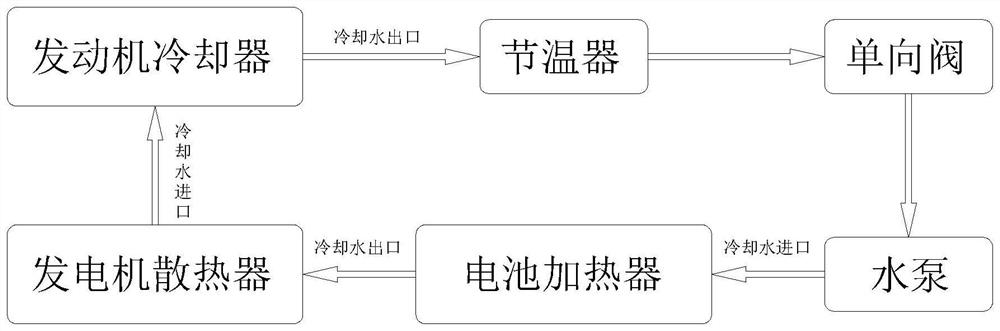

[0016] see figure 1 , a waste heat battery heating system, including an engine cooler, a thermostat, a one-way valve, a water pump, a battery heater and a generator radiator;

[0017] The cooling water outlet of the engine cooler is connected to the water pump through a pipeline, and a thermostat and a one-way valve are installed on the pipeline between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com