Nondestructive lithium-supplementing composite diaphragm as well as preparation method and application thereof

A technology of composite diaphragm and lithium supplementation, applied in the direction of final product manufacturing, sustainable manufacturing/processing, batteries, etc., can solve the problems of restricting applications, high decomposition voltage, etc., solve safety problems, avoid heat shrinkage, improve mechanical strength and The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention also provides a method for preparing a non-destructive lithium-replenishing composite separator, wherein the non-destructive lithium-replenishing composite separator includes: a base film layer and a functional layer, and the functional layer is formed by coating, dipping or filling in the lithium-replenishing slurry. The base film layer is dried and prepared, and the lithium-replenishing slurry contains: an organic lithium-replenishing agent, a catalyst, a conductive agent, a binder and a solvent, wherein the organic lithium-replenishing agent is a lithium carbon oxide compound , the catalyst is a transition metal carbide.

[0021] The solvent can be a solvent commonly used in the art, for example, one or more of N-methylpyrrolidone, tetrahydrofuran, dimethylformamide, water and absolute ethanol. The present invention does not limit the amount of the solvent, as long as the lithium-replenishing slurry can be mixed uniformly.

[0022] The drying m...

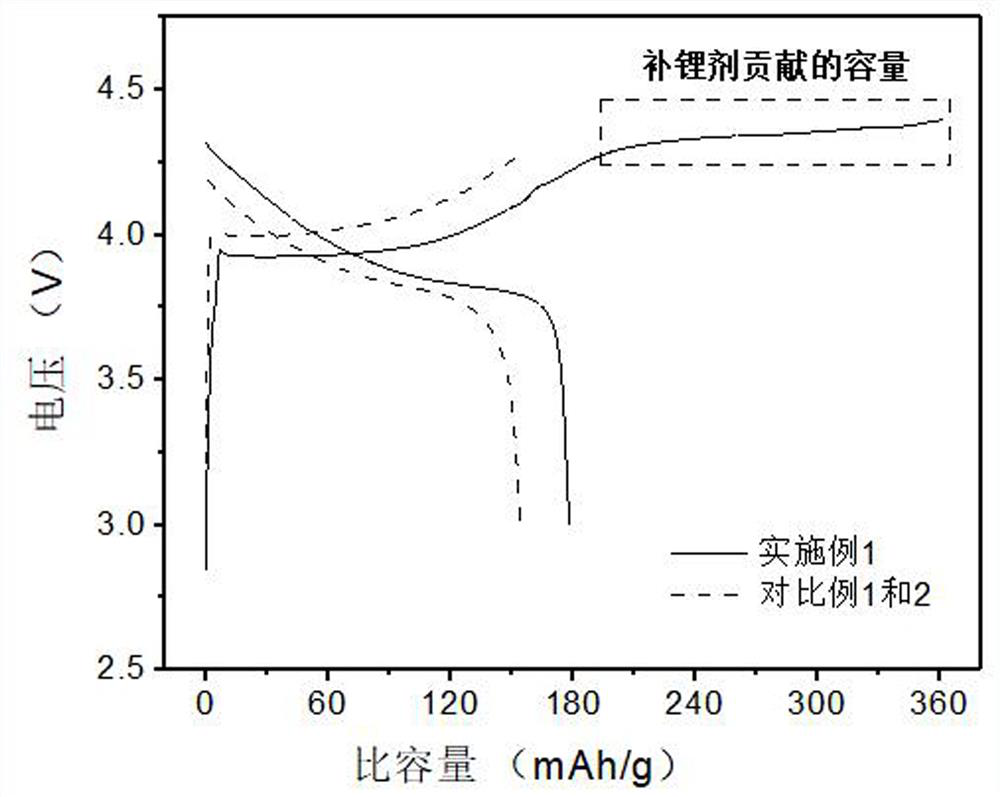

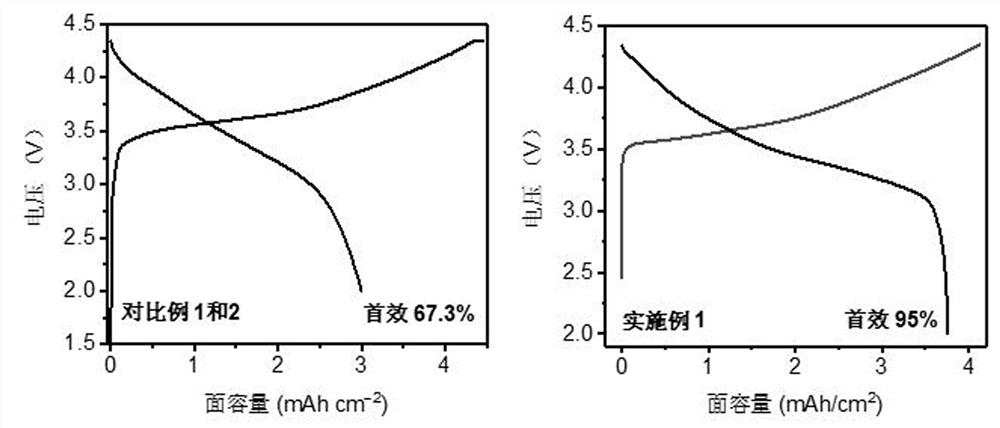

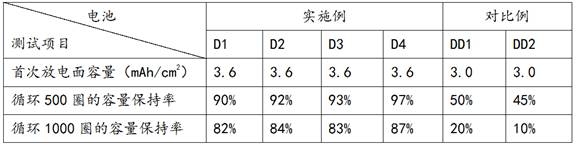

Embodiment 1

[0027] 0.1 g of an organic lithium supplementing agent, 0.5 g of a conductive agent, and 0.3 g of a catalyst are mixed uniformly, and then uniformly mixed with 0.1 g of polyvinylidene fluoride and 2 ml of N-methylpyrrolidone to obtain a lithium supplementary slurry for use.

[0028] The obtained lithium-replenishing slurry is coated on a polypropylene PP film, then vacuum-dried at 100° C. for 12 hours, and then rolled to obtain the non-destructive lithium-replenishing composite separator A1 of the present invention.

Embodiment 2

[0030] 0.5g of organic lithium-supplementing agent, 0.3g of conductive agent, and 0.1g of catalyst were mixed uniformly, and then uniformly mixed with 0.1g of polyvinylidene fluoride and 2ml of N-methylpyrrolidone to obtain a lithium-supplementary slurry for use.

[0031] The obtained lithium-replenishing slurry is coated on a polypropylene PP film, then vacuum-dried at 120° C. for 5 hours, and then rolled to obtain the non-destructive lithium-replenishing composite separator A2 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com