mof-based single-atom lithium-replenishing composite material and preparation method thereof, positive electrode material and battery

A composite material, MOF technology, applied in the field of positive electrode materials and batteries, MOF-based single-atom lithium-supplemented composite materials and their preparation, can solve the problems of unfavorable direct use, high decomposition potential, poor conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present embodiment provides a preparation method of a MOF-based single-atom lithium-supplemented composite material, comprising the following steps:

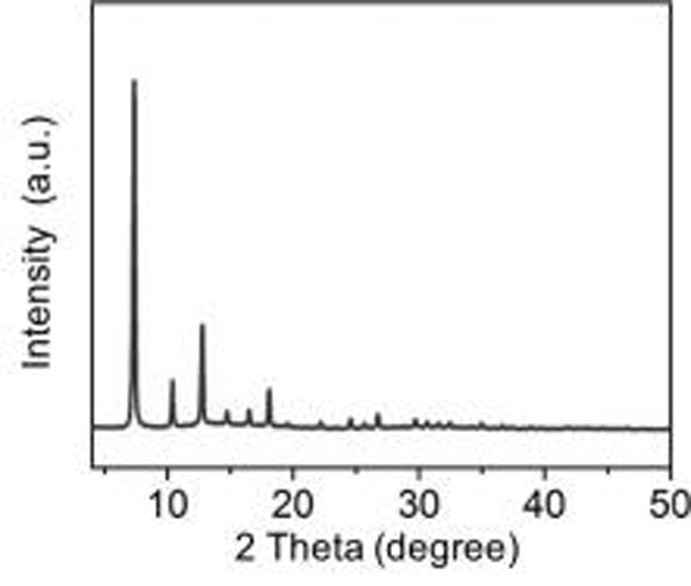

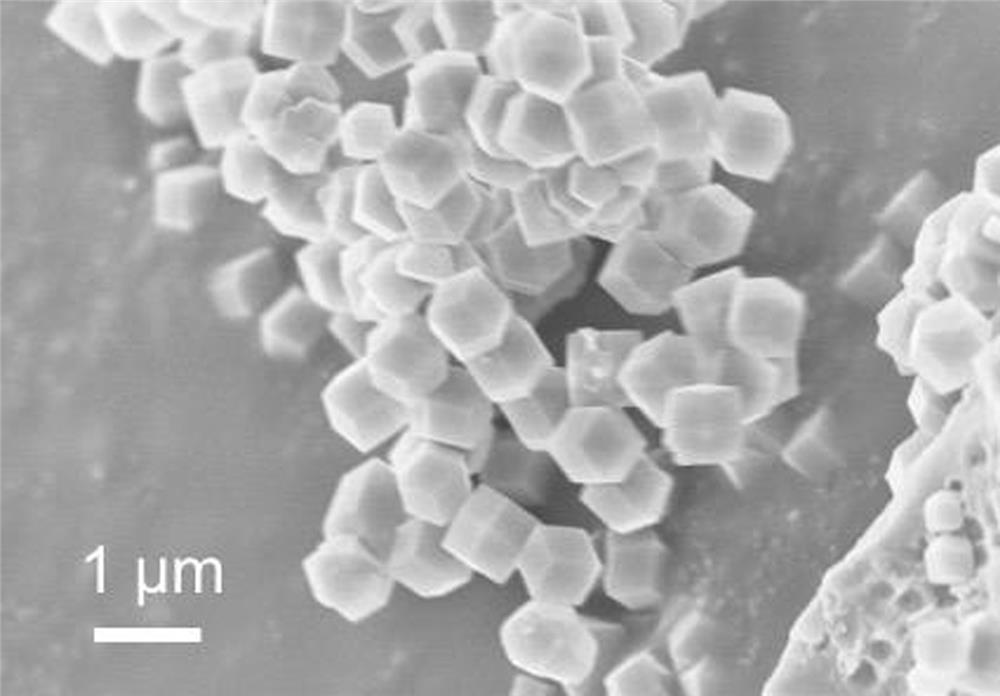

[0036] S1, weigh 1.29g Zn(NO 3 ) 2 ·6H 2 O and 1.62 g of 2-methylimidazole (C 4 H 6 N 2 ), added to 100 mL of methanol, stirred until the solution was clear, and then continued to stir for 30 min. During this process, the solution gradually changed from a colorless clear solution to a white suspension. The obtained white precipitate was washed three times with methanol by centrifugal filtration, and kept in a vacuum oven at 120 °C for about 12 h. At this time, a white powder solid was obtained as ZIF-8, and its X-ray diffraction pattern (XRD) was as follows: figure 1 shown. At the same time, combining figure 2 It can be seen from the SEM results that the synthesized ZIF-8 material is a rhombic dodecahedron with a size of about 1 μm.

[0037] S2, weigh 10mg of MnCl 2 ·4H 2 O was dissolved in 50 mL of ethano...

Embodiment 2

[0045] This embodiment provides a preparation method of MOF-based single-atom lithium-supplemented composite material. The preparation method is basically the same as that of embodiment 1, and the difference is only that: in step S2, the impregnation raw material FeCl is used 3 ZIF-8-Fe is prepared, the target catalyst FeNC obtained in step S3 is denoted as A2, and the composite lithium supplement material prepared in step S4 is denoted as A2-1.

[0046] This embodiment also provides a method for preparing a positive electrode piece and a simulated battery, the steps of which are the same as those in Example 1, and the positive electrodes of the simulated battery are respectively recorded as E2-1 (without lithium cobalt oxide positive electrode material and Ketjen black) and S2 (Contains lithium cobalt oxide cathode material and Ketjen black).

Embodiment 3

[0048] This embodiment provides a preparation method of MOF-based single-atom lithium-supplemented composite material, and the preparation method is basically the same as that of embodiment 1, and the difference is only:

[0049] In step S2, the impregnation raw material CoCl is used 2 ZIF-8-Co is prepared, the target catalyst CoNC obtained in step S3 is denoted as A3, and the composite lithium supplement material prepared in step S4 is denoted as A3-1.

[0050] This embodiment also provides a method for preparing a positive electrode piece and a simulated battery, the steps of which are the same as those in Example 1, and the positive electrodes of the simulated battery are respectively recorded as E3-1 (without lithium cobalt oxide positive electrode material and Ketjen black) and S3 (Contains lithium cobalt oxide cathode material and Ketjen black).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com