A kind of nanometer composite positive electrode lithium supplement slurry and positive electrode

A composite cathode, nanotechnology, applied in the direction of positive electrode, nanotechnology, nanotechnology, etc., can solve the problem that the catalytic effect needs to be further improved, and achieve the effect of good contact, lower decomposition potential, and higher battery charging capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This example is used to illustrate the composite positive electrode lithium supplement slurry and the positive electrode provided by the present invention.

[0038] (1) Preparation of catalyst

[0039] Weigh 1.16g of molybdenum trioxide (MoO 3 ) and 0.4g of carbon nanotubes (CNTs), were added to a ball-milling jar containing balls of different sizes, wherein the ball-to-material ratio was controlled at 20:1, ball-milled at 300rpm for 24h, and then the ball-milled material was placed in a tubular In the furnace, the temperature was raised to 950 °C at a heating rate of 5 °C / min, and sintered for 4 h to obtain Mo nanotube cross-linked. 2 C nanoparticle catalyst, denoted as M1.

[0040] (2) Detection of catalysts

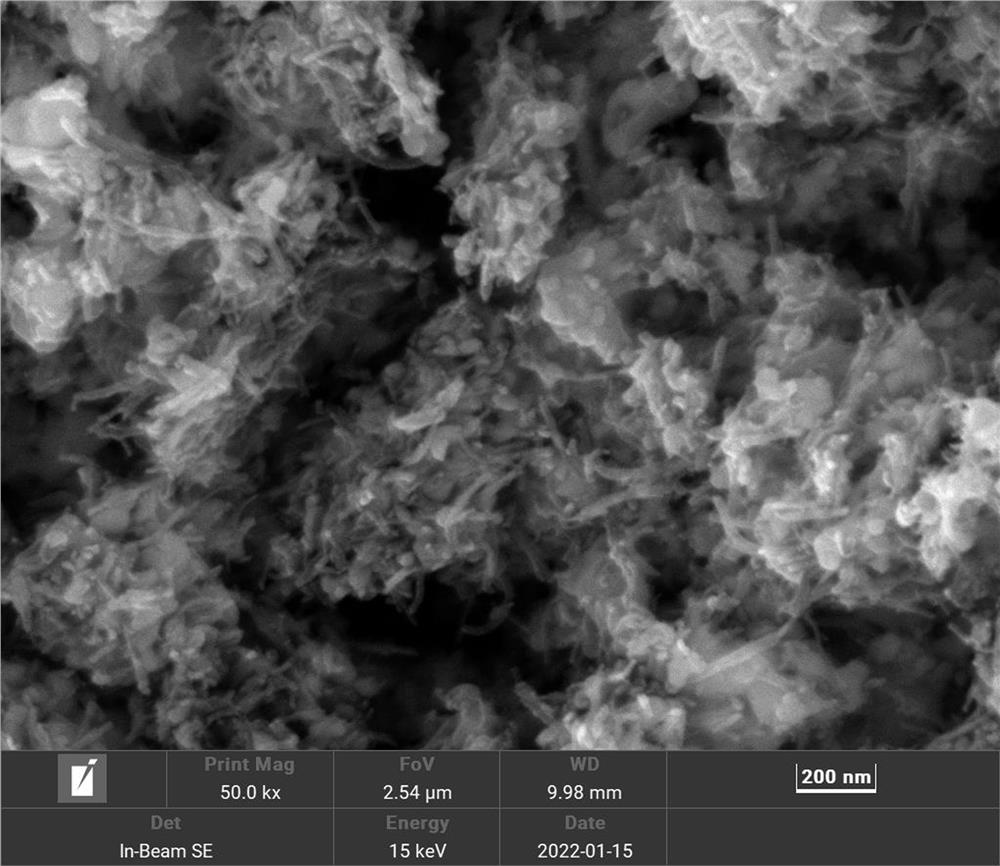

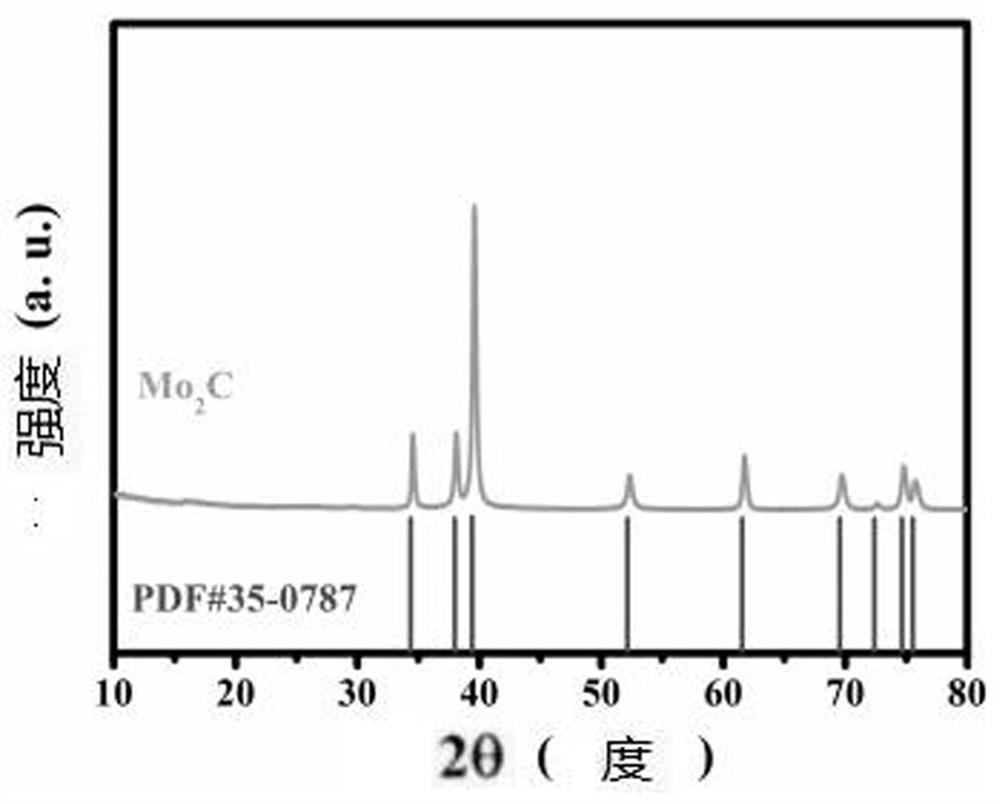

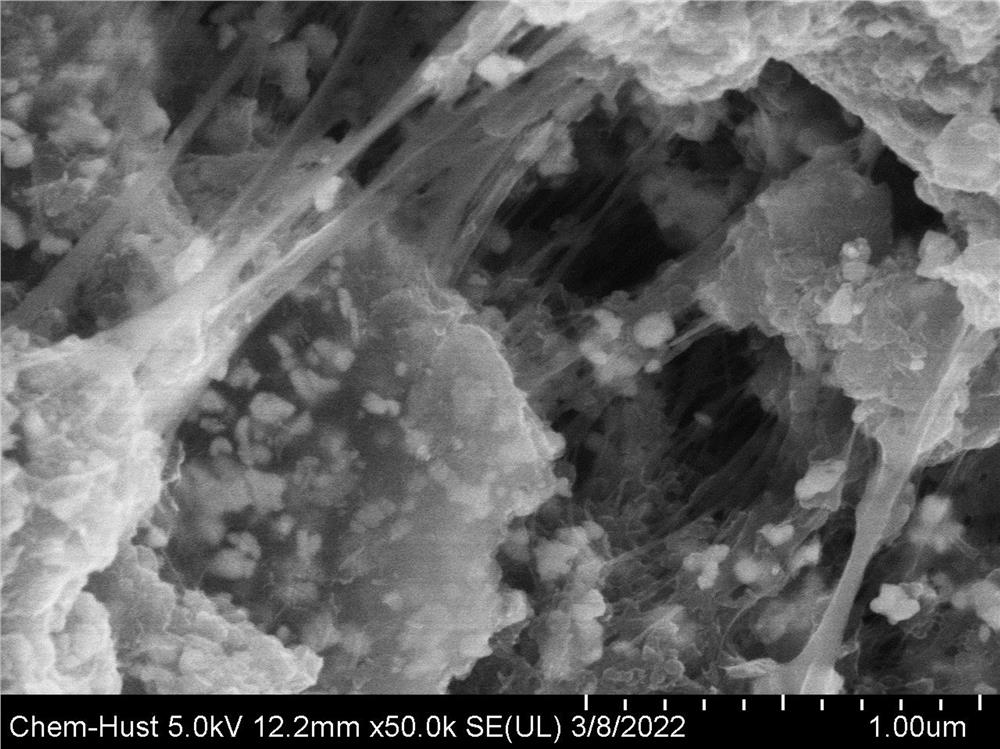

[0041] Field emission scanning electron microscope of M1 (TESCAN MIRA LMS, Czech Republic, accelerating voltage 15 kV) as shown in the picture figure 1 shown, it can be seen from the figure that Mo in M1 2 The C particles are approximately spherical, and th...

Embodiment 2

[0047] This example is used to illustrate the composite positive electrode lithium supplement slurry and the positive electrode provided by the present invention.

[0048] In this embodiment, except that the conditions in the following table 1 are different from those in embodiment 1; and, in step (3), the content of the organic lithium-replenishing material is 90%, and the content of the catalyst is 10%; in step (4) ), the composite lithium supplement material: Super-P: PVDF: NMP = 76:15:9:150, at this time, relative to the composite cathode lithium supplementary slurry, the content of the conductive agent is 6%, and the content of the binder is 3.6%, except that the solvent content was 60%, the same method as in Example 1 was used to prepare a composite positive electrode lithium supplement slurry, and then the composite positive electrode lithium supplement slurry was used to prepare a positive electrode S2.

Embodiment 3

[0050] This example is used to illustrate the composite positive electrode lithium supplement slurry and the positive electrode provided by the present invention.

[0051] In this embodiment, except that the conditions in the following table 1 are different from those in embodiment 1; and, in step (3), the content of the organic lithium-replenishing material is 60%, and the content of the catalyst is 40%; in step (4) ), the composite lithium supplement material: Super-P: PVDF: NMP = 76:15:9:180, at this time, relative to the composite cathode lithium supplementary slurry, the content of the conductive agent is 5.4%, and the content of the binder is 3.2%, except that the solvent content is 64%, the same method as in Example 1 was used to prepare a composite positive electrode lithium supplement slurry, and then the composite positive electrode lithium supplement slurry was used to prepare a positive electrode S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com