Anodic oxidation of 5-aminouracil

An aminopyrimidine, anodizing technology, used in organic chemistry, medical preparations containing active ingredients, pharmaceutical formulas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

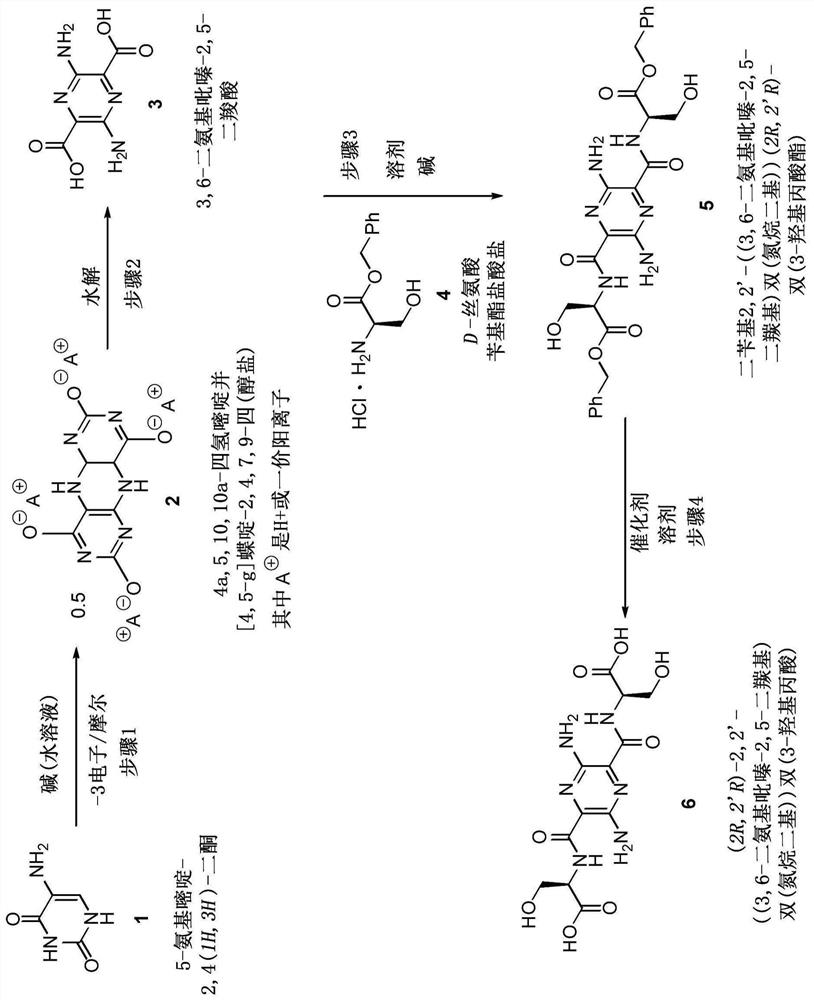

Method used

Image

Examples

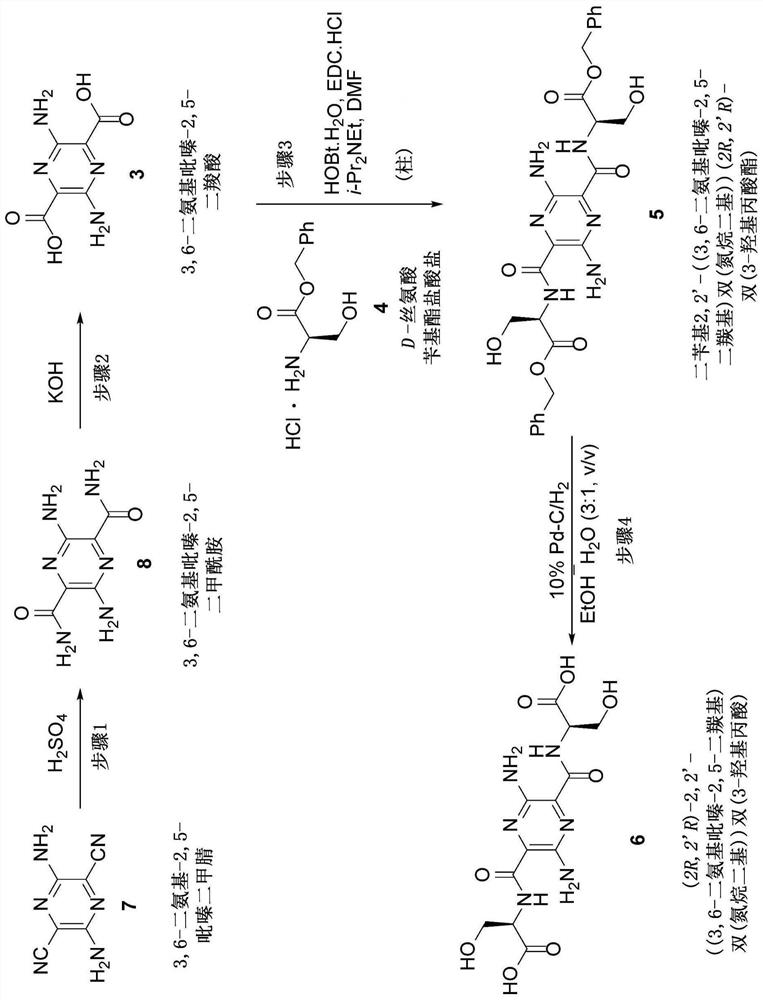

example 2

[0041] General methods for amide formation by coupling of a compound having an amine substituent (eg, compound 4) and a compound having a carboxyl substituent (eg, compound 3) are known to those skilled in the art. Specifically, US 2018 / 0010881 (incorporated herein by reference in its entirety) discloses the formation of compounds, compound 3,6-diamino-N, as shown below 2 ,N 5 -Bis(D-serine)-pyrazine-2,5-dicarboxamide. In step 1, 3,6-diamino-N was formed as shown below 2 ,N 5 -Bis(O-benzyl-(D)-serine methyl ester)-pyrazine-2,5-dicarboxamide. Sodium 3,6-diaminopyrazine-2,5-dicarboxylate (300 mg, 1.24 mmol), (D)-Ser(OBn)-OMe-HCl salt (647 mg, 2.64 mmol), A mixture of HOBt-H2O (570 mg, 3.72 mmol) and EDC-HCl (690 mg, 3.60 mmol) in DMF (25 mL). The resulting mixture was stirred for 16 h and concentrated. The mixture was concentrated to dryness and the residue was partitioned with EtOAc and water. The layers were separated with saturated NaHCO 3 The EtOAc solution was washe...

Embodiment 1

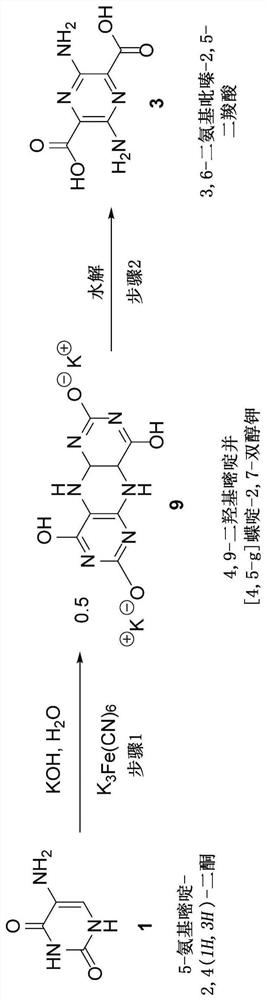

[0104] Potassium 4,9-dihydroxypyrimido[4,5-g]pteridine-2,7-diol was prepared according to the following reaction scheme:

[0105]

[0106] In the first (anode) chamber, a platinum-coated titanium expansion screen was fitted to the inner wall of a Bowers beaker (tall, 400 mL), and a graphite felt anode was placed uniformly on it and lined the inner wall. A stainless steel cathode formed from a 0.25 inch tube was placed in a pvc tube approximately 3 / 4 inch (1.9 cm) outside diameter and approximately 6 inches (15.24 cm) long sealed with clear room temperature vulcanized ("RTV") silicone at one end. in a separate (cathode) chamber formed. The tube was perforated by drilling holes at regular intervals of 1 / 4 inch (0.64 cm) to a distance of approximately 4 inches (10.2 cm) from the bottom of the RTV plug. With 0.15mm (0.006 inch) thick Nafion N324 film, Teflon TM Fabric reinforced (Rf[OCF 2 CF (CF 3 ) 2 ] n OCF 2 CF 2 SO 3 H) Wrap the pvc support tube with the rough side...

Embodiment 2

[0110] 3,6-Diaminopyrazine-2,5-dicarboxylic acid was prepared from potassium 4,9-dihydroxypyrimido[4,5-g]pteridine-2,7-diol according to the following reaction scheme:

[0111]

[0112]In each of the two Teflon reaction vessels place 0.5 g of potassium 4,9-dihydroxypyrimido[4,5-g]pteridine-2,7-diol and 0.3 to 10 mL of deionized water A solution of 0.4 g of sodium hydroxide. The vessel was set in a microwave reactor and allowed to react at 170°C and about 100 psig pressure for 1 hour. The vessel was cooled to about 50°C and the contents were filtered to remove a small amount of solid residue. The bright yellow filtrate was transferred to a 250 mL round bottom flask equipped with a large magnetic stir bar. The pH was adjusted to about 3 with stirring with concentrated HCl, resulting in the formation of a large red precipitate. A few drops of acid were added and the solid was collected by filtration on fritted glass, rinsed with cold 1N HCl (1 x 10 mL), acetonitrile (2 x 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com