Die-casting aluminum alloy, aluminum alloy die casting and manufacturing method of aluminum alloy die casting

A technology for casting aluminum alloys and manufacturing methods, which is applied in the field of aluminum alloy die-casting parts and its manufacture, and the field of die-casting aluminum alloys, which can solve problems such as inability to integrate, shorten processing time, and reduce tool wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

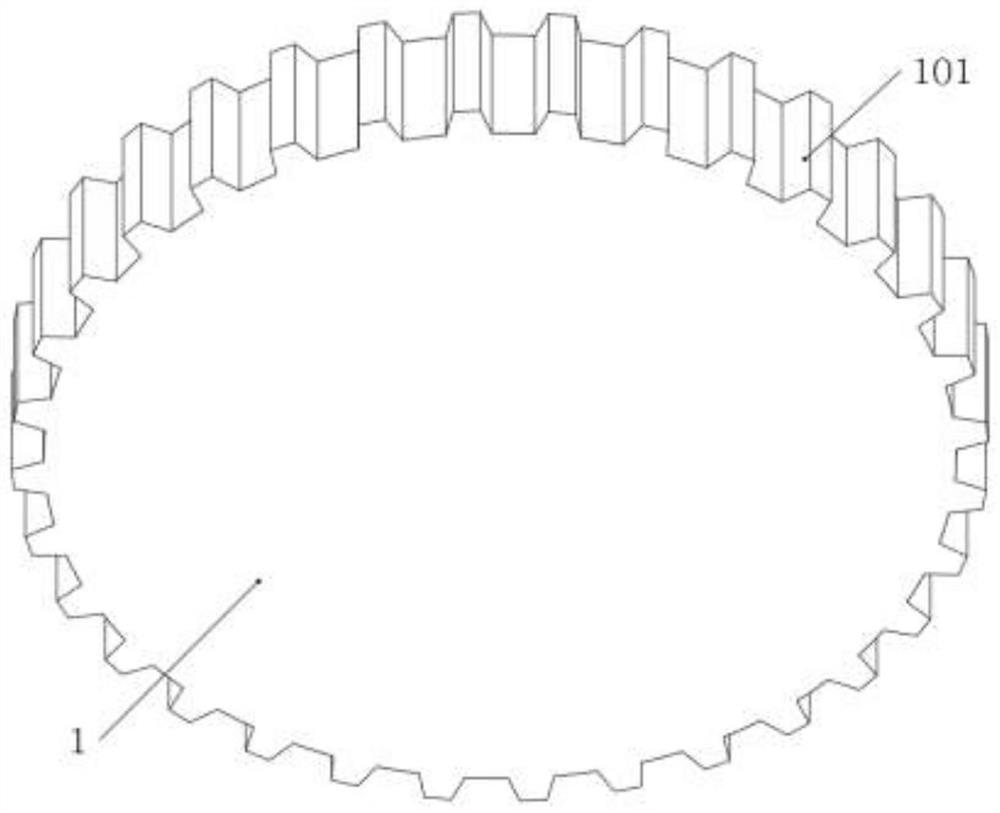

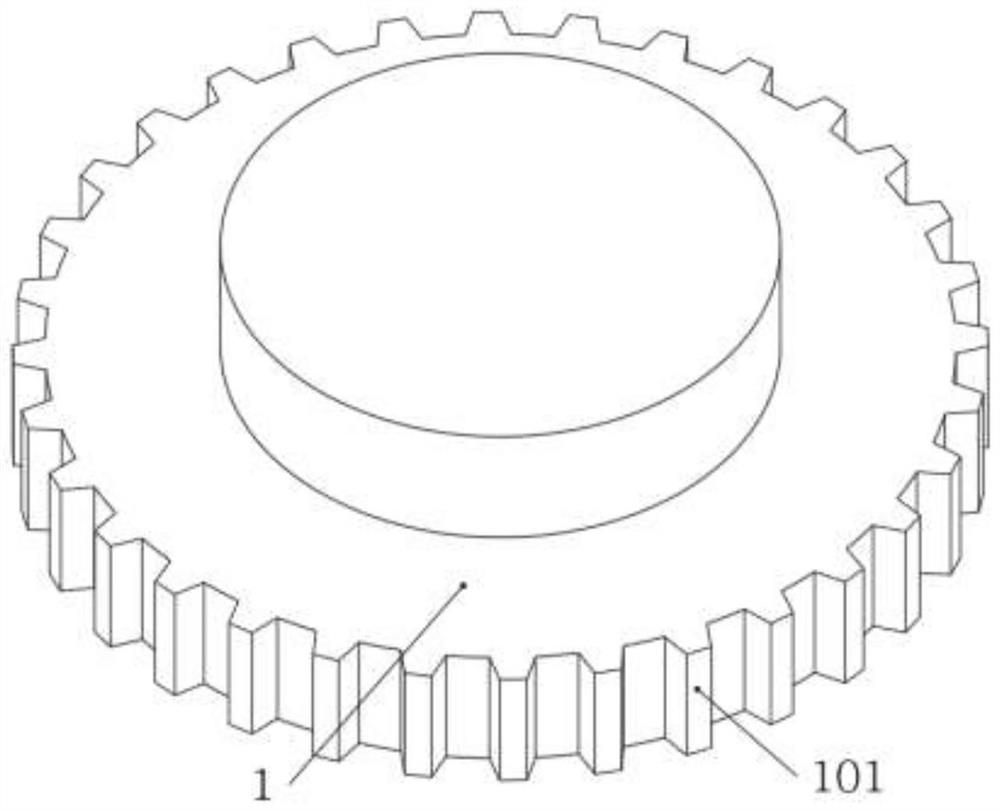

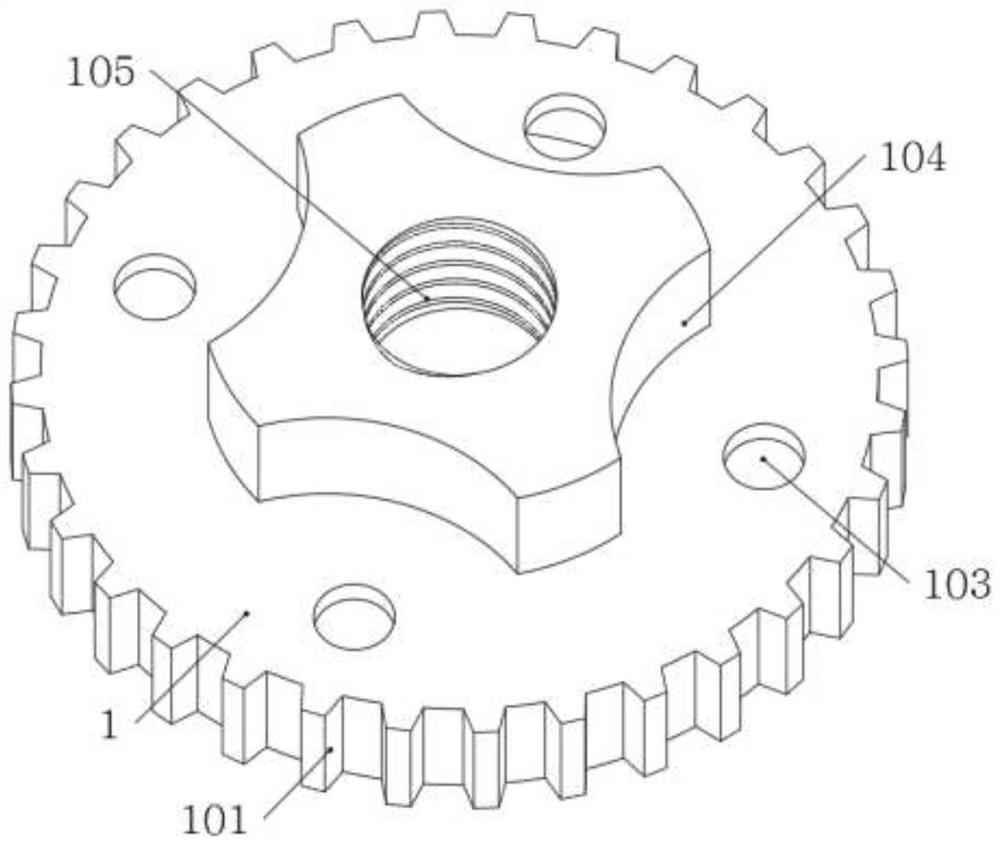

[0038] as attached figure 1 to the attached Figure 8 shown:

[0039] The present invention provides a die-casting aluminum alloy, an aluminum alloy die-casting part and a manufacturing method thereof, comprising a part main body 1; the part main body 1 is a stepped structure, and the part main body 1 is formed by die casting; A102 is a cylindrical groove-like structure, and the diameter of the groove A102 is 20cm, and the groove A102 is formed by lathe processing; because the diameter of the groove A102 is larger, it can be processed more quickly by a lathe; through holes 103 and 103 are in total There are four through holes 103, and the four through holes 103 are opened on the part body 1 in an annular array; the diameter of the four through holes 103 of the applicant is 2cm; the four through holes 103 are all cylindrical hole-shaped structures, and the four The four through holes 103 are formed by a drilling machine; after the groove A102 is processed, the processing time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com