Printing method, device and equipment for adjusting processing liquid data in combination with image data

A technology of image data and processing liquid, applied in printing devices, printing and other directions, can solve the problems of waste of resources and large consumption of processing liquid, and achieve the effect of saving resources and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

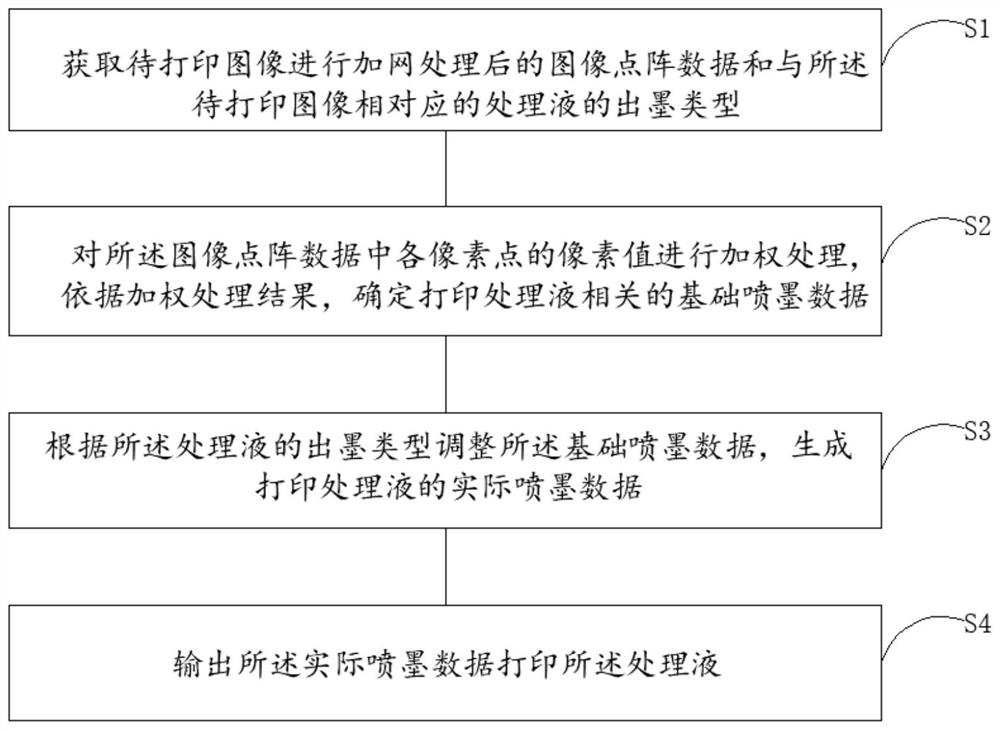

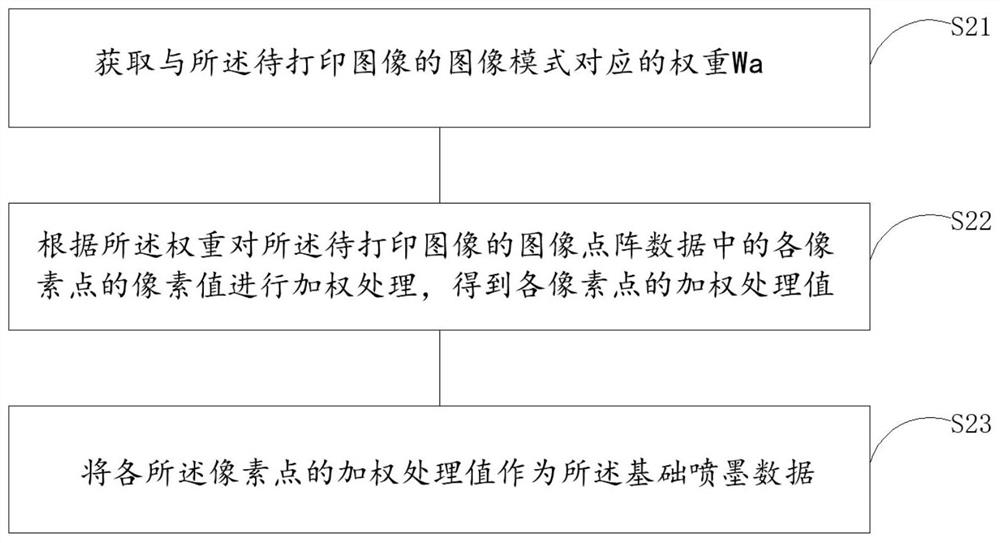

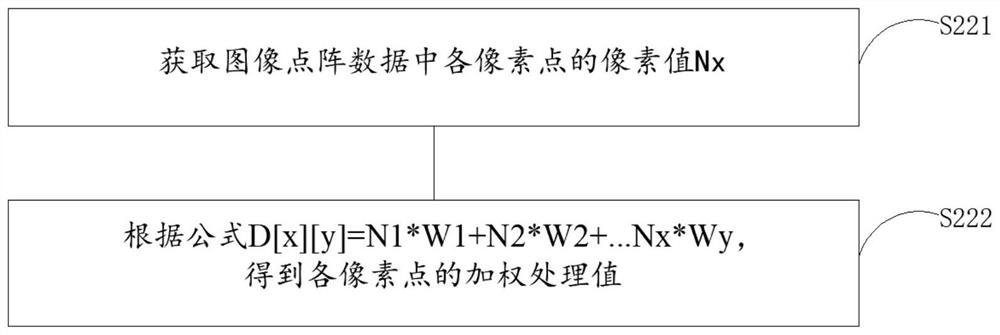

[0049] figure 1 A schematic flowchart of a printing method for adjusting processing fluid data in combination with image data provided in Embodiment 1 of the present invention, as shown in figure 1 As shown, the method includes:

[0050] S1: Obtain the image dot matrix data of the to-be-printed image after screen processing and the ink discharge type of the processing liquid corresponding to the to-be-printed image;

[0051] Specifically, the image information of the image to be printed is stored in different image channels through color characteristics, a special image channel is added to store the image information of the spot color, and the image data is stored in the form of a data dot matrix, wherein the data point Each point in the matrix corresponds to each pixel point of the image data one-to-one, that is to say, each point in the data lattice is used to represent the pixel point of the image data; the processing liquid data is stored in the same way. In the image ch...

Embodiment 2

[0111] The present invention also provides a processing liquid data printing device, such as Figure 5 shown, including:

[0112] Data acquisition module: used to acquire the image dot matrix data of the to-be-printed image after screen processing and the ink discharge type of the processing liquid corresponding to the to-be-printed image;

[0113] Data processing module: used to perform weighting processing on the pixel value of each pixel in the image lattice data, and determine the basic inkjet data related to the printing treatment liquid according to the weighting processing result;

[0114] Data conversion module: used to adjust the basic inkjet data according to the ink discharge type of the treatment liquid, and generate the actual inkjet data of the printing treatment liquid;

[0115] Liquid data printing module: used to output the actual inkjet data to print the treatment liquid.

[0116] The processing liquid data printing device provided in the second embodiment ...

Embodiment 3

[0139] Embodiment 3 of the present invention discloses a printing device, such as Image 6 As shown, at least one processor, at least one memory, and computer program instructions stored in the memory are included.

[0140] Specifically, the above-mentioned processor may include a central processing unit (CPU), or a specific integrated circuit (Application Specific Integrated Circuit, ASIC), or may be configured to implement one or more integrated circuits of the embodiments of the present invention.

[0141] Memory may include mass storage for data or instructions. By way of example and not limitation, memory may include a Hard Disk Drive (HDD), floppy disk drive, flash memory, optical disk, magneto-optical disk, magnetic tape or Universal Serial Bus (USB) drive or two or more a combination of more than one of these. Storage may include removable or non-removable (or fixed) media, where appropriate. Where appropriate, the memory may be internal or external to the data proc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap