Construction method of underground continuous pouring concrete pile wall

A technology of pouring concrete and construction method, applied in sheet pile wall, excavation, foundation structure engineering and other directions, can solve the problems of low efficiency, long construction period and high cost, and achieve the effect of simple construction process, low construction cost and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

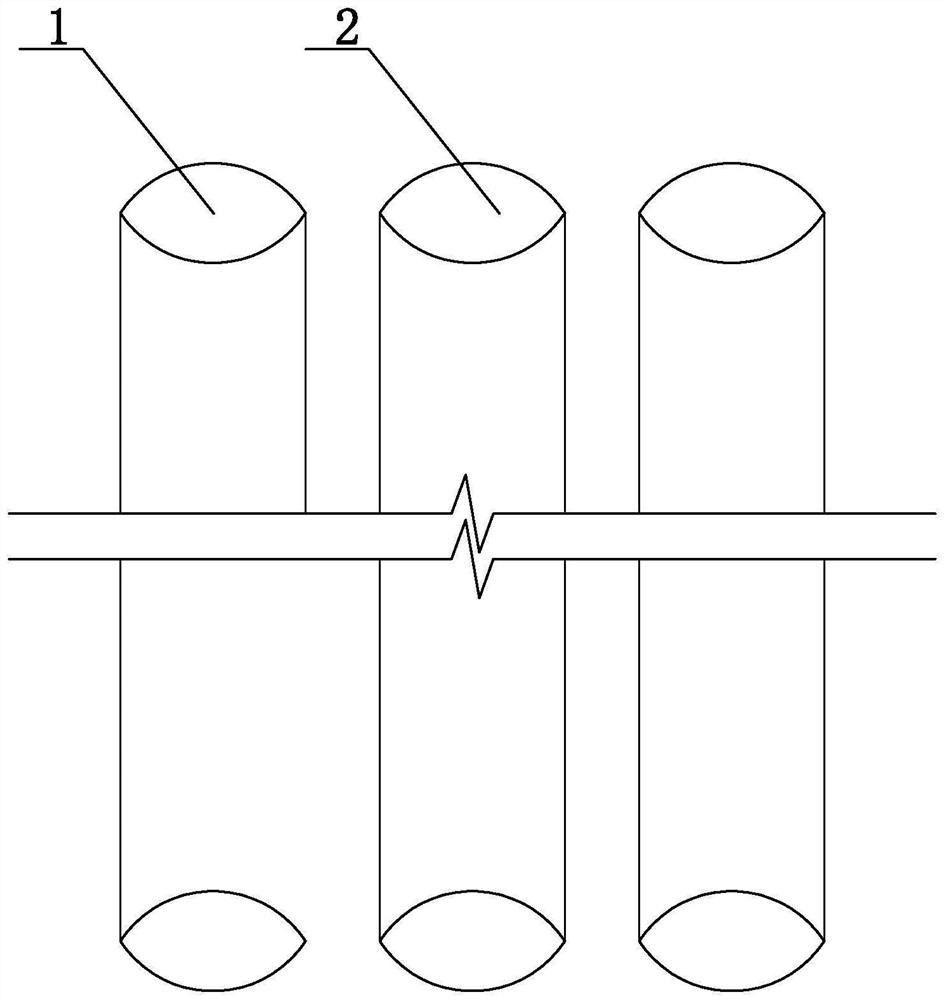

[0036] Specific implementation one: as Figure 1-Figure 12 As shown, the present embodiment discloses a construction method for an underground continuous cast-in-place concrete pile wall, and the method includes the following steps:

[0037] Step 1: Use a drilling rig to drill multiple A pile holes to the design depth. The multiple A pile holes are sequentially defined as A1 pile holes 1 to An pile holes from the head A pile hole to the end A pile hole, and n is divided by zero A natural number other than ; and fill all A pile holes with mud;

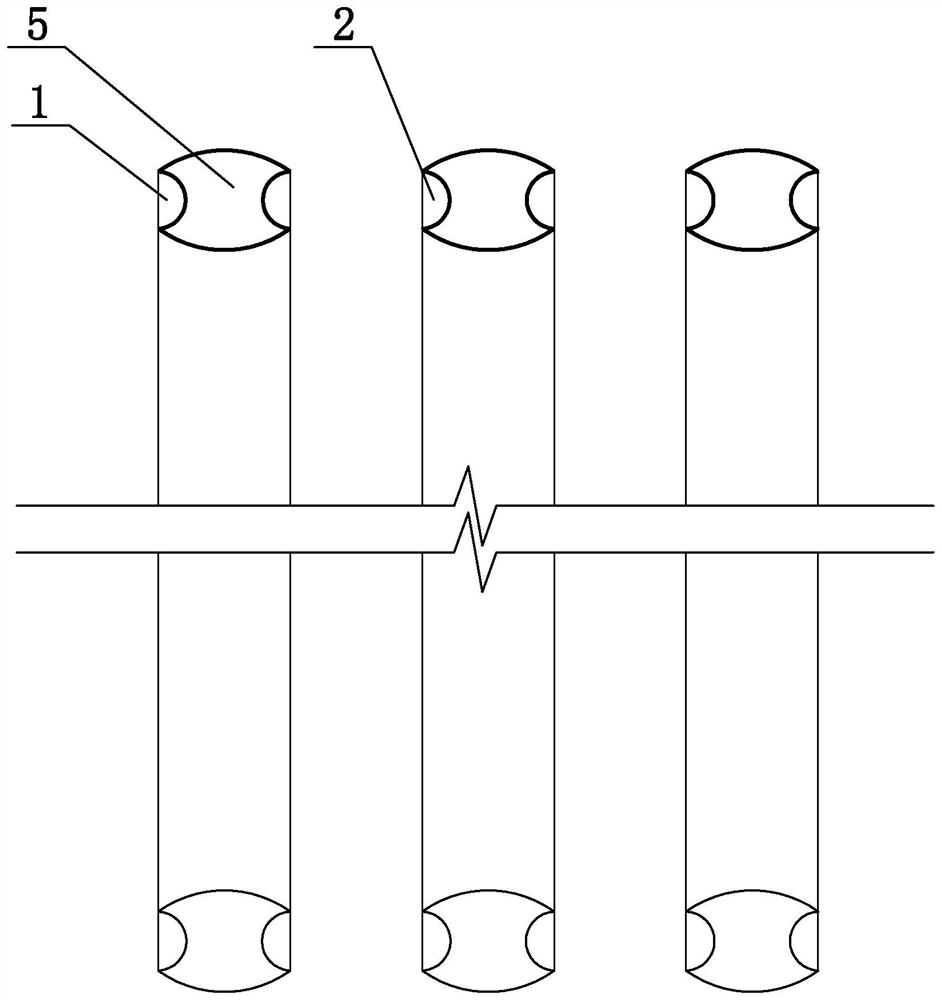

[0038] Step 2: First prepare a plurality of steel cylinder models 5, each steel cylinder model 5 is composed of two convex arc side walls 5-1 and two concave arc side walls 5-2, the two convex arc side walls The wall 5-1 and the two concave arc side walls 5-2 are respectively arranged symmetrically, and one end of the two convex arc side walls 5-1 on the same side is connected with both ends of the concave arc side wall 5-2; , put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com