Steel structure plant maintenance plate reinforcing structure and using method thereof

A technology for strengthening structures and maintenance panels, which is applied in building maintenance, building components, building structures, etc., can solve problems such as poor reinforcement effect of maintenance panels, achieve good reinforcement effects, avoid loose installation, and avoid loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

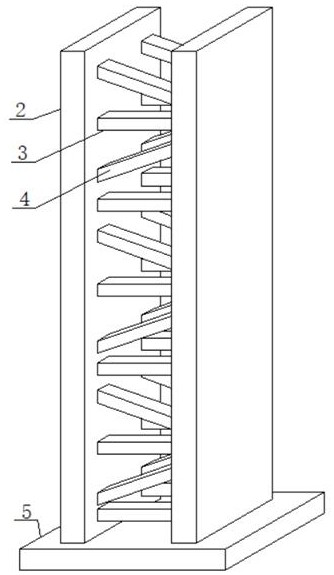

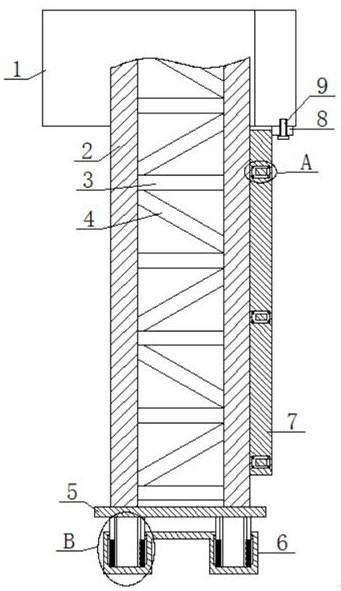

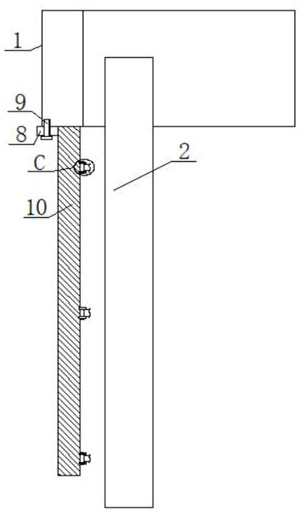

[0038] Embodiment 1: as Figure 1-10As shown, the maintenance board reinforcement structure of the steel structure workshop includes the maintenance board body 1, and the inner cavity of the maintenance board body 1 is provided with two vertical boards 2, and the two vertical boards 2 are arranged on the left and right, and the two vertical boards 2 are close to the front and rear Both sides are fixedly connected with several transverse reinforcing ribs 3, and the tops of several transverse reinforcing ribs 3 are provided with oblique reinforcing ribs 4, and both sides of the oblique reinforcing ribs 4 are respectively fixedly connected with the opposite sides of the two vertical plates 2, Two adjacent oblique reinforcing ribs 4 are symmetrically arranged up and down with the central axis of the transverse reinforcing rib 3 as the axis of symmetry. Several connecting ribs 11, the top view cross-section of connecting ribs 11 is L-shaped setting, several connecting ribs 11 are a...

Embodiment 2

[0046] Embodiment 2: A method of using a steel structure factory building maintenance board reinforcement structure, the steel structure factory building maintenance board reinforcement structure in this embodiment is as described in Embodiment 1, including the following steps:

[0047] S1: When in use, place the two vertical plates 2 fixed with the transverse reinforcing rib 3 and the oblique reinforcing rib 4 inside the main body 1 of the maintenance plate near the four corners.

[0048] S2: Then the first connecting plate 7 and the second connecting plate 10 are fixedly connected to the bottom surface of the maintenance plate body 1 through the first connecting piece 8 and the first bolt 9 respectively, and since the first connecting plate 7 and the side of the right vertical plate 2 The wall is fixed so that the first connecting plate 7 is installed stably.

[0049] S3: Then fix one end of the connecting rib 11 to the front side wall of the first connecting plate 7 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com