Equipment inspection and spot inspection program

A point inspection and equipment technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as damage, inconvenient management and storage, and easy loss of paper forms on the machine table, saving paper and not easy to miss inspections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

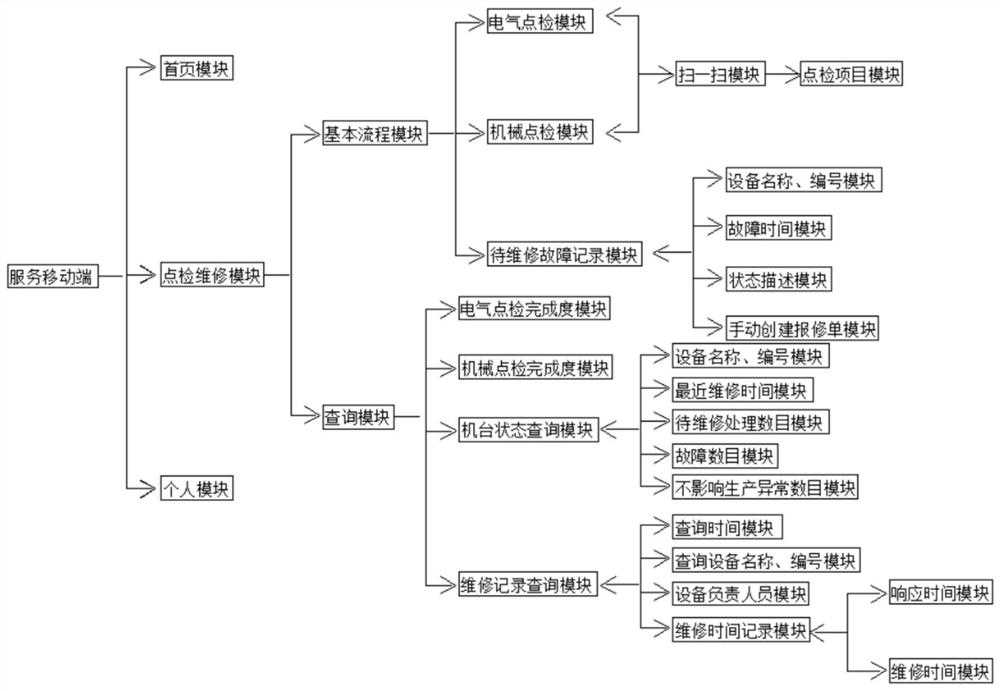

[0026] Equipment inspection and inspection procedures, including:

[0027] The mobile server is used to carry equipment inspection, point inspection, maintenance procedures, and realize the interaction between people and procedures;

[0028] The home page module is a module used to display the company name and image;

[0029] The point inspection and maintenance module is used to introduce and query the basic process of the point inspection and maintenance program, including electrical point inspection, mechanical point inspection and failure records to be repaired;

[0030] The personal module is used to record personal basic information and summarize and display it. The module contains text, audio, images, etc. uploaded since login.

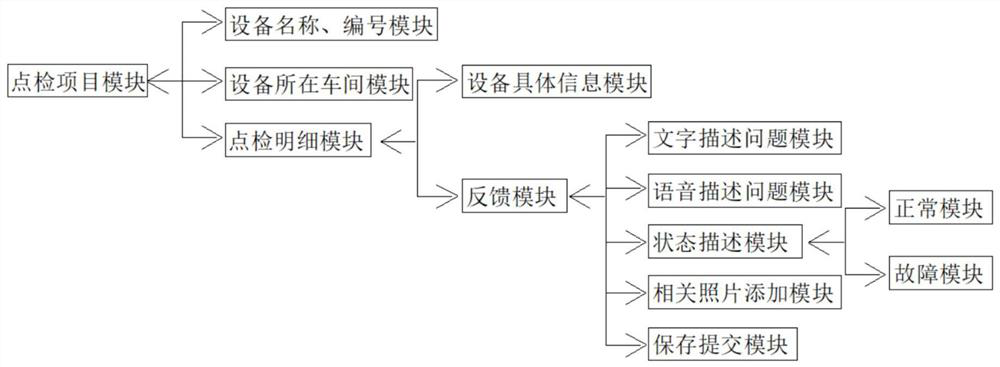

[0031] First log in to the service mobile terminal, select the inspection and maintenance module in the options of the mobile terminal, after entering the inspection and maintenance module, it is divided into the basic process module and the q...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap