Novel hybrid excitation asynchronous starting permanent magnet synchronous motor stator and rotor structure

A technology of permanent magnet synchronous motor and mixed excitation, which is applied in the direction of magnetic circuit shape/style/structure, motor, and magnetic circuit rotating parts, etc. Low power density and other issues, achieve the effects of small cogging torque, shortened starting time, and easy magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

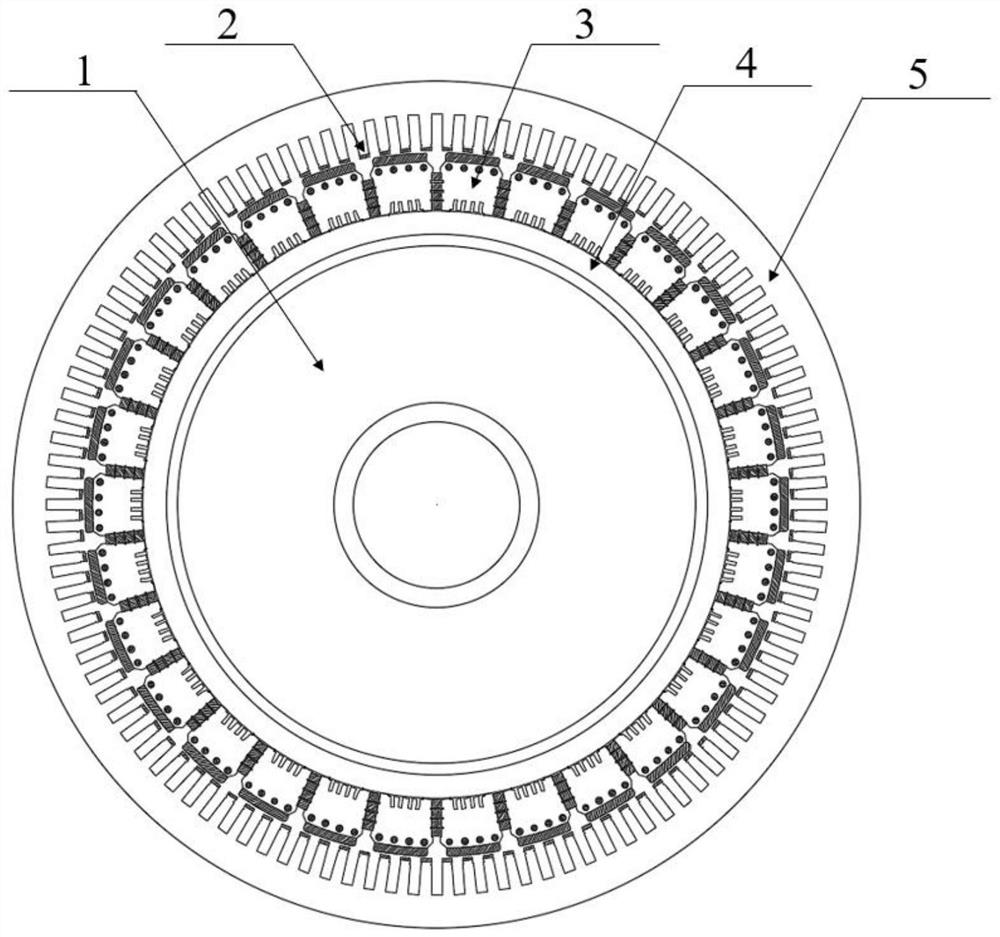

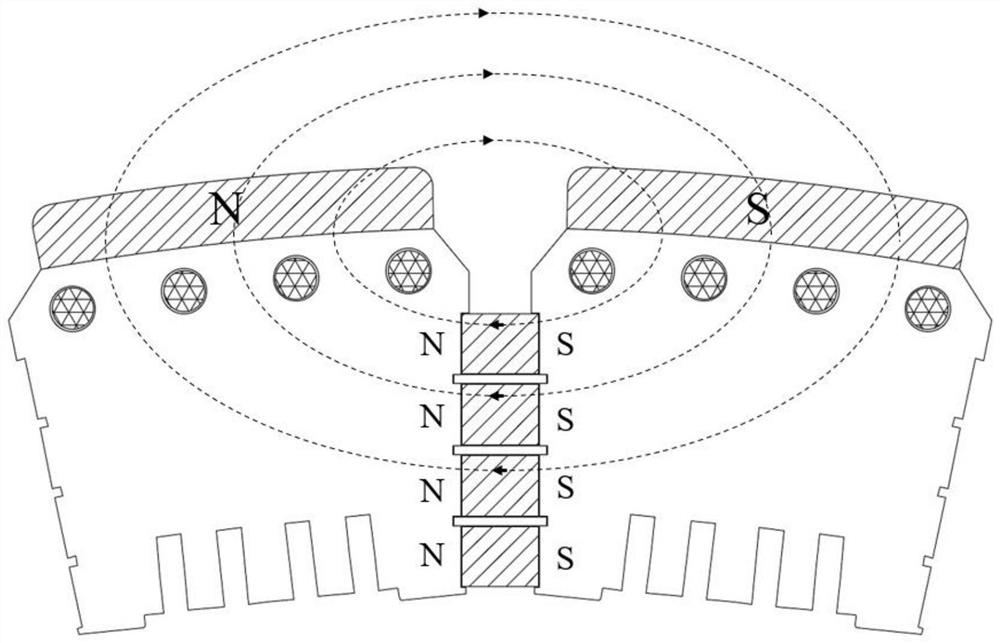

[0017] refer to figure 1 As shown in the figure, a 30-pole 108-slot asynchronous starting permanent magnet synchronous motor is used for design. The motor structure is that the stator is outside and the rotor is inside. The windings are double-layer windings, which are installed on the stator teeth. , There are four circular holes with a radius of 5mm on the top of the rotor pole for placing damping bars, so as to realize the self-starting function of the motor.

[0018] refer to figure 1 As shown, for the stator: each stator tooth top is installed with a magnet-adjusting block, which can convert the stator teeth of the motor into magnetic teeth, which can increase the torque density of the motor and shorten the starting time.

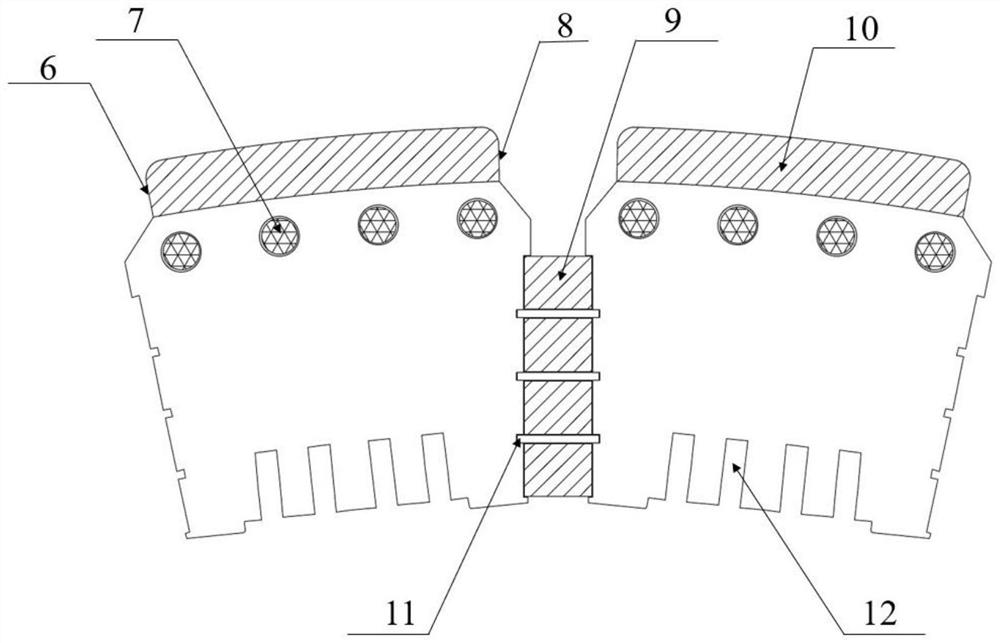

[0019] refer to figure 2 As shown, for the rotor: there are three equal-sized rectangular aluminum alloy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com