Method for improving flavor of tea soup and tea leaf extract

A technology for extracting and tea leaves, which is applied in the field of improving the flavor of tea soup and tea extracts, and can solve problems that affect consumers' taste experience, large molecular weight, and easy precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

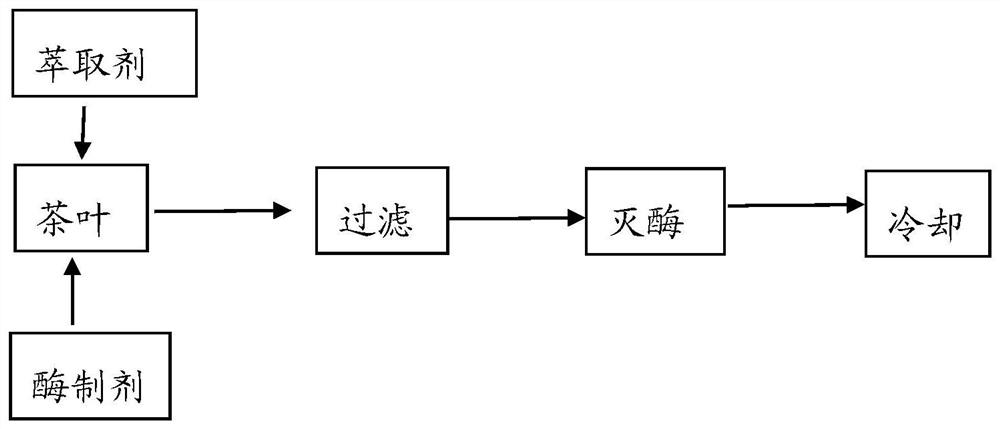

[0028] like figure 1 As shown, the method of this embodiment includes the following steps:

[0029] Tea: Weigh 50g Ceylon black tea, size 20-30 mesh.

[0030] Extraction agent heating: add 1000g extractant to the extraction tank and heat to the enzymatic hydrolysis temperature.

[0031] Extraction: 50g of Ceylon black tea was weighed in advance and added to the extraction agent, and the extraction temperature was controlled within the enzymatic hydrolysis temperature range.

[0032] Enzymatic hydrolysis: After adding tea leaves, add protease to the extraction tank, and control the enzymatic hydrolysis time according to the experimental plan.

[0033] Enzyme inactivation: Inactivate the enzyme at 95°C / 10min after enzymatic hydrolysis.

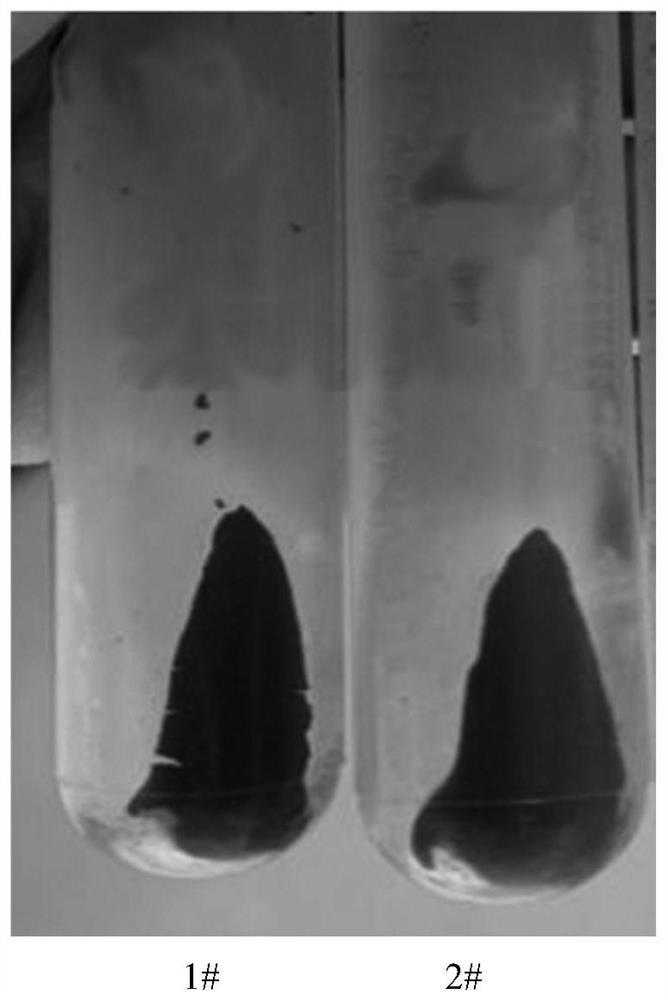

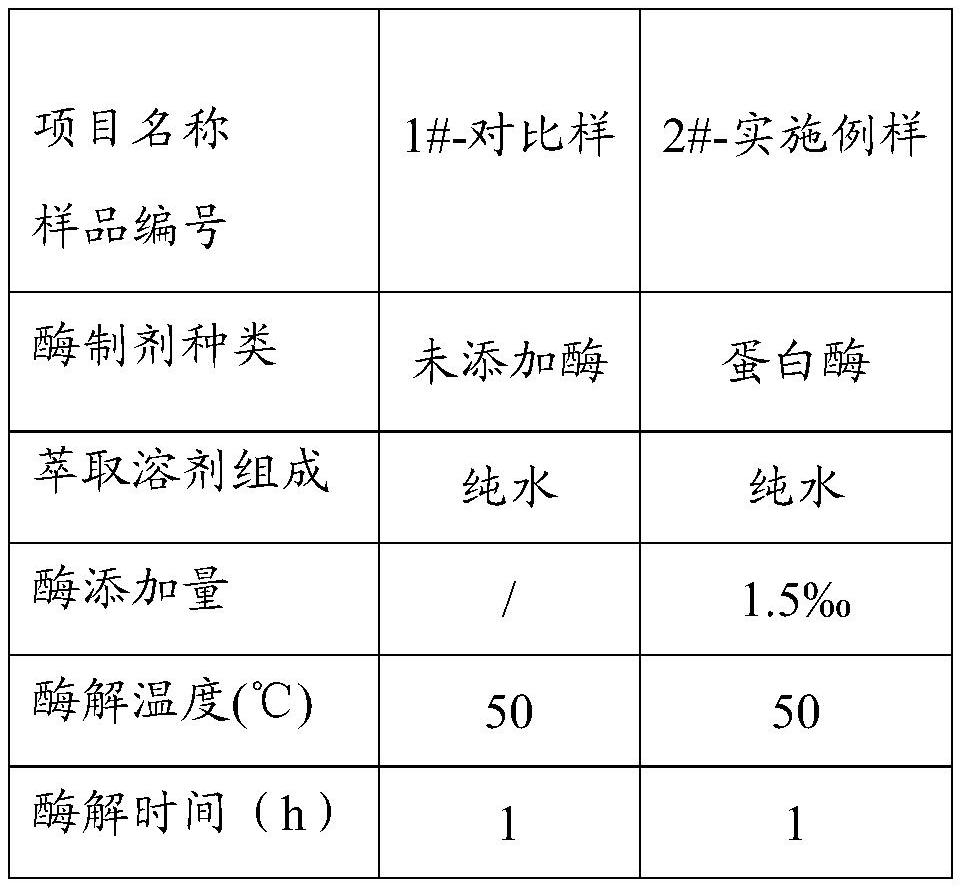

[0034] Cooling: Cool the tea soup after deactivating the enzyme to a room temperature of 25°C, taste the taste, and conduct centrifugation precipitation detection. The results are shown in Table 1 and figure 2 middle.

Table 1: Experiment...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap