Anatomical patellofemoral joint prosthesis

A femoral, anatomical technology, applied in prosthesis, knee joint, elbow joint, etc., can solve the problems of patellar prosthesis wear, skin coloration, high shear force of patella joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

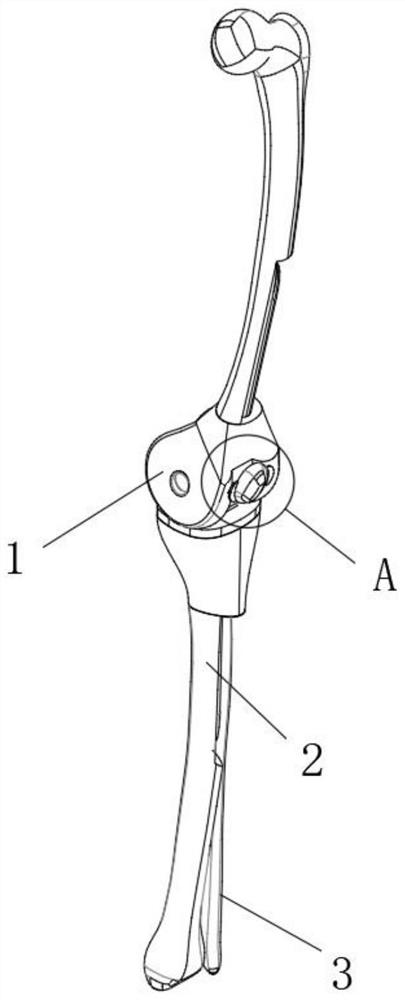

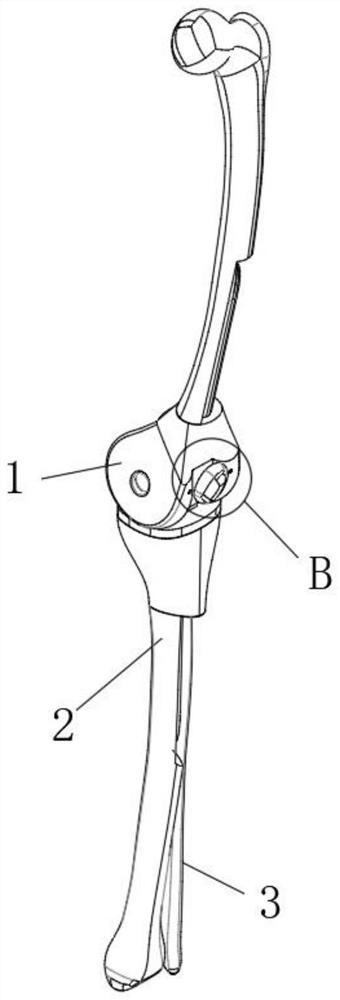

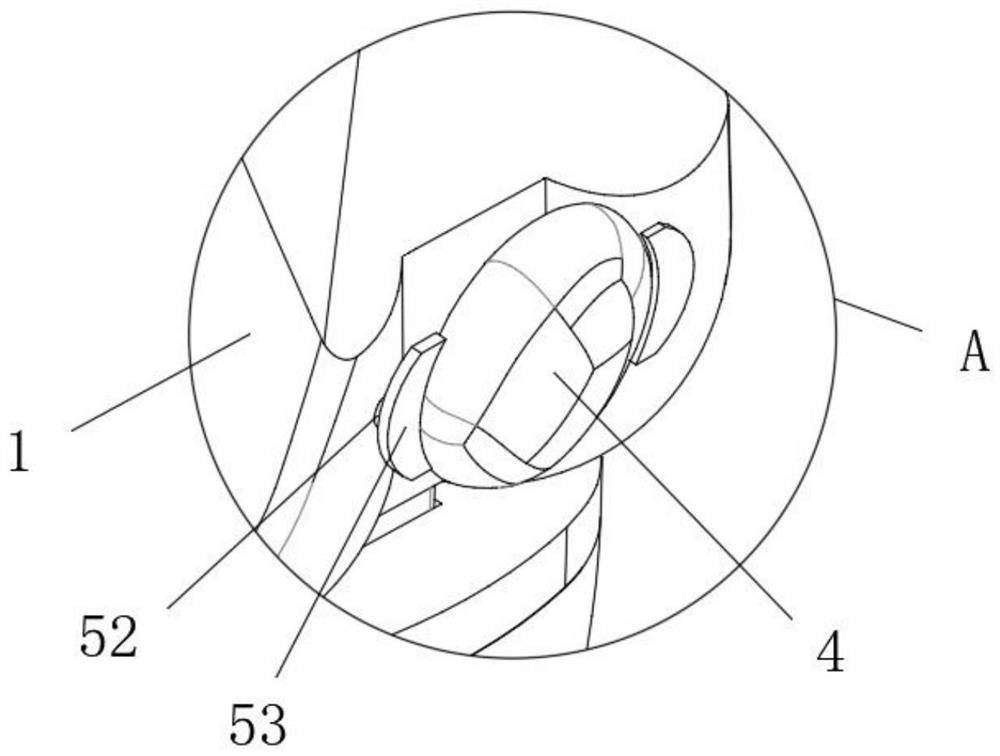

[0033] like figure 1 - Figure 7 As shown, an anatomical patellofemoral joint prosthesis comprises a femoral part 1, a fibula part 2 is connected to the femoral part 1, a tibia part 3 is connected to one side of the fibula part 2, a patella part 4 is installed on the femoral part 1, A mounting assembly 5 is provided on the outer wall of the femoral portion 1, and the mounting assembly 5 includes a threaded fastening groove 51 opened in the inner walls of both sides of the femoral portion 1, a threaded fastening rod 52 threadedly connected with the threaded fastening groove 51, and fixed on the threaded fastening groove 51. The limit mounting plate 53 on the outer wall of the rod 52 and the upper and lower ends of the patella portion 4 are respectively connected with the quadriceps femoris muscle 6 and the patellar tendon 7 .

[0034]Two screw fastening grooves 51 are provided on the outer wall of the femoral part 1 at the contact position of the femoral part 1 and the patella...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com