Filtering device for processing high-quality and high-yield oil plants

A filter device and high-yield technology, applied in the field of oil processing, can solve the problems of in-depth treatment, affecting oil yield, oil loss, etc., and achieve the effect of improving oil yield, improving production efficiency, and facilitating extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

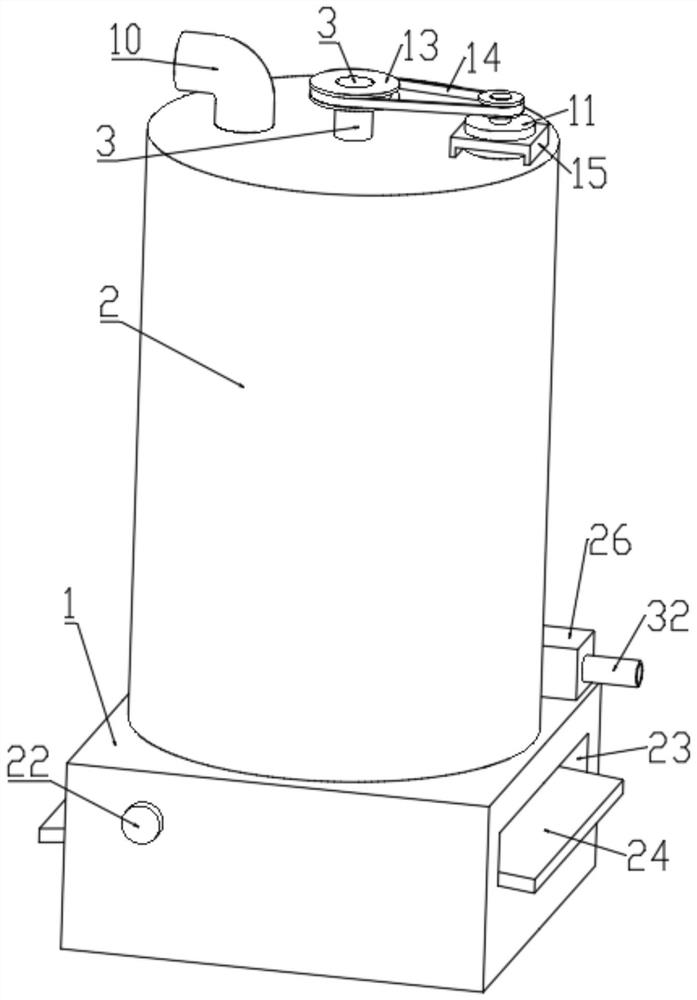

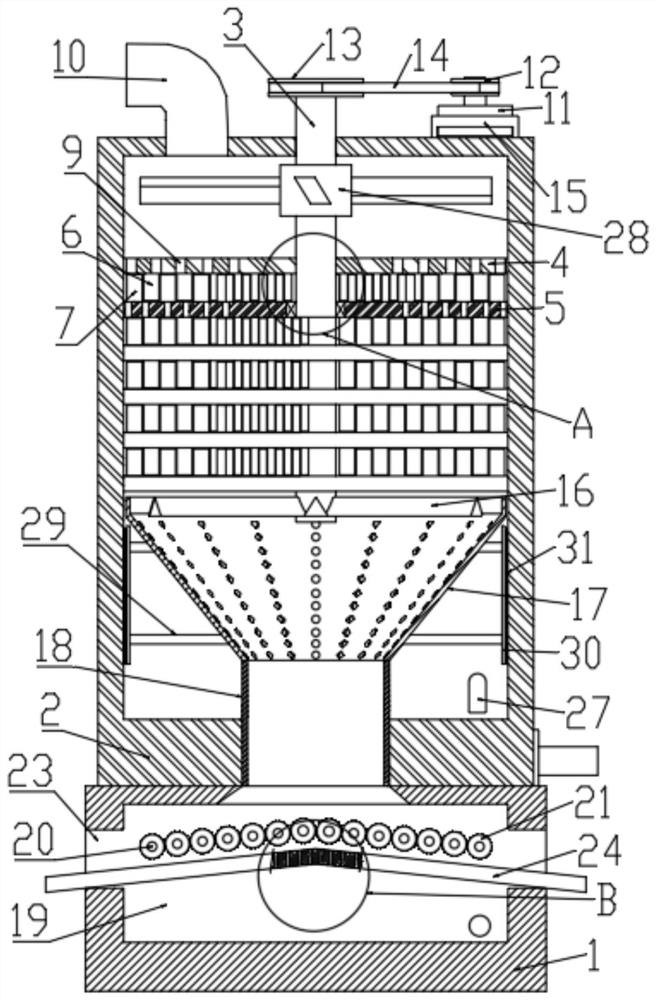

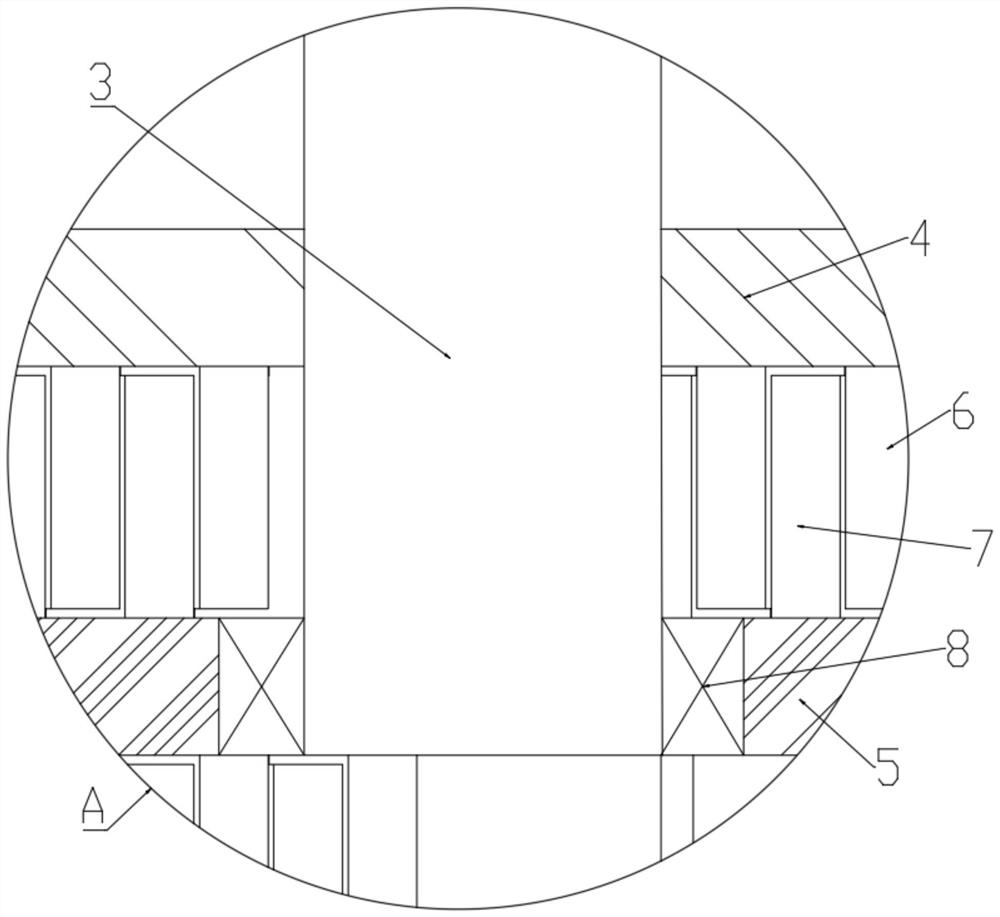

[0030] see Figure 1-6 , a high-quality and high-yield oil processing filter device, comprising a base 1, a cylinder 2 is fixedly installed on the upper surface of the base 1, a filter assembly is arranged in the cylinder 2, and the filter assembly includes a rotating shaft 3 and multiple groups of filter press components, filter press components Including a first filter plate 4, a second filter plate 5, a plurality of first pressure plates 6 and a plurality of second pressure plates 7, the rotating shaft 3 is vertically rotated and sleeved in the cylinder 2, and the first filter plate 4 is horizontally fixed and sleeved on the rotating shaft 3, the second filter plate 5 is horizontally fixed and sleeved in the cylinder body 2, and the middle part is rotatably connected with the rotating shaft 3 through the sealing bearing 8, and the plurality of first pressure plates 6 are vertically fixed and installed on the bottom surface of the first filter plate 4, and a plurality of The...

Embodiment 2

[0036] Embodiment 2: The difference based on Embodiment 1 is that a cavity 19 is opened in the base 1, and an extrusion part is arranged in the cavity 19. The extrusion part includes a plurality of rollers 20, a plurality of rolling wheels 21 and In the second motor 22, a plurality of rollers 20 are installed in the base 1 for horizontal and radial rotation, and a plurality of rolling wheels 21 are respectively fixed and sleeved on the plurality of rollers 20, and the two adjacent ones are in meshing contact, the second The motor 22 is horizontally and fixedly sleeved in the base 1 , and the output shaft is fixedly connected to the end of one of the rollers 20 through a coupling.

[0037] The left and right sides of the base 1 are provided with discharge ports 23 horizontally, and the two discharge ports 23 are connected to the cavity 19. A material guide plate 24 is horizontally arranged in the cavity 19. The material guide plate 24 is arched, and the front and rear two The e...

Embodiment 3

[0040] Embodiment 3: The difference based on Embodiment 1 is that two sets of cleaning parts are symmetrically arranged on the outside of the conical cylinder 17, and the cleaning parts include two connecting rods 29, scrapers 30 and a plurality of hairs 31, and two connecting rods 29 The squeegee 30 is fixed and installed horizontally on the side of the conical cylinder 17, the scraper 30 is vertically fixed and installed on one end of the two connecting rods 29 away from the conical cylinder 17, and the multiple hairs 31 are fixed horizontally and fixedly installed on the side of the scraper 30 away from the connecting rod 29, And one end away from the scraper 30 is in sliding contact with the inner wall of the cylinder 2 .

[0041] Under the centrifugal action, the oil is thrown out, and at the same time, the conical cylinder 17 drives the scraper 30 to rotate through the connecting rod 29, and the scraper 30 drives a plurality of filaments 31 to rotate, scraping off the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com