Method for internally arranging steel wire without exposure in manufacturing process of long and thin sand core

A production process and steel wire technology, applied in cores, manufacturing tools, casting molding equipment, etc., can solve problems affecting casting quality, steel wire exposure or offset, casting adhesion, etc., to reduce casting scrap rate, improve molding quality, Avoid the effect of excessive offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A method for embedding steel wires without exposure during the production of elongated sand cores, comprising the steps of:

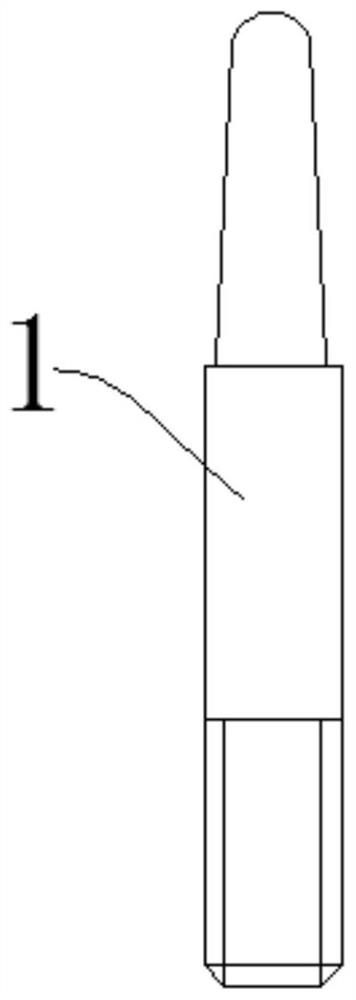

[0024] Step 1: Prefabricate three stepped hanging needles 1 according to the actual core making requirements;

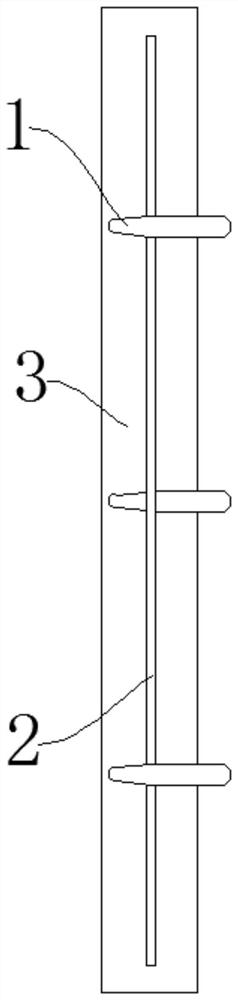

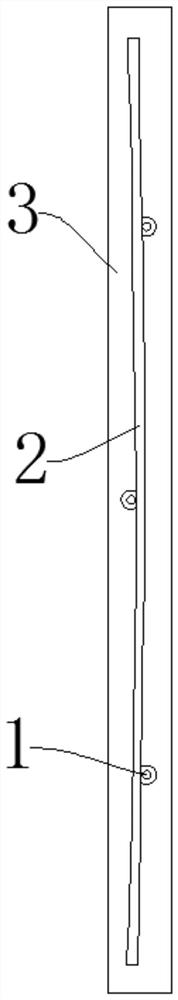

[0025] Step 2: Install the prefabricated hanging needles 1 in the core box cavity 3 in turn, and make the hanging needles 1 have a certain offset compared to the steel wire 2, so that the steel wire 2 can be squeezed more appropriately according to the needs, and the control Wire 2 position;

[0026] Step 3: The steel wire 2 that needs to be placed inside the sand core is in contact with the tapered end of the hanging needle 1 in turn, and the steel wire 2 is pre-pressed and fixed under its own elasticity by pressing;

[0027] Step 4: After the steel wire 2 is laid out, just inject the sand material for making the sand core into the core box cavity 3 and solidify it, and then the prefabrication of the sand core can be realized to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com