A kind of acupuncture needle automatic packaging device and packaging method

A technology for automatic packaging and acupuncture needles, which is applied in the directions of packaging, packaging protection, transportation and packaging, etc. It can solve the problems that the insertion depth of acupuncture needles cannot be guaranteed to be consistent, the positioning method is troublesome, and it is easy to cause pollution, so as to improve the packaging accuracy and packaging accuracy. Efficiency, simple structure, effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

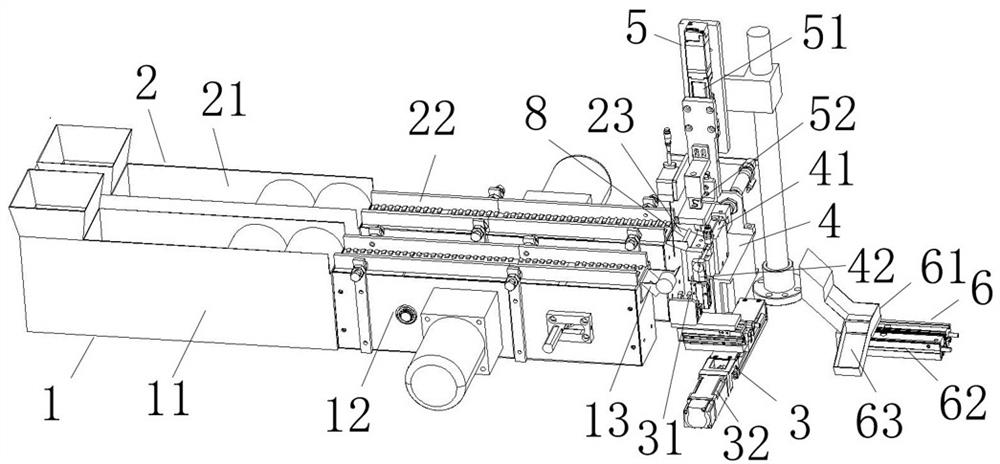

[0071] like figure 1 As shown, this embodiment relates to an automatic packaging device for acupuncture needles, which is used to pack a plurality of acupuncture needles 7 into a plastic tube 8, including acupuncture needle feeding device 1, plastic tube feeding device 2, needle insertion device 3 , packaging mechanism 4, detection device 5 and blanking device 6;

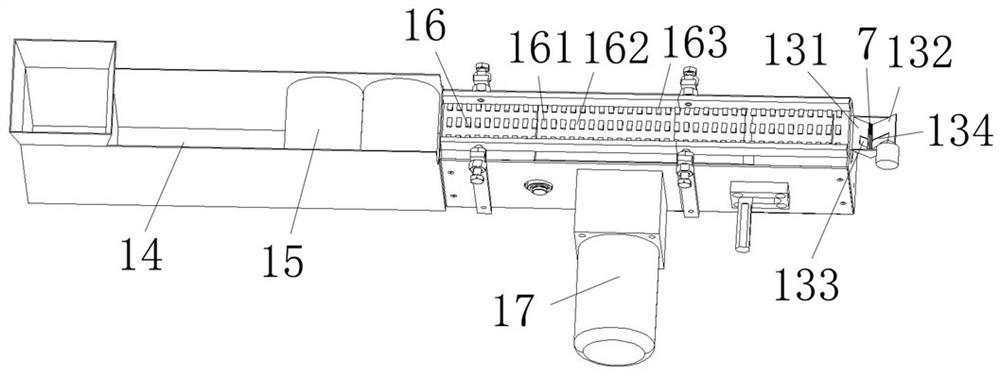

[0072] The acupuncture needle feeding device 1 includes a first silo 11, a first transmission line 12 and a hopper 13, the first silo 11 is located on one side of the first transmission line 12, and the hopper 13 is connected to the first transmission line 12. A side of the transmission line 12 that is far away from the first silo 11, the hopper 13 is provided with a clamping hole into which the pin insertion device 3 extends;

[0073] The plastic pipe feeding device 2 includes a second silo 21, a second transmission line 22 and a first guide groove 23, the second silo 21 is located on one side of the second transm...

Embodiment 2

[0107] This embodiment is performed on the basis of the above-mentioned first embodiment, and the same points as the above-mentioned embodiment will not be repeated.

[0108] The present embodiment relates to a packaging method, using the packaging device described in the first embodiment, which specifically includes the following steps:

[0109] S1, the first silo 11 separates the acupuncture needles 7 in sequence and inputs them into the first transmission line 12, and the acupuncture needles 7 are input into the hopper 13 through the first transmission line 12 and counted;

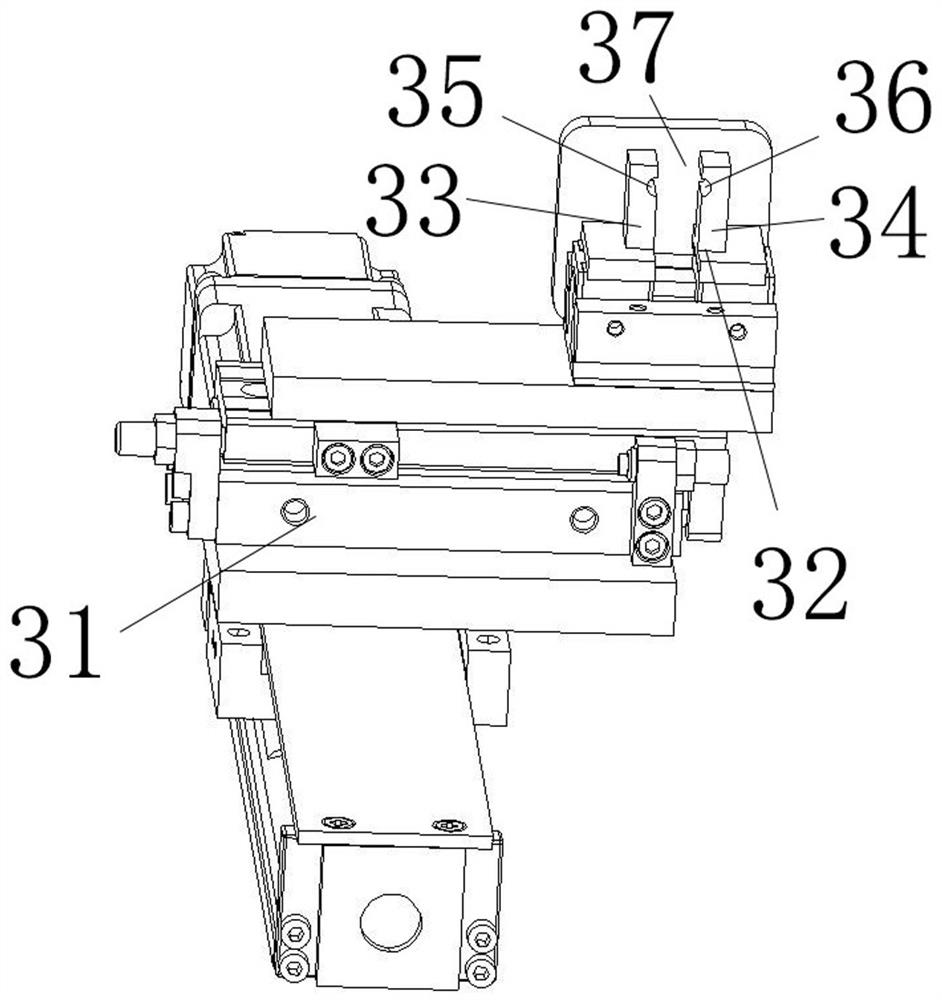

[0110] S2. When the number of acupuncture needles 7 in the hopper 13 reaches a specified number, the first moving mechanism 31 drives the clamping jaws 32 to move to the bottom of the hopper and inserts the clamping jaws 32 into the clamping holes to clamp the acupuncture needles 7, and then clamps the acupuncture needles 7. After the removal is completed, the clamping jaws 32 drive the acupuncture need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com