Solution system for automatically and circularly purifying and filtering liquid residues

An automatic circulation, liquid technology, applied in the direction of centrifugal separation of water/sewage treatment, etc., can solve the hidden dangers of parts and mold quality, reduce equipment service life, cold heading machine wear and other problems, achieve beautiful appearance, improve service life, improve The effect of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

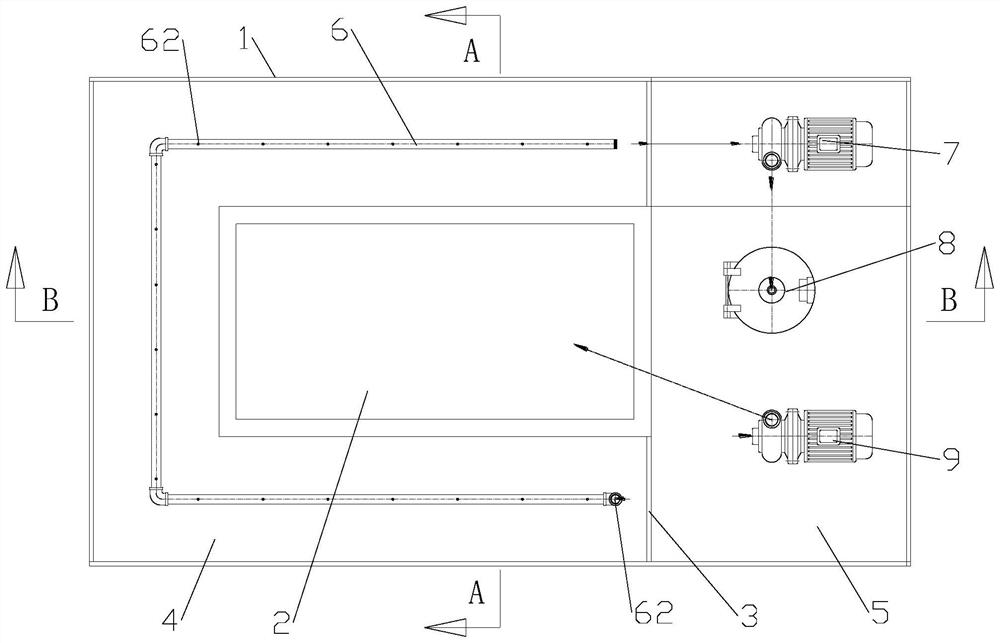

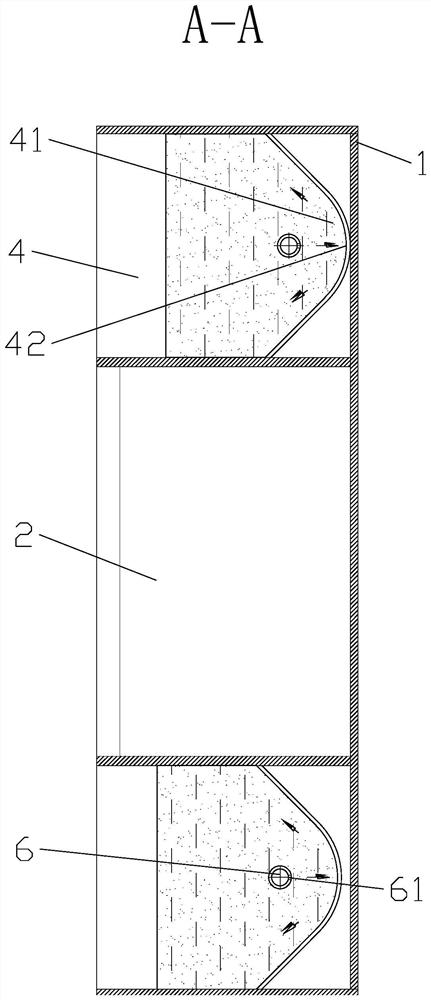

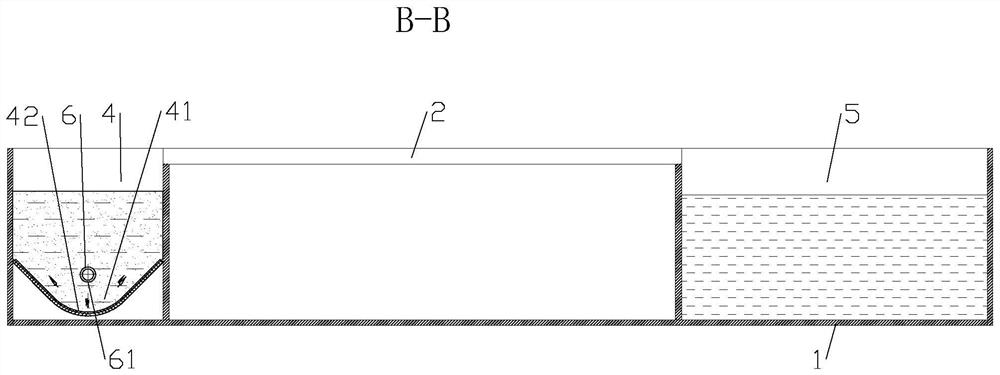

like Figure 1 to Figure 5 As shown, the present invention discloses a solution system for automatic circulation purification and filtering of liquid residues, including an oil pan 1, and a cold heading machine table 2 is arranged in the middle position of the oil pan 1, and the cold heading machine is placed on the cold heading machine. Work on the machine table 2, the oil pan 1 is provided with a partition 3, the partition 3 is connected with the cold heading machine table 2, and the partition 3 cooperates with the cold heading machine table 2 to The space in the oil pan 1 is divided into a dirty oil pool 4 and a clean oil pool 5. During the cold heading operation of the cold heading machine, the used cooling liquid flows into the dirty oil pool 4, and the oil pan 1 is provided with a cooling liquid Filter mechanism, a boiling pipe 6 is provided in the dirty oil pool 4, and a number of exhaust holes 61 are provided on the boiling pipe 6, and these exhaust holes 61 are all arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com