Preparation method of long-acting anti-aging material

An anti-aging, long-acting technology, applied in the field of rubber additives, can solve the problems of loss of protective rubber macromolecules, environmental pollution of anti-aging materials, etc., achieve the effect of inhibiting free radical reaction and improving heat resistance

Pending Publication Date: 2022-06-03

常州市五洲化工有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The general anti-aging material added to rubber by mixing will be extracted under the conditions of use of rubber products and lose the function of protecting rubber macromolecules, and the escaped anti-aging material will pollute the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

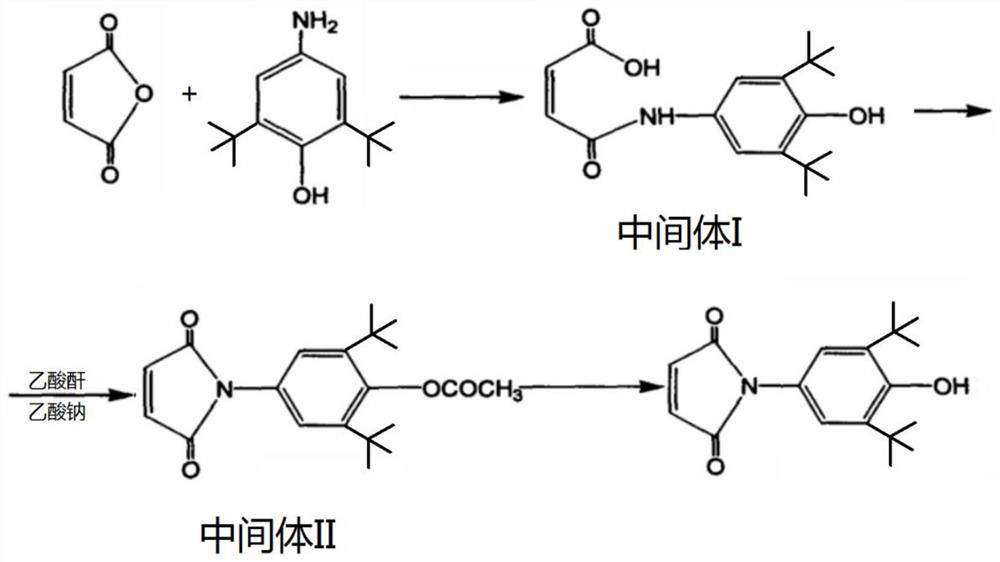

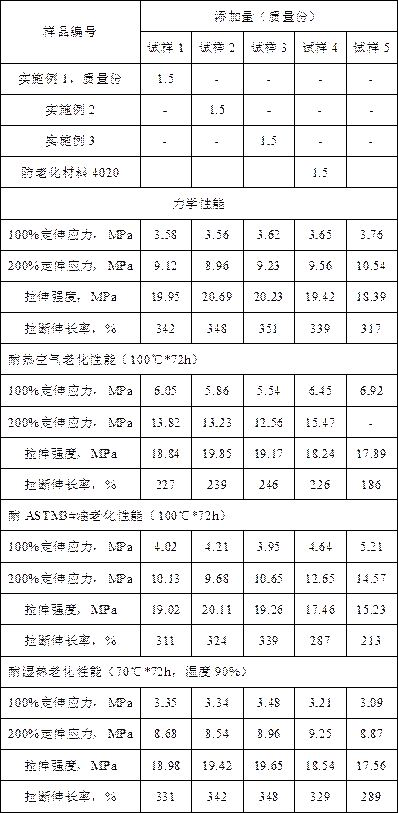

The invention discloses a preparation method of a long-acting anti-aging material, which comprises the following specific preparation steps: S1, preparing 2, 6-di-tert-butyl-4-nitrosophenol; s2, preparing 2, 6-di-tert-butyl-4-aminophenol (2, 6- S3, preparing an intermediate I; s4, preparing an intermediate II; and S5, dissolving the intermediate II in absolute methanol, adding a catalyst p-toluenesulfonic acid, carrying out reflux reaction for 6-8 hours, distilling methanol / methyl acetate azeotrope under normal pressure, and recrystallizing in isopropanol to obtain the phenolic hydroxyl group-containing maleimide. The rubber vulcanizing agent contains an active group maleic double bond capable of reacting with rubber macromolecules, can chemically react with rubber in the vulcanizing process, is bonded in a rubber macromolecular network through a chemical bond, and has the advantages of no migration, no volatilization and no extraction; meanwhile, phenolic hydroxyl groups with the function of inhibiting rubber aging are provided, substances harmful to human bodies cannot be generated, and Ror ROO generated in aging reaction is easily captured, so that free radical reaction is inhibited, and the purpose of preventing rubber aging is achieved.

Description

technical field [0001] The invention belongs to the field of rubber auxiliaries, and relates to a preparation method of a long-acting anti-aging material. Background technique [0002] During the use of rubber, it will be affected by external factors (such as ozone aging, thermal oxygen aging, etc.) and age, resulting in changes in its physical and mechanical properties, causing the rubber to lose its elasticity, decrease its mechanical properties, and shorten its service life. In order to solve the problem of rubber aging, it is necessary to add anti-aging materials to the rubber in order to inhibit or delay the aging process and prolong the service life of rubber products. [0003] The general anti-aging material added to the rubber by kneading will be drawn out under the use conditions of the rubber product and lose the function of protecting the rubber macromolecules, and the escaped anti-aging material will pollute the environment. Therefore, the development of anti-ag...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07D207/452C08K5/3415C08L9/02

CPCC07D207/452C08K5/3415C08L9/02C08L2201/08

Inventor 方春平方韬唐英俊

Owner 常州市五洲化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com