Method for blowing steel ladle top slag modifier by using CO2

A technology for ladle top slag and CO2, applied in the field of iron and steel smelting, can solve the problems of high production cost of ladle top slag modifier, affecting the normal refining of molten steel, difficulty in driving a spray gun, etc., so as to improve dynamic conditions, reduce waste of resources and environment. Pollution, to ensure the effect of normal refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

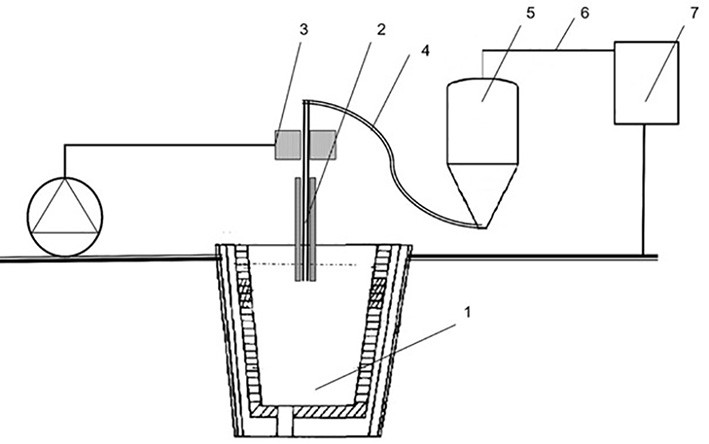

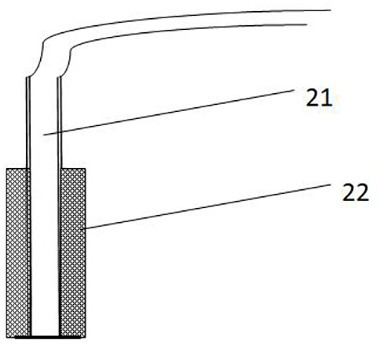

The invention is applied to the upgrading of 60-ton converter ladle top slag in a factory, the average tapping volume is 60 tons, the test steel grade is HPB300, and the limestone powder with a particle size of 0-20 mm after being sieved, and the solid waste produced by an electrolytic aluminum factory The aluminum ash is crushed to a particle size between 0 and 20 mm, and then the above limestone powder ore and aluminum ash are ball-milled to a particle size of less than 1 mm. %, Al 2 O 3 : 15% to 25%, mechanically mix it and add it to the powder silo 7. After the converter is tapped, the ladle 1 is transported to the bottom of the top blowing lance 2, the lift control system 3 on the upper part of the top blowing lance is driven, the top blowing lance 2 is lowered and inserted into the ladle 1 5-50 mm below the top slag level, and the top is lowered. Turn on the carrier gas while blowing the spray gun 2 to prevent the top blowing spray gun 2 from being blocked. After the to...

Embodiment 2

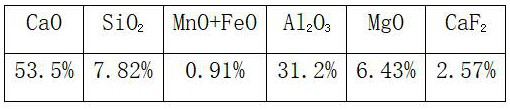

The invention is applied to the upgrading of 180-ton converter ladle top slag in a factory, the average tapping amount is 195 tons, the test steel grade is HRB400E, and the top slag composition after tapping is shown in the following table:

The sieved limestone powder with a particle size of 0-20mm and the solid waste aluminum ash produced by an electrolytic aluminum plant are crushed to a particle size of 0-20mm, and then the above limestone powder ore and aluminum ash are ball-milled to a particle size of less than 1mm. , the components are calculated in mass percentage, CaO: 40% to 50%, Al: 30% to 50%, Al 2 O 3 ≤10%, SiO 2 ≤4%, mix it mechanically and add it to powder silo 7. After the converter is tapped, the ladle 1 is transported to the bottom of the top blowing lance 2, the lift control system 3 on the upper part of the top blowing lance 2 is driven, the top blowing lance 2 is lowered and inserted into the ladle 1 5-50 mm below the top slag liquid level, and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com