Top plate transverse stiffening type corrugated steel web combined box girder

A corrugated steel web, combined box technology, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of large amount of engineering materials, hindering the development of large span of bridge structure, lightweight direction, and self-heavy weight, etc. Shear resistance, superior structural stress and construction performance, and the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and embodiments.

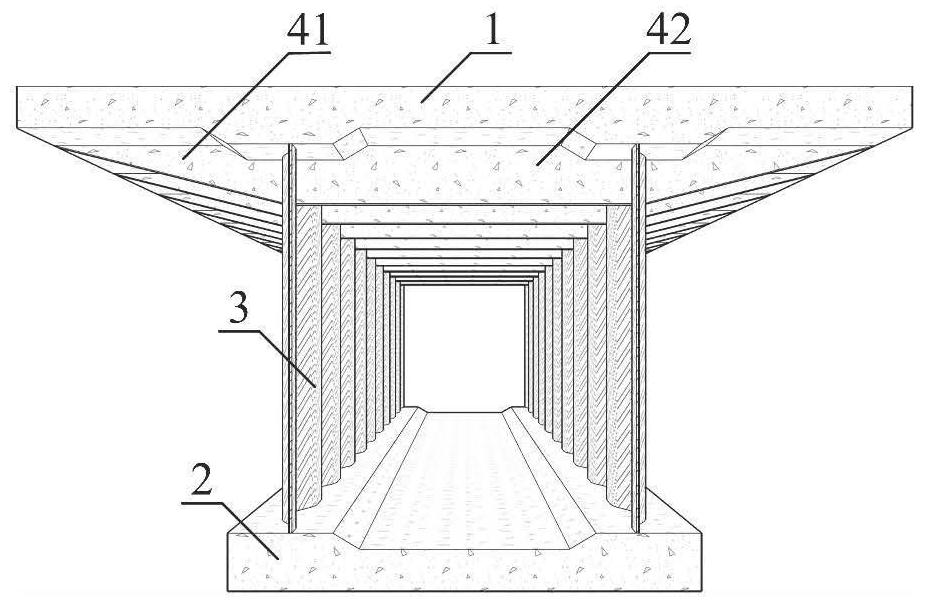

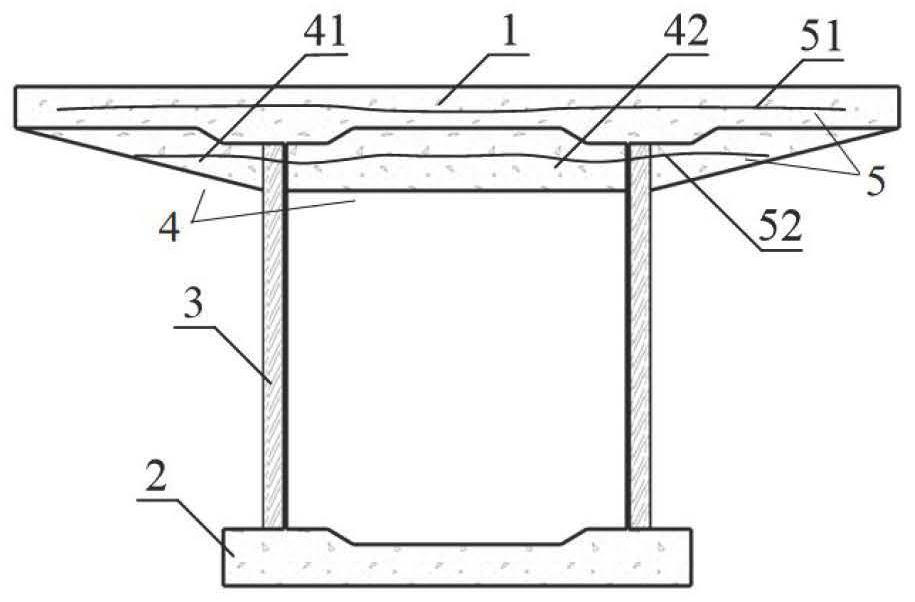

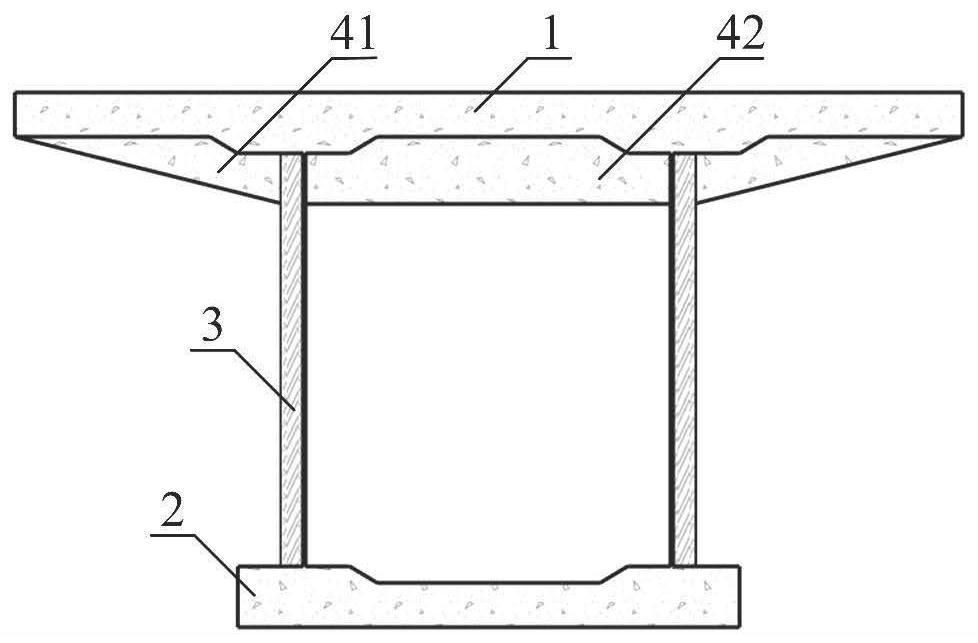

[0031] A roof transversely stiffened corrugated steel web composite box girder, comprising a concrete top plate 1, a concrete bottom plate 2, a corrugated steel web 3, a concrete transverse stiffener 4, a transverse prestressed steel bundle 5, a longitudinal joint steel bar 6, and a transverse penetration steel bar 7, stud key 8; the corrugated steel web 3 is composed of straight plate section 31, inclined plate section 32 and arc section 33; the concrete transverse stiffener 4 is composed of the outer transverse stiffener 41 of the web and the web The inner transverse stiffener 42 is composed; the transverse prestressed steel bundle 5 includes the transverse prestressed steel bundle 51 in the top plate and the transverse prestressed steel bundle 52 in the transverse stiffener;

[0032] The concrete top plate 1 , the concrete bottom plate 2 and the corrug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com