Multi-layer module interconnection integrated cabinet for electronic equipment

A technology of electronic equipment and multi-layer modules, which is applied to the structural parts of electrical equipment, electrical components, circuit layout on the support structure, etc., can solve the problems of narrow cabin space, complex cabinet structure, and large number of wires, etc. It achieves the effects of convenient installation and maintenance, stable and reliable geometric structure, improvement of internal space utilization and maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

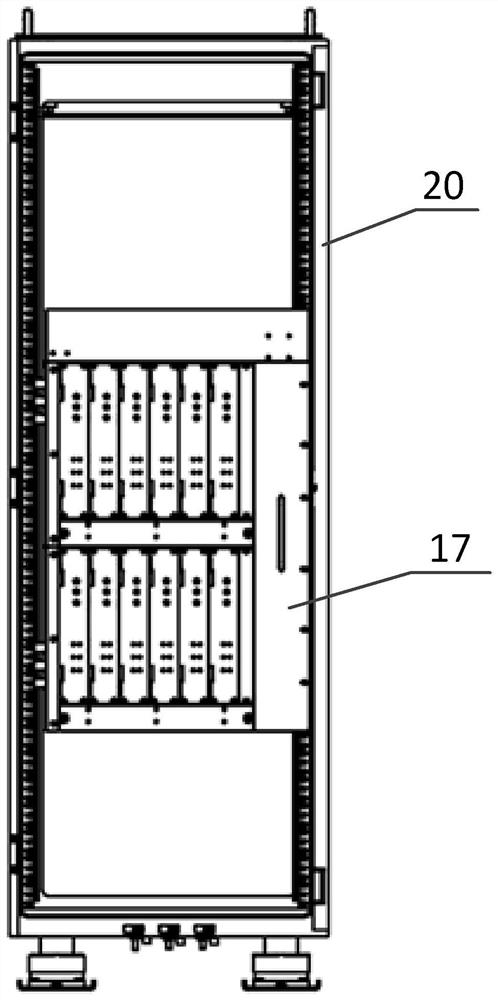

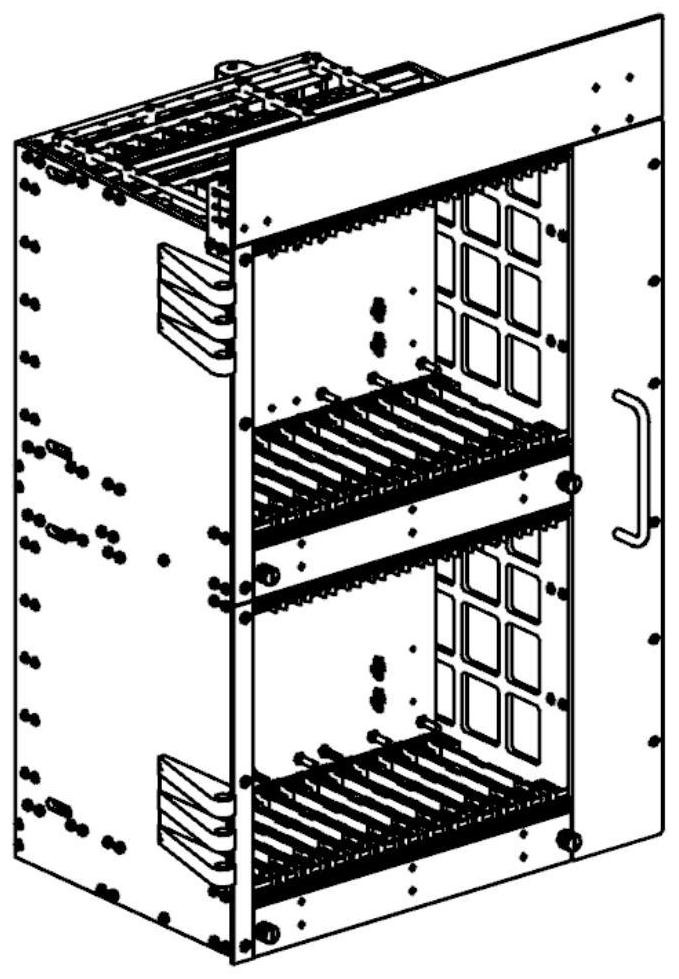

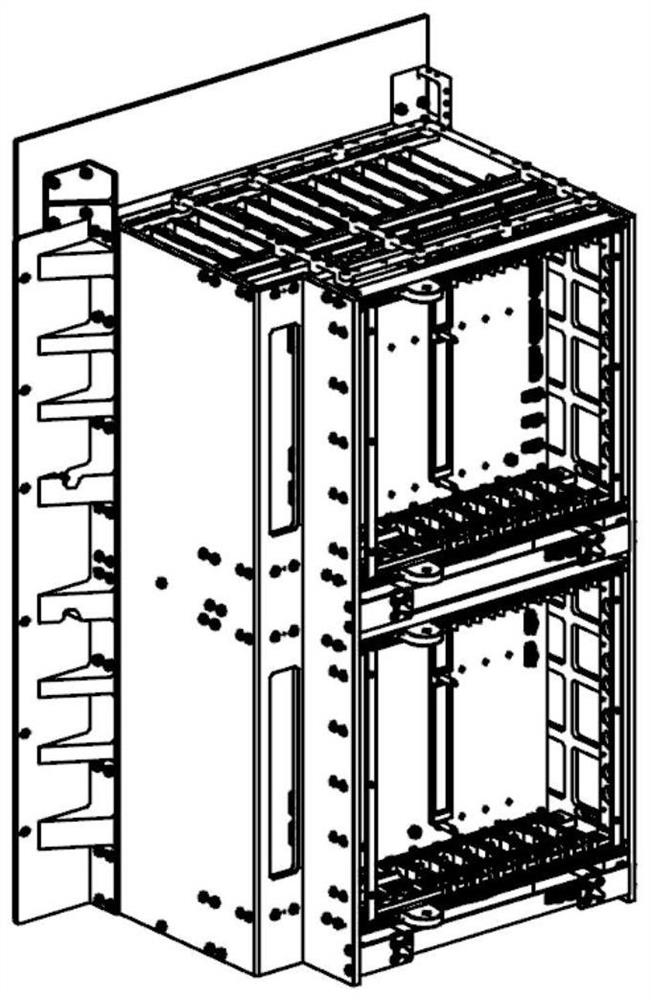

[0014] see Figure 1-Figure 5. In the following embodiments, a multi-layer module interconnection integrated cabinet for electronic equipment includes: a left side panel 12, a right side panel 11, a rear beam 3, a middle beam 4, a beam 5, a front beam 6, installation accessories and each The multi-layer interconnected rotating storage rack and integrated heat dissipation mechanism composed of the layer fan assemblies 15, the cabinet cabinet 20 carrying the internal storage racks and cables of the electronic equipment, wherein: the middle and bottom of the rotating storage rack are provided with at least two layers of fan assemblies 15, the same The front and rear plug-in modules of each layer are connected to the same printed board 9 through connectors to realize interconnection, and the sockets of printed board 9 connect cables to realize external connection. Or converge upwards to the top cable tie frame 2. After the top cable tie frame 2 is assembled, it is bundled to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com