Composite modified starch and production method thereof

A technology for compounding modified starch and production method, which is applied in the fields of climate change adaptation, food ingredients as taste improvers, food ingredients as humectants, etc. Taste and other issues, to achieve the effect of enriching nutrients, enhancing human immunity, and improving the taste of meat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

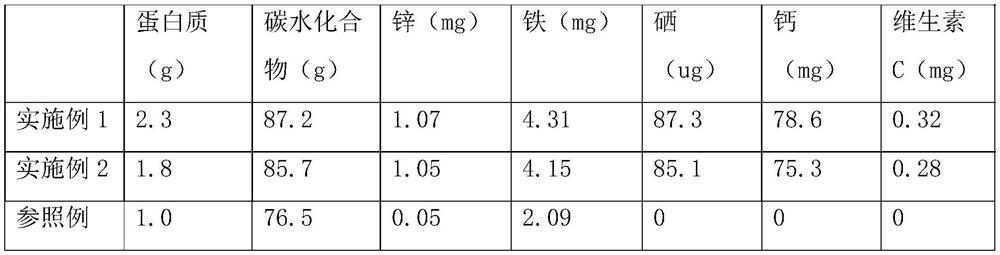

Examples

Embodiment 1

[0020] In the embodiment of the present invention, a composite modified starch includes the following materials in parts by weight: 65 parts of mixed raw starch, 0.25 parts of trace elements, 2 parts of etherifying agent, 2 parts of cross-linking agent, 0.8 part of lye regulator, acid solution Conditioner 0.8 parts, deionized water 23 parts.

[0021] Further, a kind of production method of composite modified starch, comprises following concrete steps:

[0022] S1: put the mixed raw starch into a mixer, add deionized water and stir to form a slurry with a concentration of 40-42wt%;

[0023] S2: adjust the pH of the slurry to 9-10 by an alkali liquor regulator, and then add an etherifying agent to carry out etherification reaction;

[0024] S3: The pH of the etherified slurry is adjusted to 7-8 by an acid solution regulator, and a cross-linking agent is added for cross-linking reaction until the viscosity reaches 600-800BU;

[0025] S4: After washing the slurry obtained in S3,...

Embodiment 2

[0031] It is prepared completely according to the scheme of Example 1, and what is different from Example 1 is: a composite modified starch, including the following materials in parts by weight: 60-70 parts of mixed native starch, 0.1-0.3 parts of trace elements, 1- 3 parts, 1-3 parts of crosslinking agent, 0.5-1.0 part of lye regulator, 0.5-1.0 part of acid solution regulator, 15-25 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com