Positioning fixture and processing method for rotor cover of gyro motor dynamic pressure air bearing

A technology for positioning fixtures and rotor covers, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as scratches, poor positioning accuracy, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

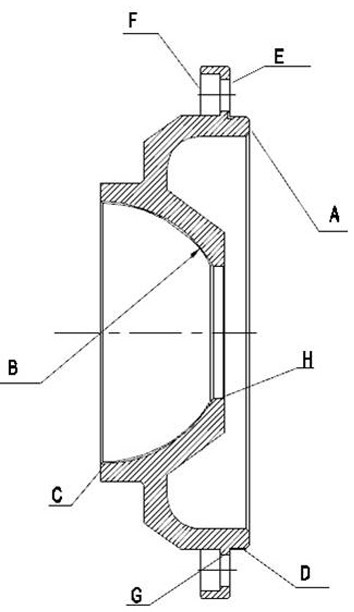

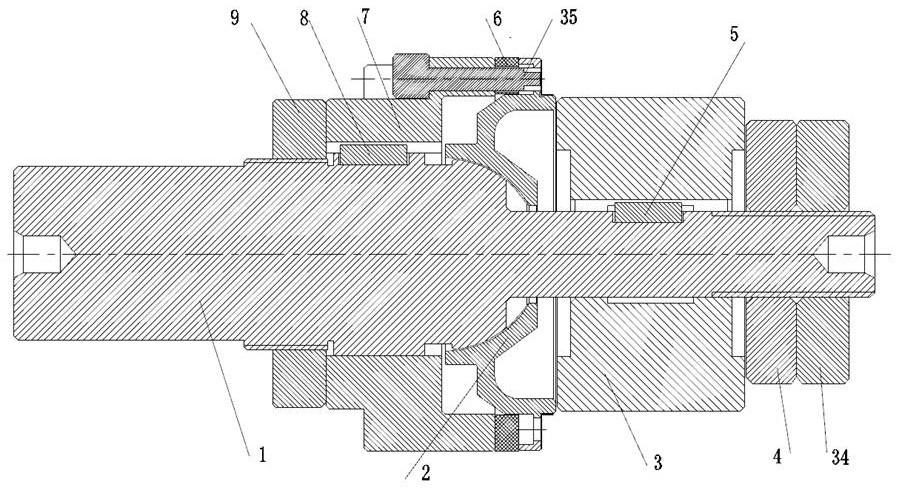

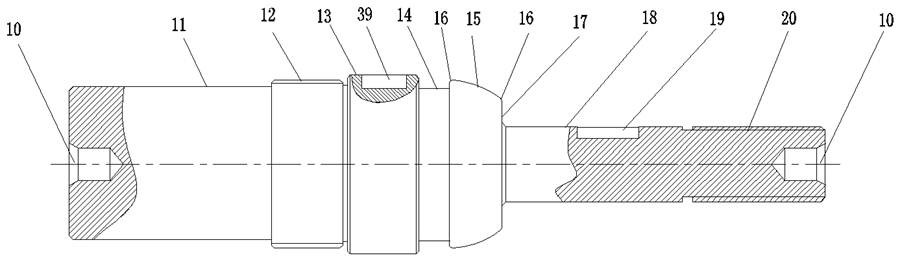

[0063] see Figure 2 to Figure 7 , Gyro motor dynamic pressure air bearing rotor cover positioning fixture, including spherical positioning mandrel 1, positioning collar 3, second flat key 5, compression nut 4, anti-loosening nut 34, vibration damping pad 6, positioning pin 35, back To the support seat 7, the first flat key 8 and the lock nut 9; the spherical positioning mandrel 1 is a coaxially arranged step shape, including a clamping section 11, a large thread section 12, a second guide cylindrical section 13, a first Four keyway 39, ring groove section 14, spherical positioning section 15, ball table end surface 17, first guide cylindrical section 18, first keyway 19 and small thread section 20; high-precision top holes are machined at both ends of spherical positioning mandrel 1 10. It is used to adopt the positioning method of two tops on the machine tool; the clamping section 11 is used to install the fork to drive the rotation of the spherical positioning mandrel 1 thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sphericity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com