Multi-friction contact surface nonlinear vibration absorption-energy consumption device for momentum wheel

A technology of energy-consuming devices and contact surfaces, which is applied in the direction of aerospace vehicle guides, motor vehicles, transportation and packaging, etc., can solve the problem of small number of friction contact surfaces, small relative movement of vibration-damping shrapnel, and hysteresis energy consumption effect of dry friction To achieve the effect of high efficiency dry friction hysteresis energy consumption and strong load adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] To make the technical solution and main points of the present invention more clear, the following will be combined Figure 1-Figure 8 and specific examples for a complete description of the invention.

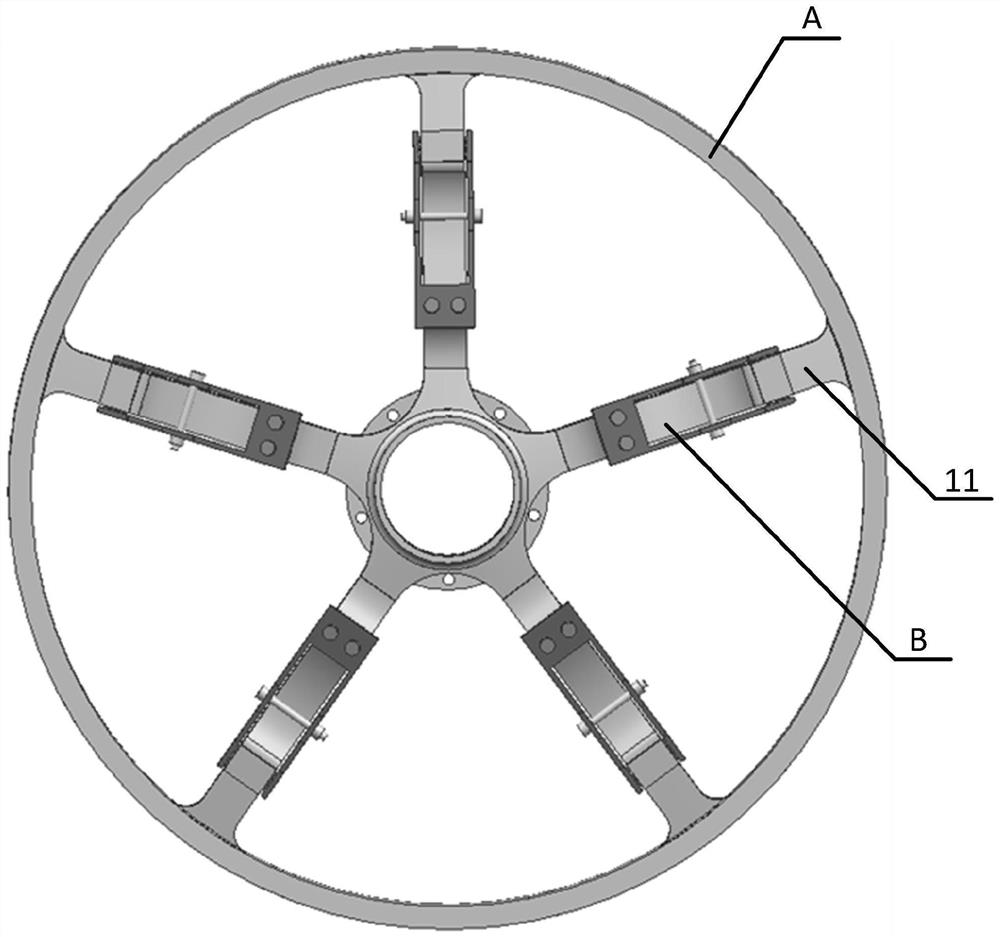

[0035] as Figure 1 As shown, the present invention discloses a multi-friction contact surface for the momentum wheel nonlinear vibration absorption - energy consumption device, the multi-friction contact surface nonlinear vibration absorption - energy consumption device B is mounted on the momentum wheel spokes 11 of the momentum wheel A, for absorbing - dissipating the vibration energy of the momentum wheel A, reducing its vibration response, to ensure the pointing accuracy, attitude stability and imaging quality of the spacecraft platform.

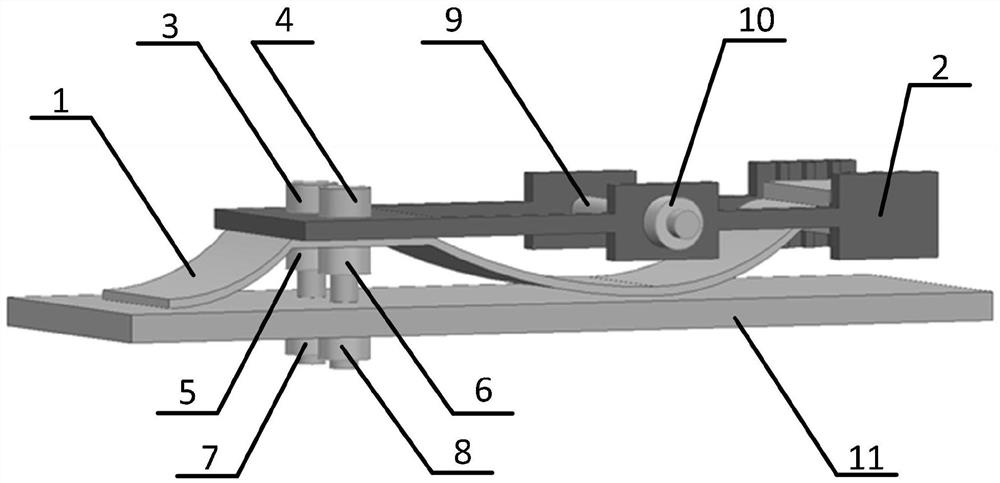

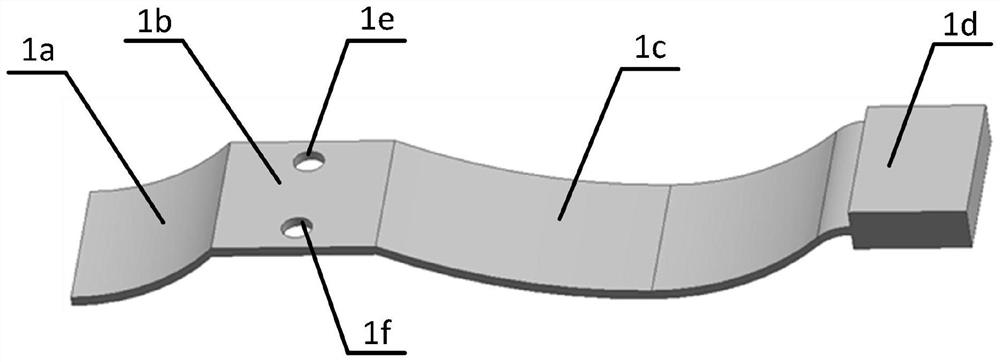

[0036] as Figure 2As shown, a single multi-friction contact surface nonlinear vibration absorption - energy dissipation device B comprises a vibration damping shrapnel 1, an auxiliary bracket 2, a first mounting bolt 3, a second mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com