An arched self-supporting formwork for tunnel concrete construction and pouring

A concrete and self-supporting technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of trolley loading and unloading, complicated installation, difficult transportation, occupying construction space, etc., and achieves fast and convenient transfer, simplified formwork structure, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the objectives, technical solutions and advantages of the present invention clearer, the invention will be clearly and completely described below with reference to specific embodiments.

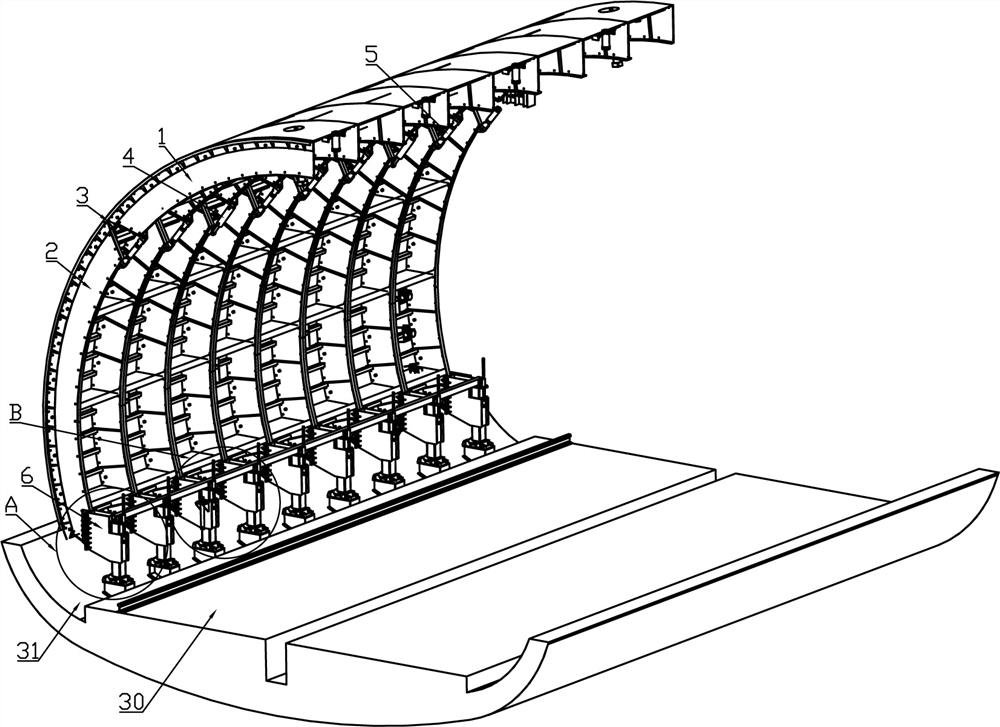

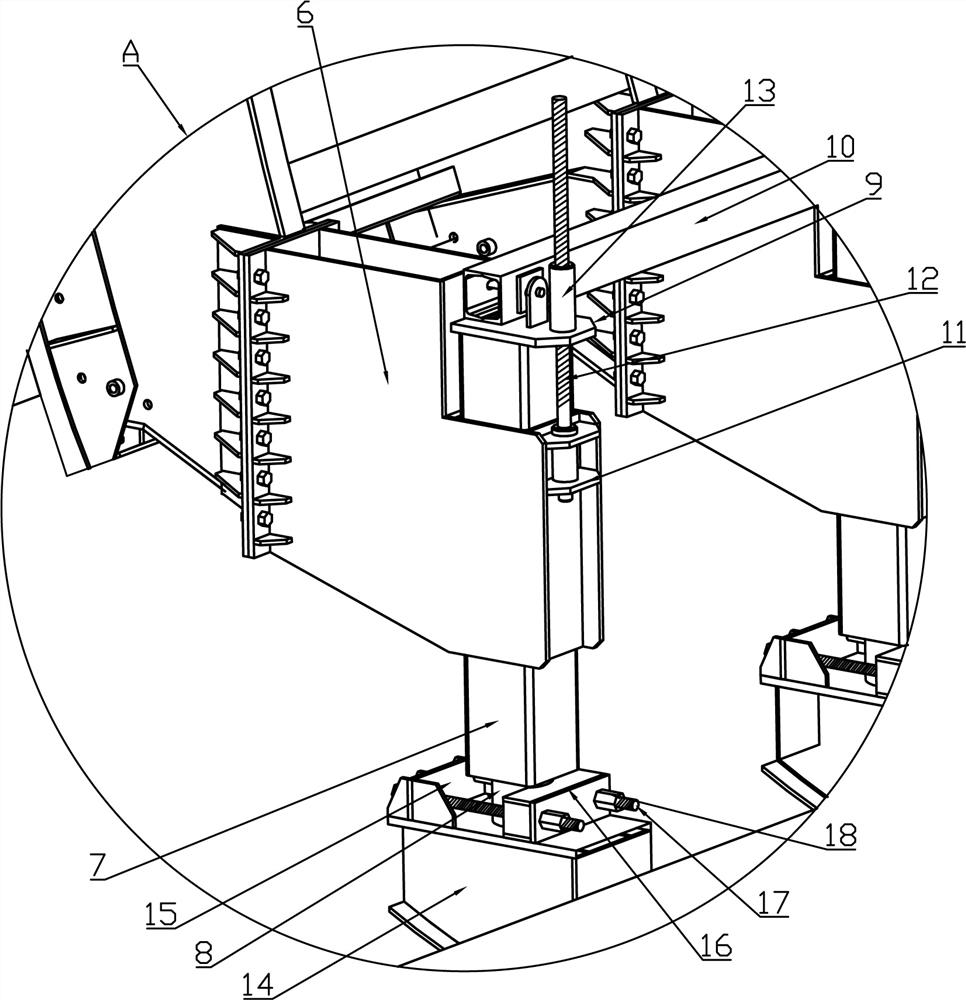

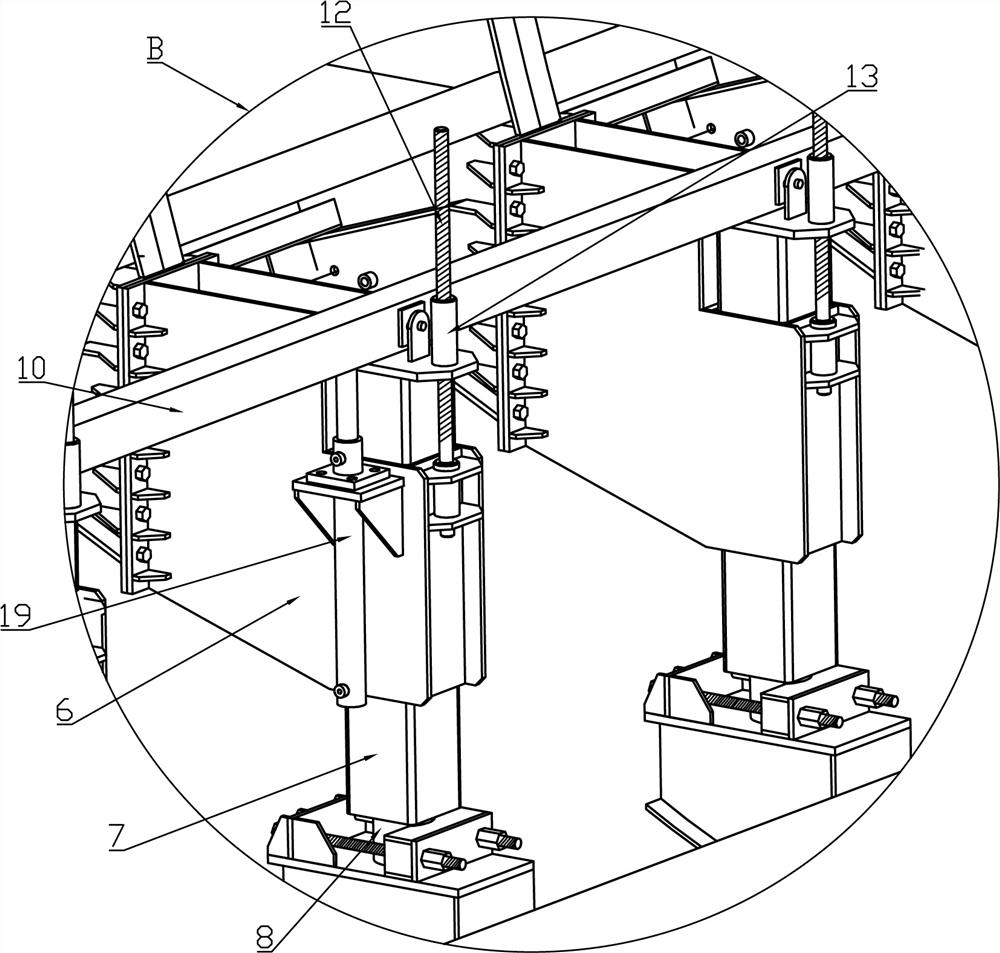

[0034] like Figure 1-Figure 3 , Figure 10 and Figure 11 The shown arched self-supporting formwork for tunnel concrete construction and pouring comprises an arcuate upper formwork 1 and an arcuate lower formwork 2 hinged with its left and right ends through a hinge shaft 3. The upper formwork 1 A plurality of hydraulic rods 1 4 and a plurality of brace rods 5 are arranged at the hinge joint with the lower formwork 2, and the two ends of the hydraulic rod 1 4 and the brace rod 5 are hinged with the lower part of the upper formwork 1 and the upper part of the lower formwork 2 respectively. ; The upper formwork 1 and the lower formwork 2 are evenly provided with a plurality of pouring windows. like figure 1 As shown, the upper die plate 1 and the lower die plate 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com