Ocean equipment underwater test device and operation method thereof

A technology of marine equipment and test device, applied in the field of marine equipment underwater test device, can solve the problems of high test cost, single function and high cost, and achieve the effects of wide function expansion space, convenient transportation conditions and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Autonomous underwater vehicle (AUV) underwater deployment recovery test:

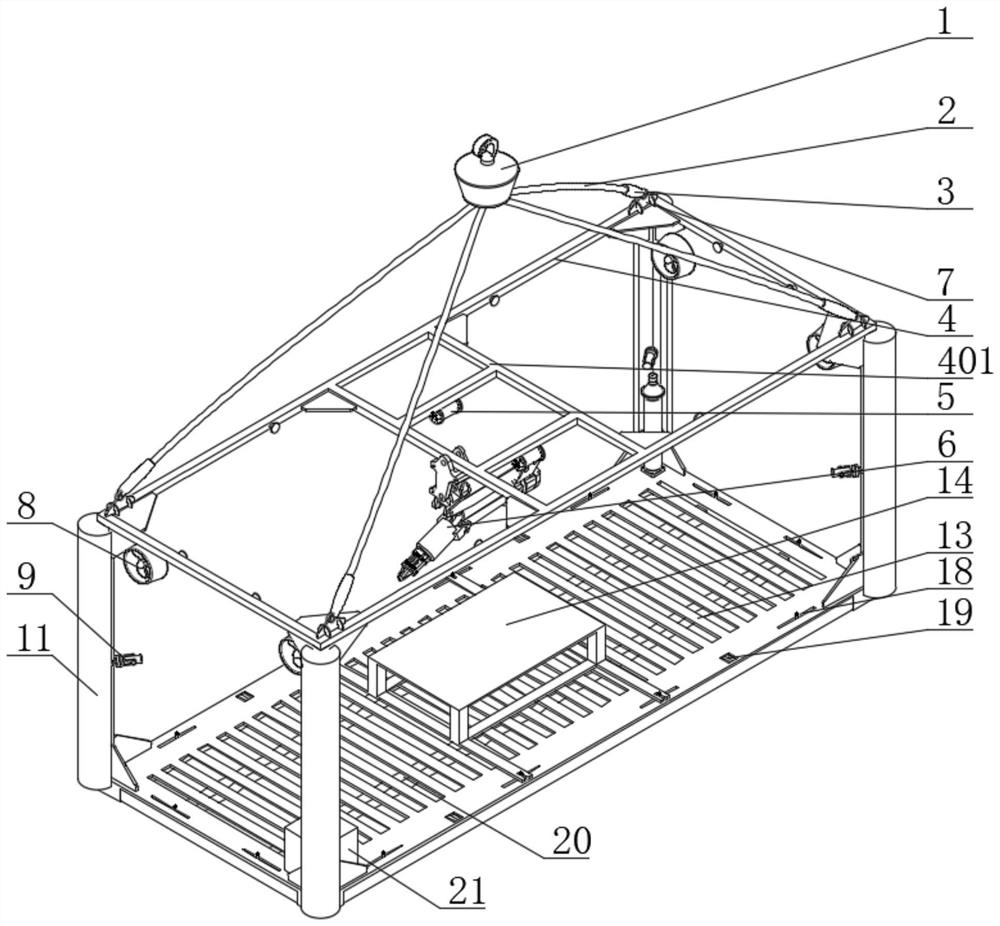

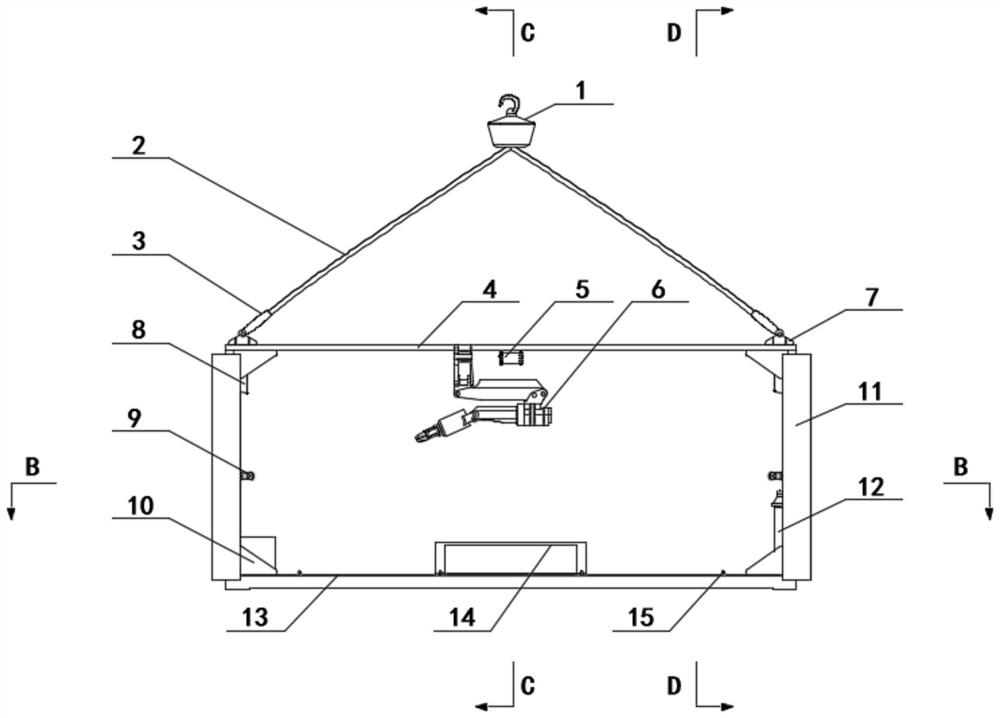

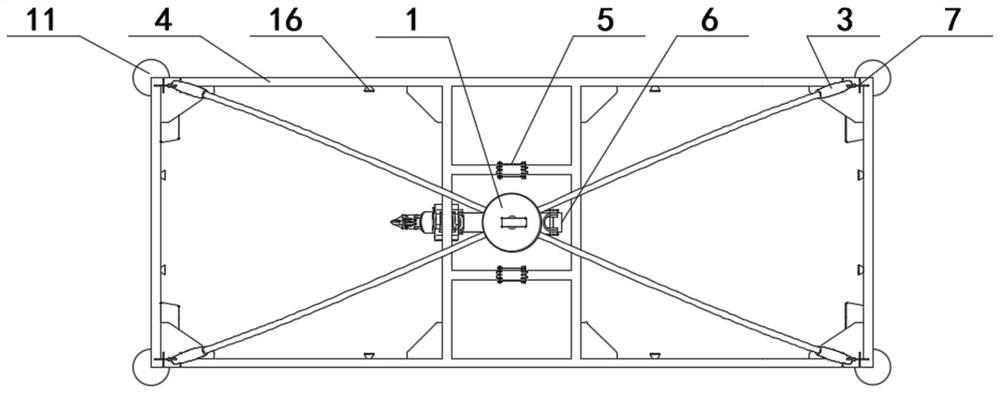

[0067] Land transportation: make full use of the main frame module designed by the standard container size of this test device (lifting main crane 1, steel structure frame 4, auxiliary crane 7, bracket 10, anti-collision rubber 11, plank grille 13, square pipe 20) and other modularly designed test auxiliary modules, dynamic positioning modules and test data acquisition modules, which are transported by container trucks on land to the loading dock;

[0068] Ship loading operation and voyage: After land transport to the loading dock, the integration and debugging of the main frame module, test auxiliary module, dynamic positioning module and test data acquisition module of the test device are completed. Among them, the composite cable bearing head 3 is used for The connection between the photoelectric composite armored cable 2 and the auxiliary crane 7 is lifted to the designated area on the test m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com