Production line and method for automobile radar processing

An automotive radar and production line technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to increase the scope of application, high clamping efficiency, and achieve the effect of secondary detection and judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

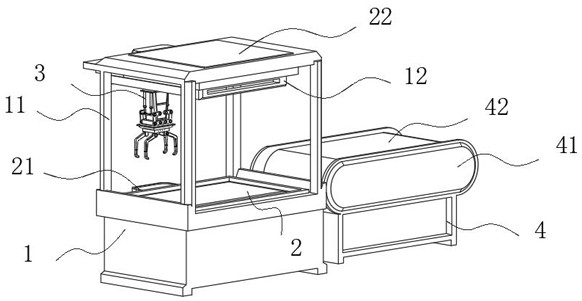

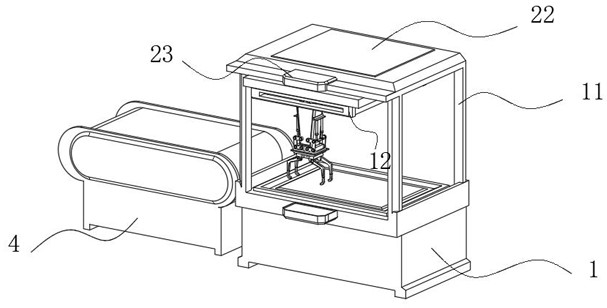

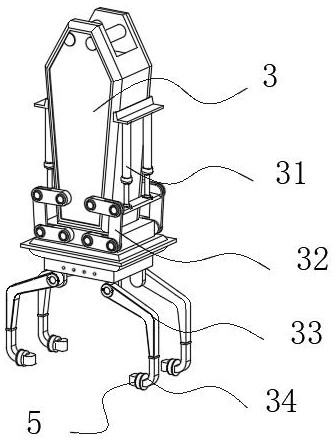

Embodiment 1

[0031] It is worth noting that after the automotive radar equipment emits electromagnetic wave signals, if a target object touches the radar signal, it will reflect the echo, and the radar receiver will receive the echo signal. The echo signal contains the distance, direction and speed information of the target. , the radar antenna receives the reflected wave and sends it to the receiving device for processing, extracts some information about the object, and can also measure the angle of the target according to the radar emission beam. This part acts as the main principle of the automotive radar, and the automotive radar accessories Including the built-in circuit board structure and the shell bracket structure, both can use the clamping structure to carry out joint clamping processing, and the manipulator 3 clamps and assembles the automotive radar accessories and moves them to another assembly platform, so the track of the sliding bracket 12 The restriction is not only applied...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com