Burning furnace air supply control method based on variable period prediction of hot blast stove

A control method and technology for hot blast stoves, which are applied in non-electric variable control, knowledge-based model computer systems, temperature control, etc., to achieve the effects of ensuring stability, saving gas, and adjusting strategies accurately

Active Publication Date: 2022-06-10

科大智能物联技术股份有限公司 +1

View PDF15 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

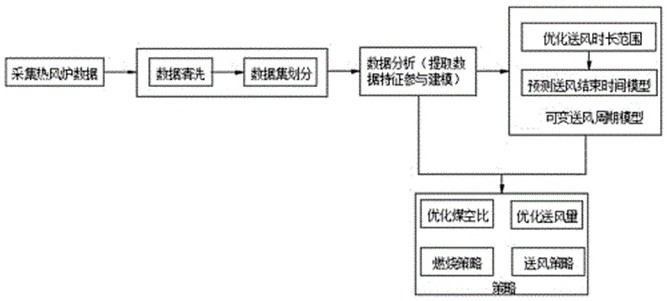

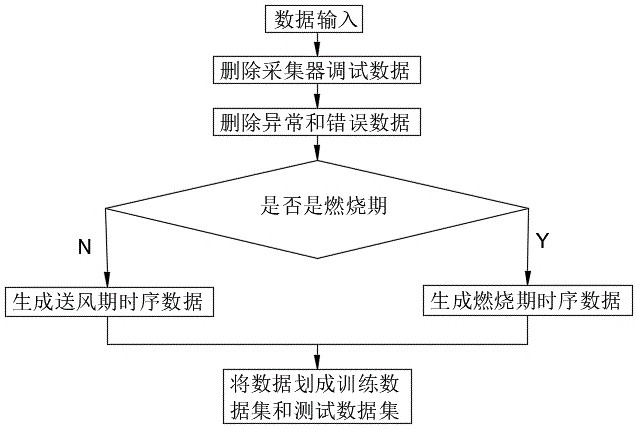

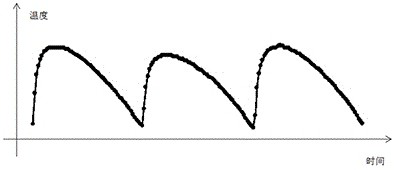

(1) How to predict the end time of air supply by constructing a variable air supply cycle model, and also determine the combustion cycle of the combustion furnace at the same time, so as to ensure the temperature of the air supply when supplying air to the blast furnace, and make full use of the previous production process The data of the combustion cycle and the air supply cycle are calculated and processed to achieve the effect that the air supply cycle and the combustion cycle can be changed according to the actual combustion situation, and solve the problem of low air supply temperature and low temperature caused by the fixed combustion cycle and air supply cycle mechanism in the prior art. The problem of large temperature fluctuations;

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a combustion furnace air supply control method based on hot blast stove variable period prediction. The method comprises the steps of obtaining and preprocessing historical data, building a variable air supply period model and generating a combustion strategy of a variable combustion period. By constructing a variable air supply period model, the air supply ending duration is predicted, the air supply temperature is guaranteed when air is supplied to the blast furnace, meanwhile, data of a combustion period and an air supply period in the previous production process are fully utilized for calculation processing, and the air supply period and the combustion period can be adjusted and changed according to the actual furnace combustion and air supply conditions; the limit values of the traditional fixed combustion period and the air supply period are broken through; the data of the combustion period and the air supply period are used as input variables for linkage analysis, the combustion strategy of the combustion period and the air supply strategy of the air supply period are correspondingly generated according to the analysis result, the temperature and the stability in the combustion and air supply process are guaranteed, the furnace is burnt by adopting the optimal coal gas-combustion air ratio, sufficient coal gas combustion is guaranteed, and the combustion efficiency is improved. And resource waste is avoided.

Description

technical field [0001] The invention relates to the technical field of blast furnace smelting, and specifically relates to a furnace air supply control method based on variable cycle prediction of hot blast furnaces. Background technique [0002] In the blast furnace ironmaking process, a large amount of combustion-supporting air needs to be injected into the blast furnace to promote the ironmaking reaction in the blast furnace. Because the internal temperature of the blast furnace is very high, the injection of normal temperature air will cause the temperature in the blast furnace to drop rapidly, which is not conducive to ironmaking. For the reaction to proceed, it is necessary to inject high-temperature air. The function of the hot blast stove is to heat the low-temperature combustion-supporting air to a high temperature. The working cycle of the hot blast stove is divided into a combustion period and an air supply period. [0003] Among them, the combustion period is ma...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G05D23/20C21B9/00G06N3/04G06N3/08G06N5/00

CPCG05D23/20C21B9/00G06N3/084C21B2300/04G06N5/01G06N3/044

Inventor 王筱圃张永强张庆张弢钟智敏陈波

Owner 科大智能物联技术股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com