Efficient cooling equipment for manufacturing industrial automatic control system device

An automatic control system and high-efficiency technology, applied in the construction of electrical equipment parts, cooling/ventilation/heating transformation, separation methods, etc., can solve the problems of integrated circuit component damage, inclusion, and potential safety hazards, and achieve high water absorption. Improve drying efficiency and avoid accumulation

Pending Publication Date: 2022-06-21

深圳市凌心科技有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Due to the large number of integrated circuit components, control components, and human-computer interaction components in the integrated cabinet, a large amount of heat will be generated during the operation of the integrated cabinet. By drawing the cold air from the outside into the integrated cabinet, the temperature of the integrated cabinet can be effectively realized through the exchange of cold and heat. However, there is water vapor in the air, and the water vapor content is different in different seasons. When the water vapor enters the integrated cabinet, it will condense into water droplets. Water droplets It will cause damage to integrated circuit components, control components, and human-computer interaction components, and the installation will cause safety hazards. Therefore, the present invention proposes a high-efficiency cooling device for the manufacture of industrial automatic control system devices to solve the above problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

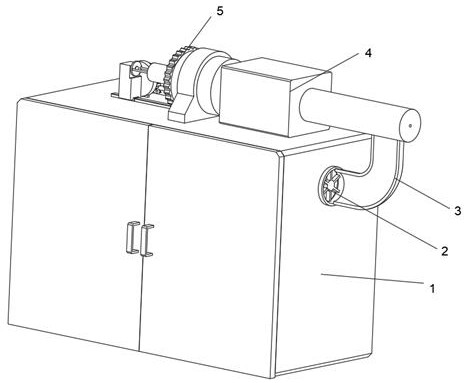

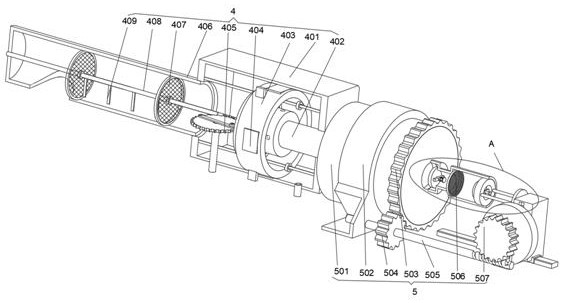

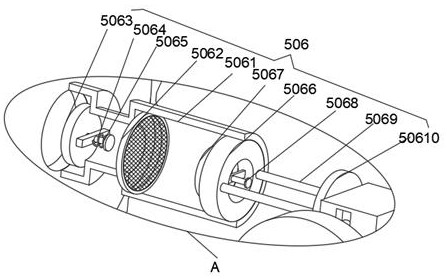

The invention relates to the technical field of efficient cooling equipment, in particular to efficient cooling equipment for manufacturing an industrial automatic control system device, which comprises an integrated cabinet, two groups of exhaust fans symmetrically arranged on two sides of the integrated cabinet, one group of exhaust fans communicated with a bent pipe, and the bent pipe connected with an air drying device with double drying and condensate water removing functions. The air drying device is connected with an air compression mechanism; the pressure relief plate is affected by air pressure, so that the pressure relief plate moves along the air outlet pipe, meanwhile, the pressure relief plate compresses the first spring through the guide shaft till the pressure relief plate moves to the head of the air outlet pipe, air columns are evenly sprayed to the inner ring of the refrigeration ring, and the air drying efficiency is improved.

Description

technical field [0001] The invention relates to the technical field of high-efficiency cooling equipment, in particular to a high-efficiency cooling equipment for manufacturing industrial automatic control system devices. Background technique [0002] The intelligent industrial automatic control system mainly realizes the integration of information management and automatic control through the induction, analysis and arrangement of various information collected by sensors and local area networks through industrial control computers, and can ensure the security of information through authorization authentication. , industrial automation is the control of various parameters in industrial manufacturing and production to achieve various process controls. In the entire industrial manufacturing and production, human operations are minimized, and energy and various information other than animals can be fully utilized for production. Work, in this type of control system, generally al...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05K7/20B01D53/26

CPCH05K7/20145H05K7/20181H05K7/20172B01D53/265

Inventor 黄星云

Owner 深圳市凌心科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com