3D printing T-shaped shoe

A 3D printing and Ding printing technology, which is applied in footwear, medical science, applications, etc., can solve the problems of poor comfort and poor matching of T-shaped shoes, and achieve the goals of preventing falling off, good fixing effect, and improving the level of fit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

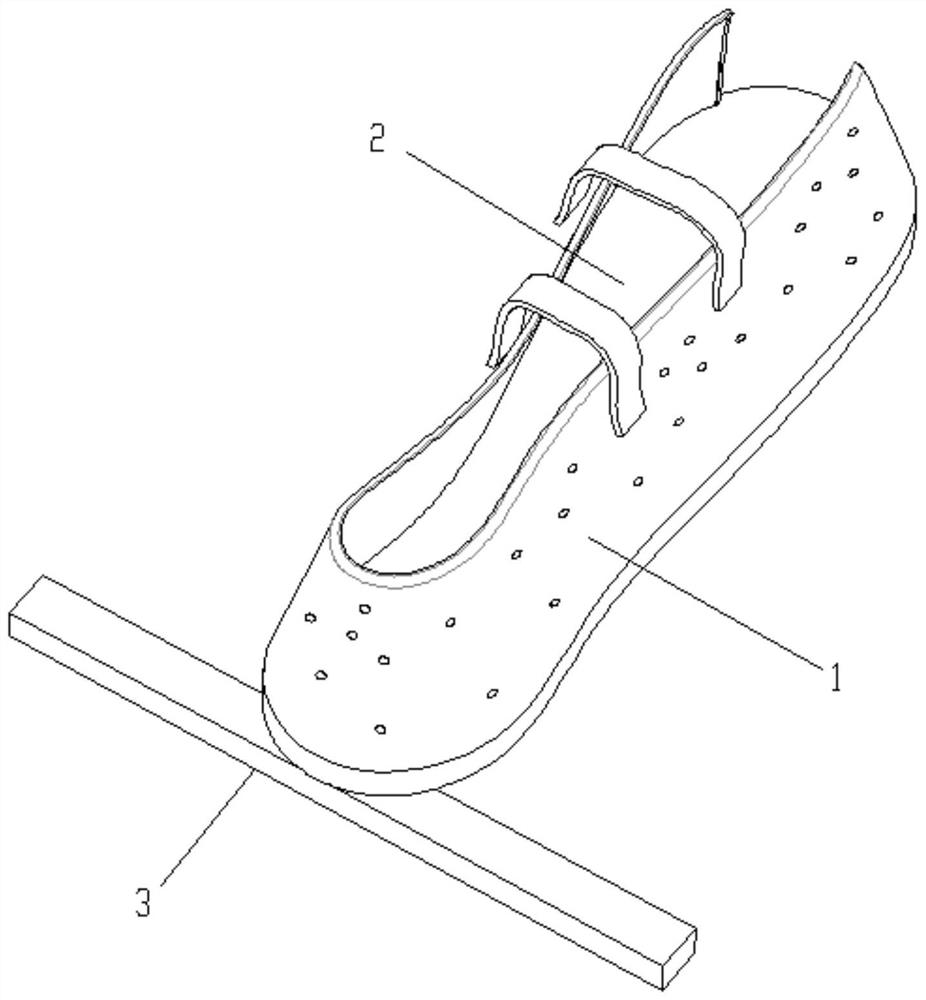

[0034] like figure 1 As shown, a 3D printed T-shaped shoe is provided, comprising an instep fixing part 1, a sole support part 2 and an ankle fixing part 3, wherein the instep fixing part is made of 3D printing, and includes an inner layer 4 conforming to the patient's foot surface And wrap the skeleton layer 5 fixed on the outside of the inner layer. Among them, the skeleton layer is a soft plastic layer, such as latex, which has a setting effect and is deformed under the action of external force, but after the external force is removed, it can be restored to its original state, so that it can wrap and fix the instep of the patient, but it will not affect the skin. cause discomfort, with better comfort. At the same time, the inner layer of this embodiment is a silica gel layer, and the silica gel has good affinity, which can form better protection for the skin, and there will be no skin problems.

[0035] When making the instep fixing part, first perform a three-dimensional...

no. 2 example

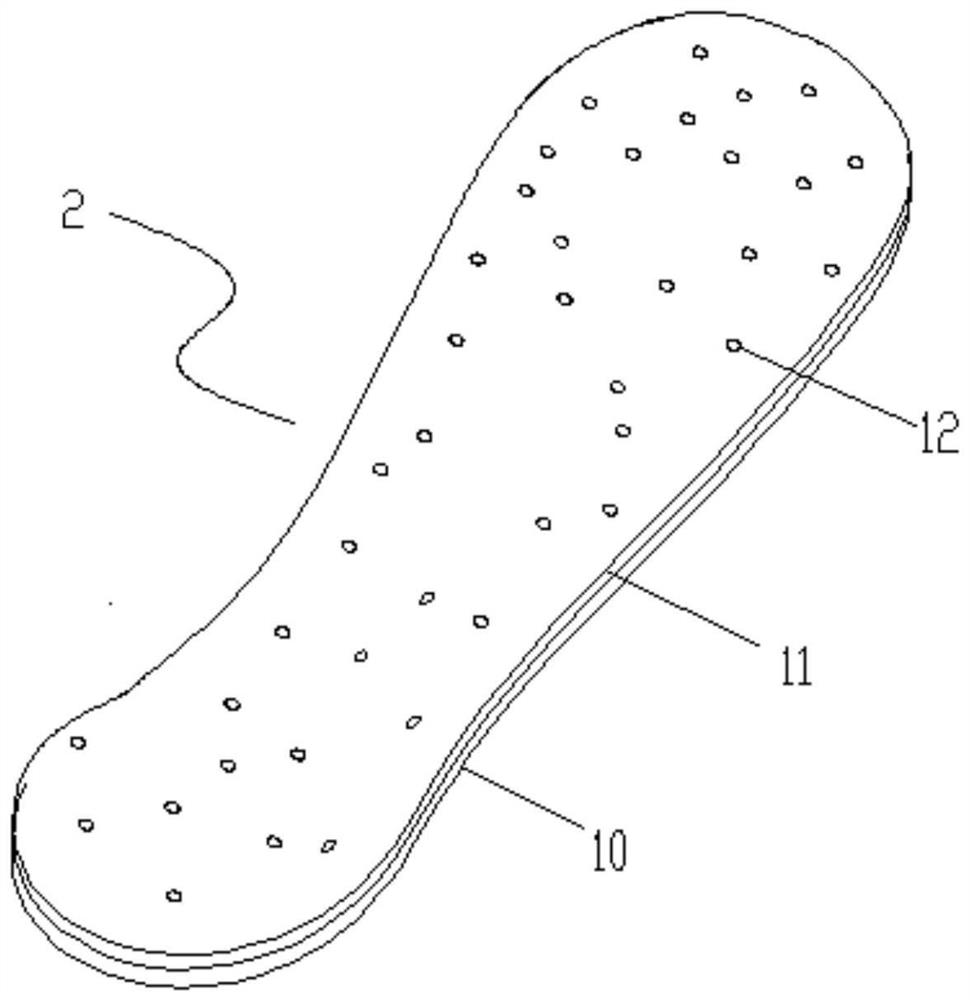

[0041] Different from the first embodiment, the sole support part of this embodiment is also 3D printed, and the sole support part is set as a double-layer structure including a support layer 10 and a bonding layer 11, such as image 3As shown in the figure, the support layer is made of flexible deformable material, so that it has a certain deformation ability and can be bent to a certain extent, so that the patient's sole can be rotated back and forth at a certain angle at the heel to perform certain activities and promote Blood circulation, prevent joint stiffness, muscle atrophy, lower extremity venous thrombosis and other complications. At the same time, the fit layer can also improve the fit with the sole of the foot and improve comfort

[0042] In this embodiment, the support layer is a soft plastic layer, such as latex, cooked glue, etc., and the adhesive layer is a silicone layer.

no. 3 example

[0044] Different from the second embodiment, the ankle fixing part of the present invention is printed, so that the T-shaped shoe can be printed in one piece, which can significantly improve the production efficiency.

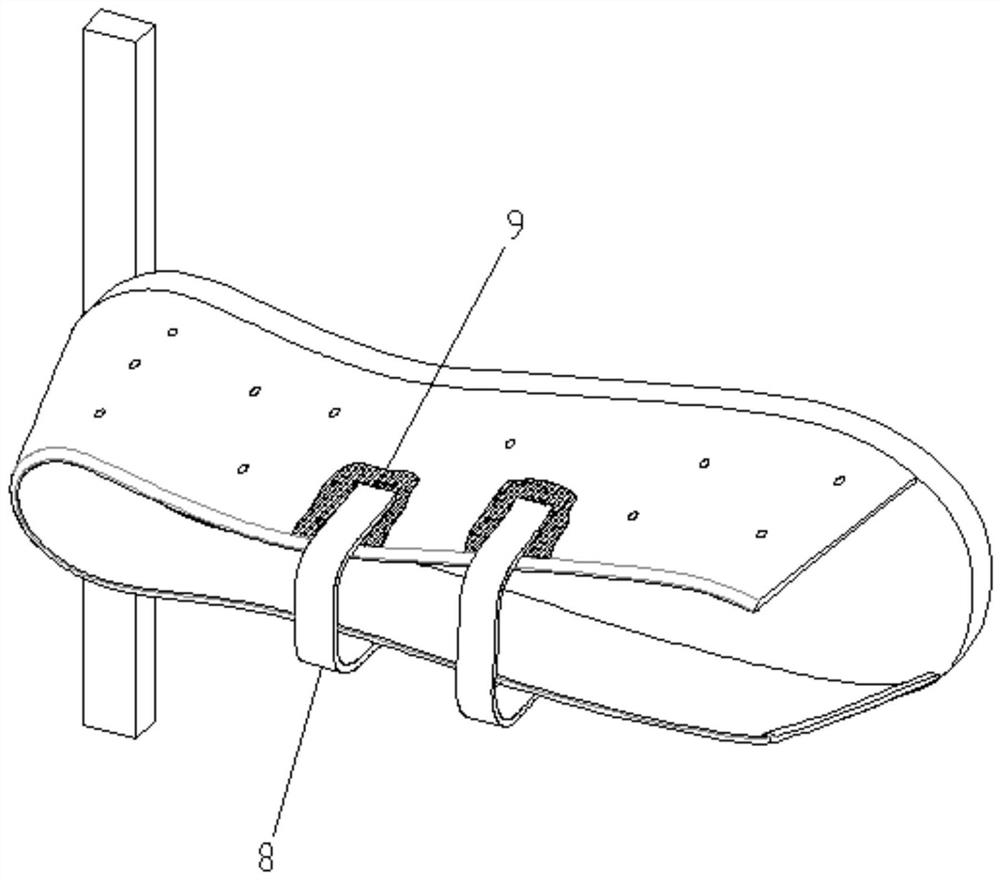

[0045] In all the above solutions, the instep fixing portion and the sole support portion are both porous structures 12 . like figure 1 , 2 , 3, the gas in the shoe can be exchanged with the outside, thereby alleviating the formation of a closed environment in the shoe and reducing the occurrence of various skin complications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com