Eluting equipment used in polypeptide production process and implementation method thereof

A production process and elution equipment technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning hollow objects, etc., can solve problems affecting efficiency, shutdown operations, etc., and achieve the effect of avoiding residue and improving elution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

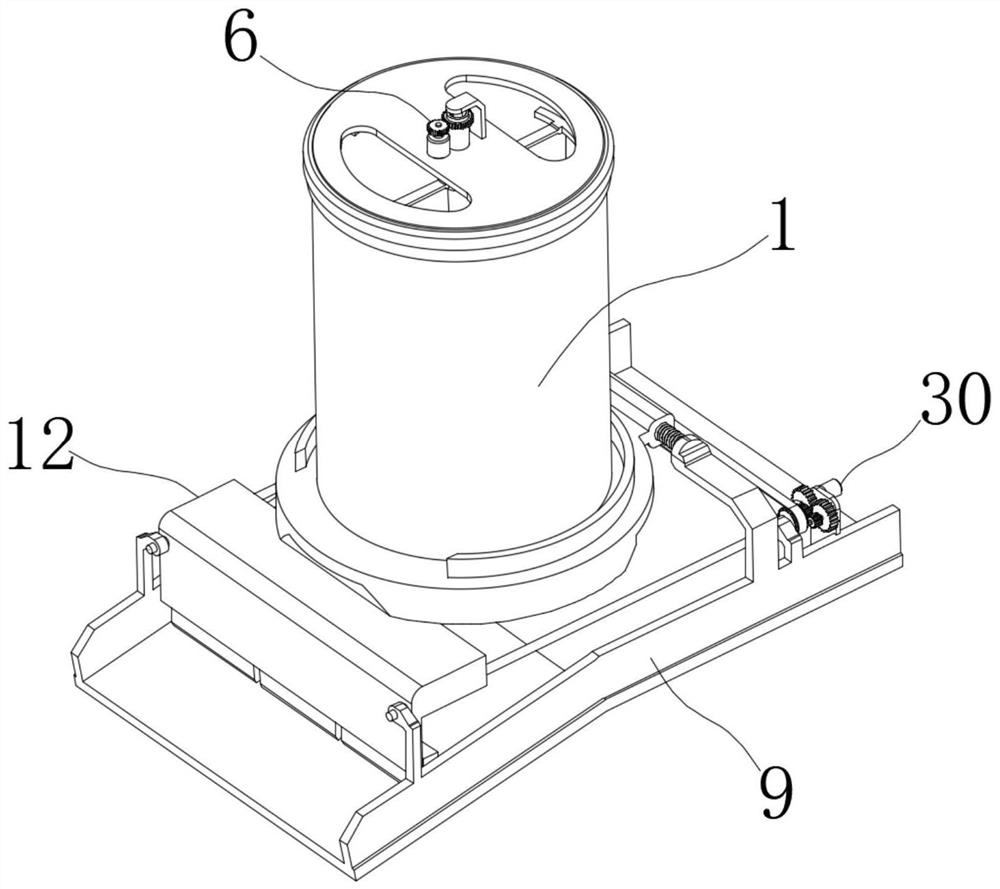

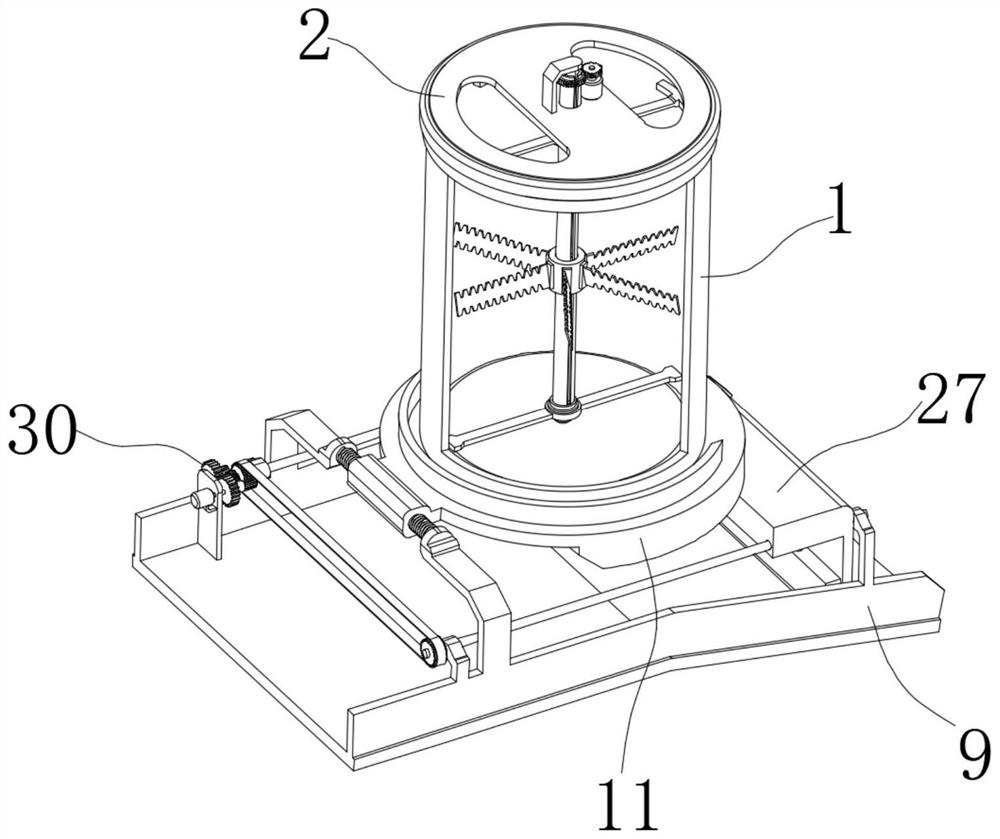

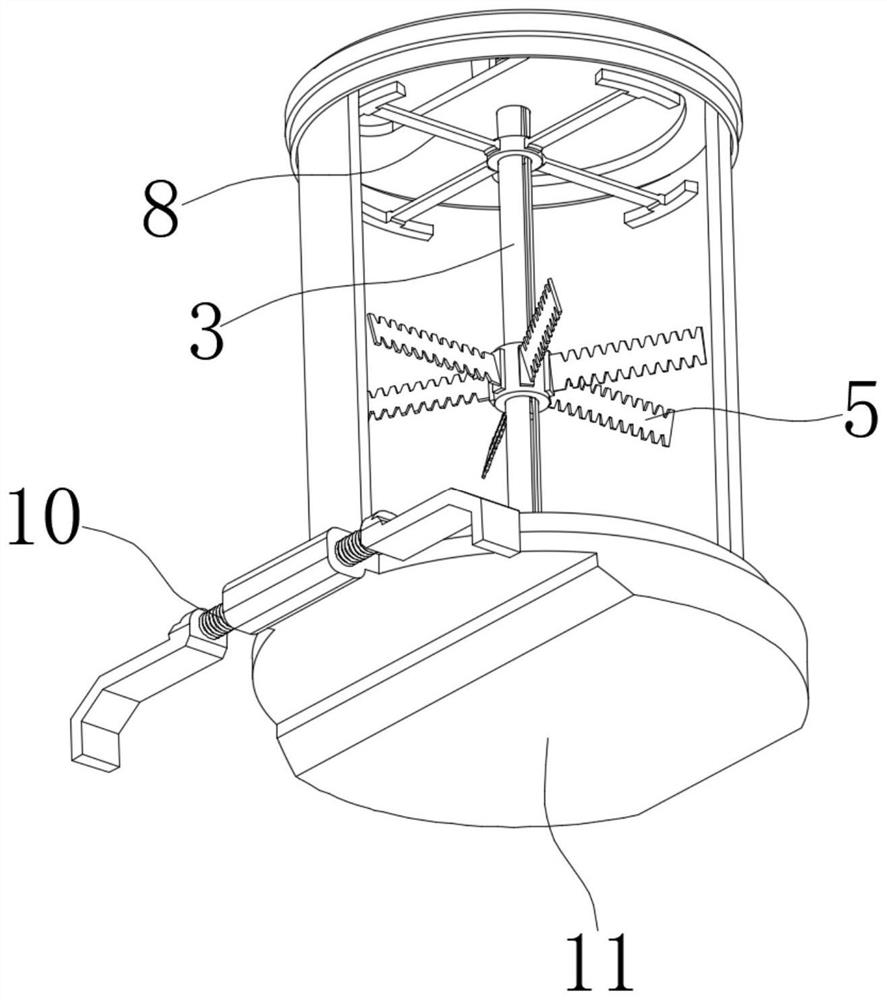

[0033] see Figure 1-Figure 3 , a kind of elution equipment used in the process of polypeptide production in the figure, including a pulverizing cylinder 1, the top of the pulverizing cylinder 1 is threaded with a cylinder cover 2 with a through hole, and the cylinder cover 2 is rotatably arranged with a rotating The pipe 3 also includes a movable seat 4 installed on the outside of the rotating pipe 3 and a discharge plate 9 located at the bottom of the pulverizing cylinder 1. The outside of the movable seat 4 is fixed with a pulverizing blade 5, which is installed on the cylinder cover 2 The driving member 6 at the top, the driving member 6 is used for the rotation of the rotating tube 3, and the rotating tube 3 is provided with a fixed shaft 7, the top of the fixed shaft 7 is fixed with the cylinder cover 2 through a bracket, and the bottom The end is fixed with the inner wall of the bottom end of the pulverizing cylinder 1 through a support plate, a cleaning member 8 is ins...

Embodiment approach

[0049] In this scheme: an implementation method of an elution device used in a polypeptide production process, comprising the following steps:

[0050] S1. Clean the desired plants, and then throw them into the crushing cylinder 1;

[0051] S2. Drive the crushing leaves 5 in the crushing cylinder 1 through the driving member 6 to crush the plants;

[0052] S3. The bottom of the pulverizing cylinder 1 is opened by moving the discharge assembly 12, and then the inner wall of the pulverizing cylinder 1 is scraped by the cleaning member 8 to realize the removal of residual materials.

Embodiment 2

[0054] see Figure 11 , this embodiment further describes Example 1, the top of the adjusting rod 17 in the figure is provided with a rotation groove, and the fixed shaft 7 is located at the position of the rotating groove of the adjusting rod 17 to fix the limit ring 24, and the limit ring 24 is fixed. A compression spring 25 is installed between the position ring 24 and the bottom of the rotating groove;

[0055] It is worth noting that, after the support table 11 is opened, the adjustment rod 17 can have a downward force through the action of the compression spring 25, so that the retraction of the two limiting plates 20 is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com