Special-shaped wood product dyeing device and dyeing method thereof

A dyeing device and wood product technology, applied in the field of wood product dyeing, can solve problems such as low work efficiency, uneven dyeing, multiple voids, etc., achieve a high degree of mechanical automation, solve dyeing difficulties, and meet dyeing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

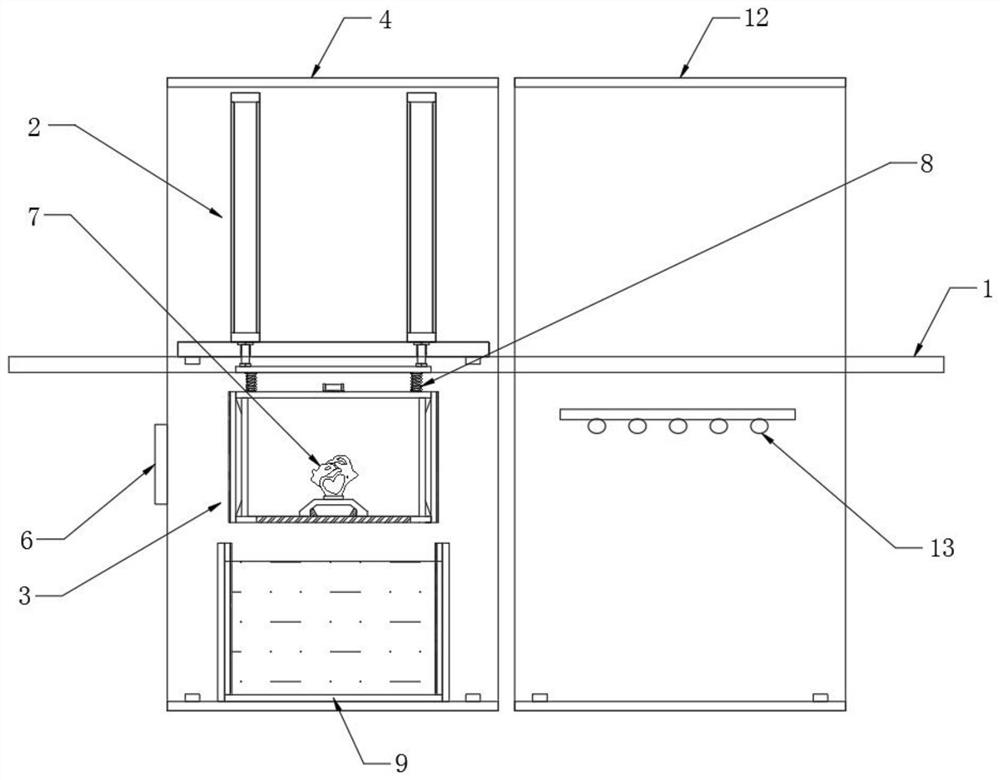

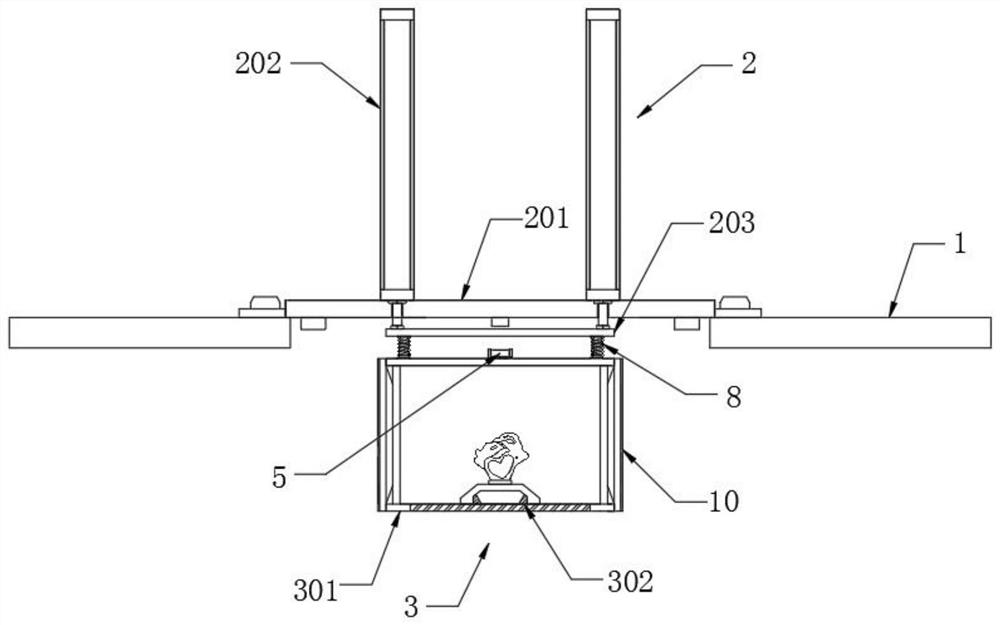

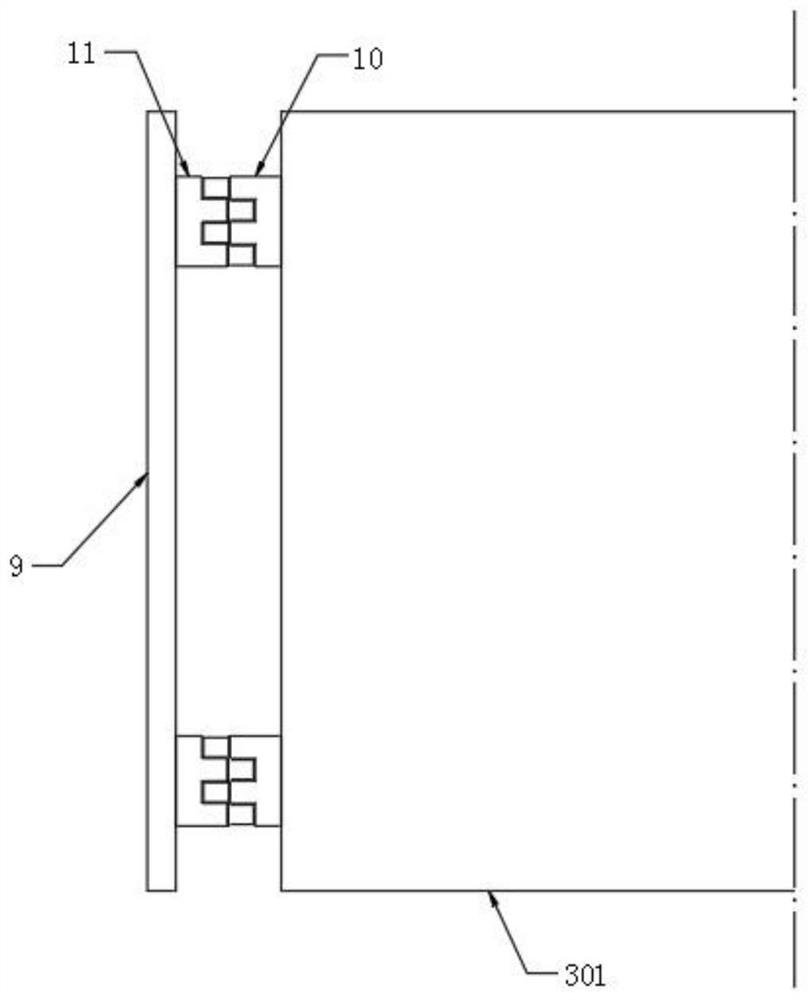

[0035] like Figure 1-4 As shown, a special-shaped wood product dyeing device proposed by an embodiment of the present invention includes:

[0036] The chain plate conveyor belt group 1 is composed of two chain plate conveyor belts synchronously and in parallel. The conveying structure of the two chain plate conveyor belts can make the load more stable and carry more reliable, so that the special-shaped wood products 7 can be transported during the conveying process. Maintain high stability and form a streamlined working method to achieve the purpose of improving work efficiency and production efficiency; there is a gap between the two conveyor belts, this structural design makes the device more reasonable, and is used for lifting mechanism 2 and wood products. The arrangement of the device 3 provides corresponding space;

[0037] The lifting mechanism 2 includes a carrier plate 201 mounted on the chain plate conveyor belt group 1 and a lifting cylinder 202 fixedly mounted on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap