Blended color yarn spun by pure spinning or blended spinning of soybean fiber and its production method

A technology of soybean fiber and production method, which is applied to yarn, textile and paper making, etc., can solve the problems of single color structure of yarn and cannot adapt to individual consumption, etc., and achieve the effect of flat surface, good drape, and light and comfortable wearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

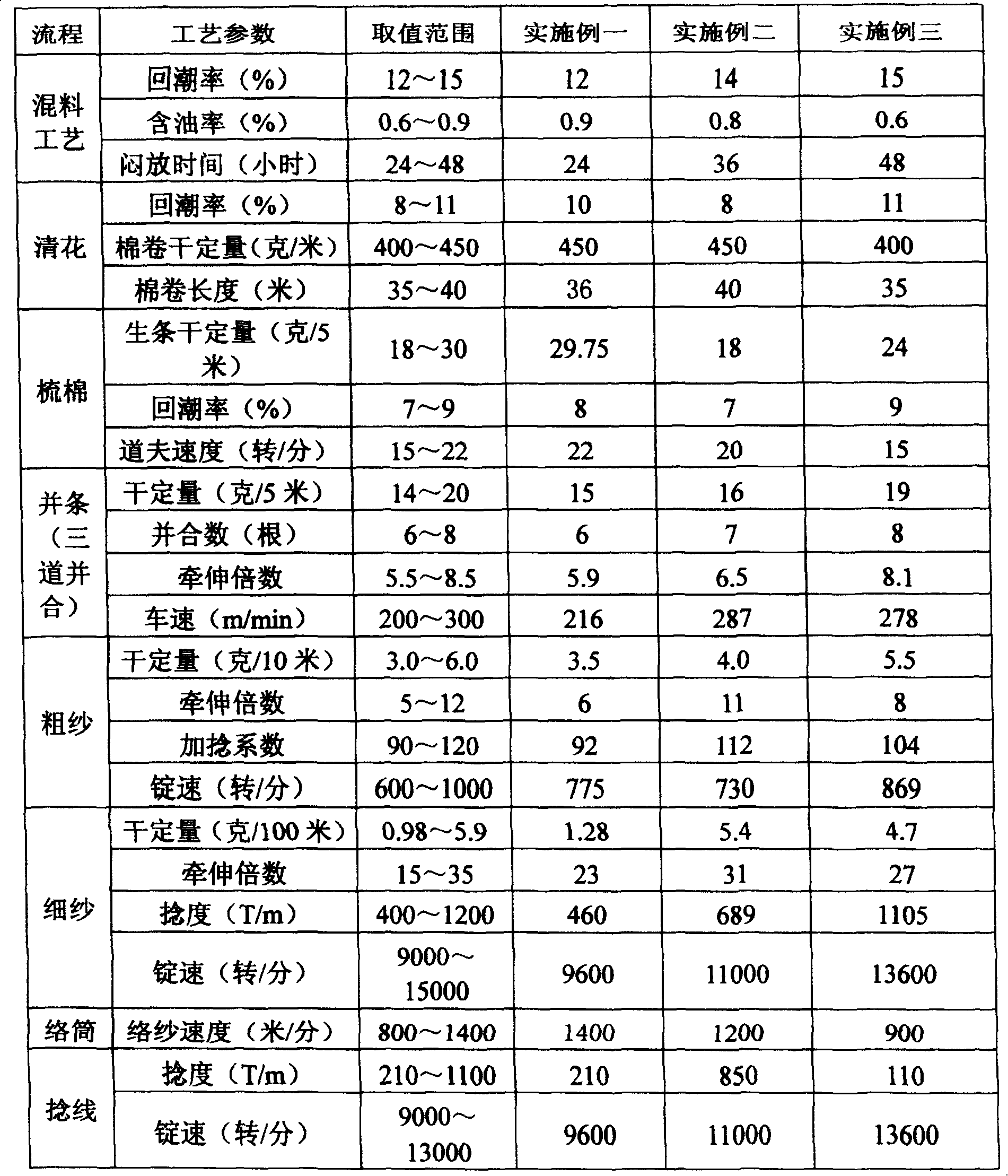

[0021] The present invention is specifically illustrated by three examples below. Its processing process is: fiber decolorization and bleaching, dyeing, weighing, soybean fiber oiling pretreatment, mixing, cleaning, carding, first doubling, second doubling, three doubling (combined with toning and complementary colors), roving, spun yarn, Winding, after the winding process, then twisting and winding.

[0022] Among them, according to the product requirements, the soybean fiber is bleached, decolorized, dyed, so that the fiber has various colors that meet the requirements; according to the product color requirements, the proportion of different raw material color fibers is matched. After the fiber is weighed, the soybean fiber is piled up separately from other fibers. The stuffed soybean fiber and other fibers are layered and mixed according to the blending ratio, and then mixed in a small amount of cotton. If the batch is large, they are evenly divided into several groups for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com