A kind of uniform color high tenacity plastic film and its preparation process

A plastic film and high toughness technology, applied in the field of uniform color and high toughness plastic film and its preparation, can solve the problems of high moisture permeability, poor barrier property, moisture absorption, etc., and achieve high hydrophobicity and improve the effect of hydrophobic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] DETAILED polyamide materials hydrophobic preparation as follows:

[0027] Step 1 Weigh 1mol acryloyl chloride was added 1L acetone solution was then added thereto 10g chloroplatinic acid hexahydrate mixed uniformly added thereto 1.02mL trimethoxysilane, the reaction was warmed to 50 deg.] C under reflux for 2-3h, then distilled under reduced pressure to give acid chloride siloxane group;

[0028] Step 2, the silicone-based acid chloride prepared in Step 1 was added 1mol autoclave, to which was then added 900mL of 3% concentration of sulfuric acid solution was added thereto while between 1mol5- hydroxy acid, the reaction was stirred at room temperature 14-15h, then filtered washing and drying, to give a siloxane diacid benzene;

[0029] Step 3, the silicone diacid benzene 100g prepared in Step 2 was added to 600mL thionyl chloride solution, stirring the reaction was warmed to 60-70 ℃ 8-10h, and then thionyl distillation under reduced pressure to remove unreacted sulfone, sil...

Embodiment 2

[0033] Specifically the polyamide material prepared as follows:

[0034] Step 1, 100g of isophthalic acid was added to 600mL thionyl chloride and heated to 60-70 deg.] C The reaction was stirred for 8-10h, and then thionyl chloride was distilled under reduced pressure to remove the unreacted benzene to obtain 5-hydroxy dichloride;

[0035]Step 4, the isophthaloyl chloride prepared in Step 3 was added to 100g of chloroform was added and dissolved with stirring autoclave, reactor temperature control is 8-12 deg.] C, and then slowly added 34g of sodium azide, stirred after 2-3h the reaction was slowly warmed to 60-90 deg.] C, and then rotary evaporated under reduced pressure and silica gel was added to the powder powder to a reaction vessel, and then to give m-phenylene diisocyanate passed through the column by petroleum ether;

[0036] Step 5, isophthaloyl diisocyanate prepared in Step 4 was added 100g of acetone, 41g of ethylene glycol was added thereto and the solution was heated ...

Embodiment 3

[0038] The specific preparation process of surface functionalized dyes is as follows:

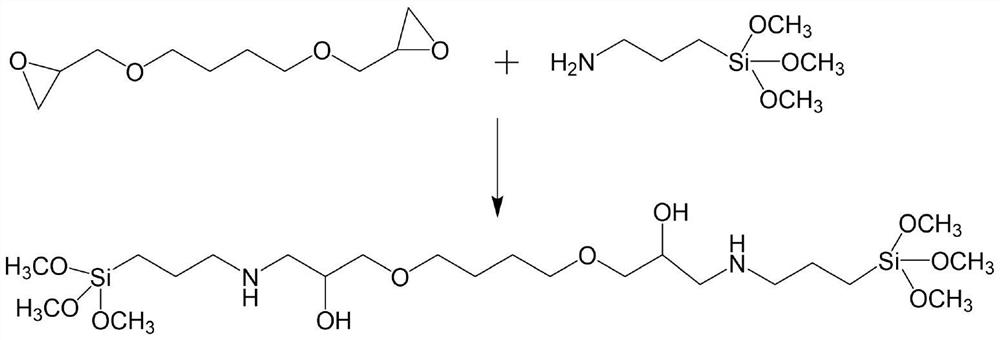

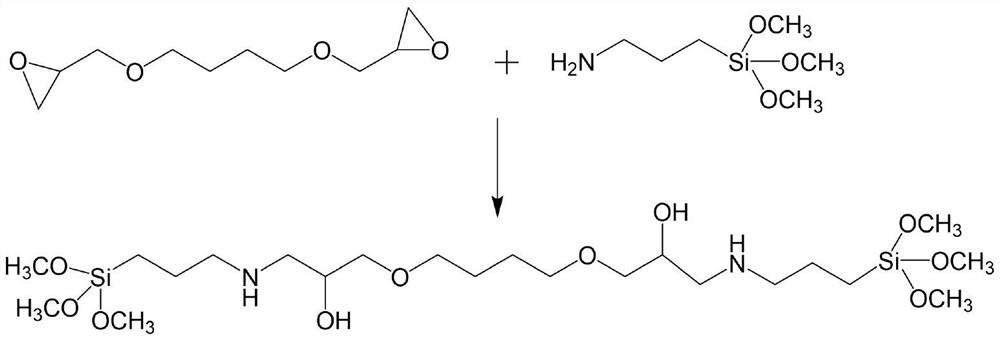

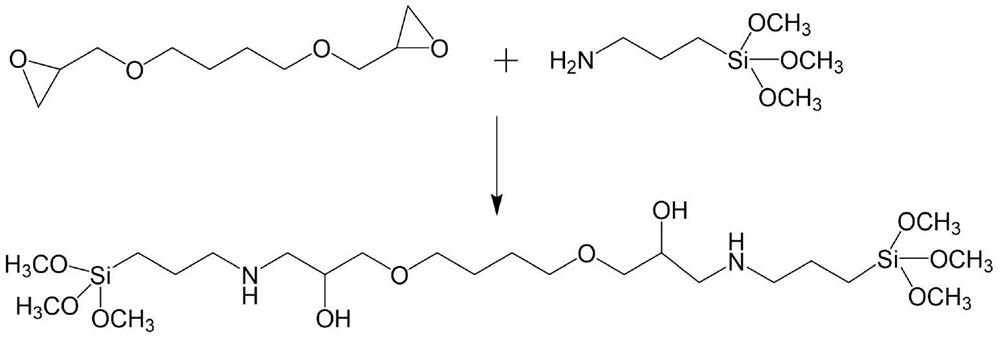

[0039] ① weighed 1mol1,4- butanediol diglycidyl ether and 1L of acetone was added while the reaction vessel, to which was then added 1mol3- aminopropyl trimethoxysilane, stirring the reaction temperature was raised to 60-70 ℃ 2-3h, then Save pressure distillation, to obtain the modifier, the following reaction formula;

[0040]

[0041] Weigh 10g ② inorganic dyes added to the kettle, and then 100mL of water was added thereto with stirring mixed, followed by addition of 2.3g modifier prepared in step ① to the kettle and heated to reflux for 8-10h 90-100 deg.] C, then filtered washing and drying, to obtain surface-functionalized dye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com