Demolding device for foam plastic molding machine and demolding method thereof

A demolding device and molding machine technology, applied in the field of foamed plastic products, can solve the problems of easy breakage, increased damage rate of foamed plastics, broken and perforated foamed plastics, etc., so as to improve the integrity rate, avoid force clamping, reduce stress The effect of force damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

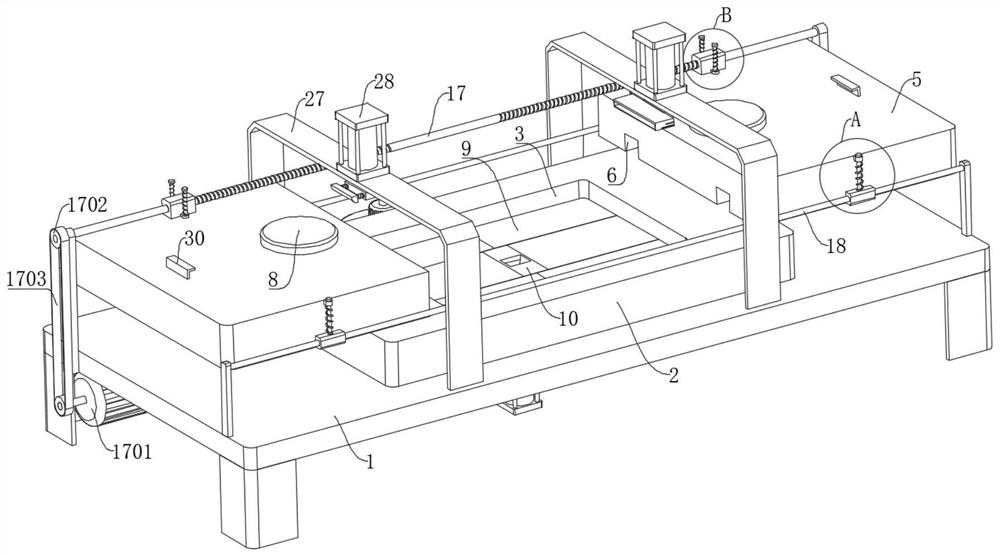

[0049] As an embodiment of the present invention, the opening blocking mechanism includes a first cylinder 15 , the first cylinder 15 is fixedly installed at the bottom of the feed shell 10 , and the end of the telescopic section of the first cylinder 15 penetrates through the bottom of the feed shell 10 and After extending to the inside of the feeding cavity 11, a blocking block 16 is fixedly connected, and the blocking block 16 is adapted to the injection port of the feeding cavity 11; during operation, when the feeding is finished, the first cylinder 15 is activated, and the first cylinder The output shaft of 15 drives the blocking block 16 to move, and the blocking block 16 moves upward along the feeding cavity 11. The top of the blocking block 16 is flush with the top of the opening of the feeding cavity 11, thereby blocking the opening of the feeding cavity 11. And make the top of the feeding shell 10 smooth and flat, while ensuring the feeding, it is beneficial to keep t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com