Lubrication stacking machine portal frame assembly

A technology for stackers and components, applied in the field of stackers, can solve the problems of dangerous, difficult, and high gantry in lubrication, and achieve the effect of avoiding personal danger and ensuring lubrication and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings, so as to make the technical solutions of the present invention easier to understand and grasp.

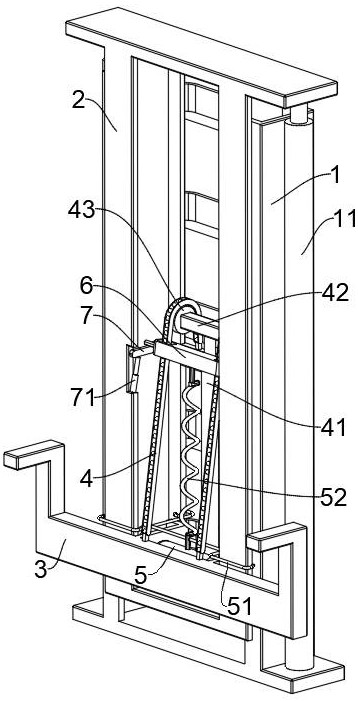

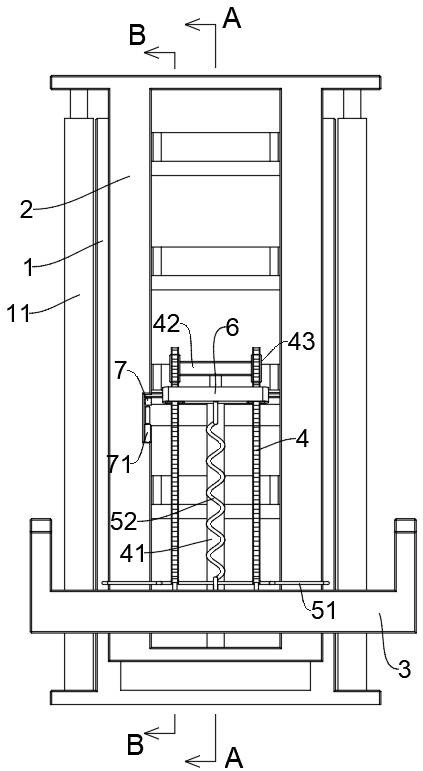

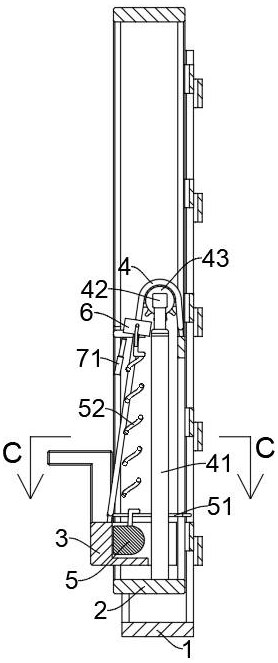

[0026] This embodiment provides a lubricated stacker gantry assembly, refer to figure 1 , figure 2 and image 3 As shown, it includes an outer gantry 1 and an inner gantry 2, the inner gantry 2 is sleeved in the outer gantry 1, and the outer gantry 1 is provided with a mechanism for driving the inner gantry 2 to slide up and down The inner gantry 2 is provided with a fork 3 for grabbing and lifting containers, and a vertical inner hoisting cylinder 41 is fixed at the bottom of the inner gantry 2. The inner hoisting cylinder 41 The upper end of 41 is fixedly connected with a support rod 42, the left and right ends of the support rod 42 are rotatably provided with two sprockets 43, and the two sprockets 43 are meshed and sleeved with a cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com